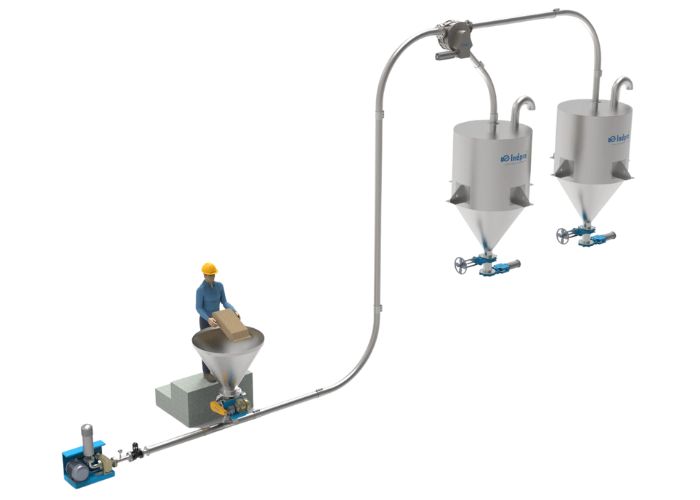

Dilute Phase Pneumatic Conveying System (Vacuum)

Indpro is a leading solution provider for customized vacuum-based dilute phase pneumatic conveying systems. We are providing solutions according to the requirement of the industry. Our solutions are totally customized as per the requirements of different industries. Vacuum based dilute phase pneumatic conveying systems are installed primarily where multiple feed points are involved. Dilute phase conveying systems are usually provided when particle size distribution varies from microns to millimeters.

The dilute phase conveying system has its application in chemical, food, pharmaceuticals, plastic, polymers, and breweries. The dilute phase conveying systems are usually provided when particle size distribution varies from microns to millimeters.

This lean phase pneumatic conveying system is low-pressure high-velocity systems that have the utmost flexibility

for the kind of range of materials that can be handled. The airflow is generated with vacuum pumps, centrifugal

fans or blowers. There is a wide range of materials that can be conveyed in the dilute phase pneumatic conveying system.

Dilute phase Vacuum Conveying is a suspension flows wherein the material to be conveyed is introduced into a moving air stream inside a pipeline.

The transport gas velocities are in the range of 15 - 30 m/s depending on the product characteristics.

It uses high velocity, low pressure, and low product to air ratios.A well designed pneumatic conveying system will have this

velocity well optimized and hence will minimize energy consumption. The conveyed product is totally dispersed in the gas flow.

These pneumatic conveying systems are popular for short distance powder conveying in food, chemical and

pharmaceutical industries. Materials are taken into high-velocity gas stream by utilization of rotary airlock valves

and carried through the pipeline from point A to point B.

Product Features

Specification

-

Conveying Rate

Low to High, typically from 1 - 40 tons/hr

-

Conveying Velocity

15 m/s - 25 m/s

-

Conveying Distance

Upto 100 - 200 mtrs

-

Air Mover

Positive displacement tri-lobe blower / ID fan / Ring channel blower

-

Operating Pressure

Upto -500 mbar(g)

-

Solids Loading Ratio

1 to 10

19+years of

Automating your bulk material transfer

Looking for something more?

Our Dilute Phase Pneumatic Conveying System can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USRelated Products

There are many more products and systems which you can explore

Pneumatic Conveying System FAQ's

The basic components of a pneumatic conveying system include:

Feed hopper: The feed hopper is the starting point of the pneumatic conveying system. It is where the material to be conveyed is loaded into the system. It can be a simple container or a more complex storage device which may perform more than one function. There is usually a valve that follows the feed hopper that helps to regulate the flow of material into the system.

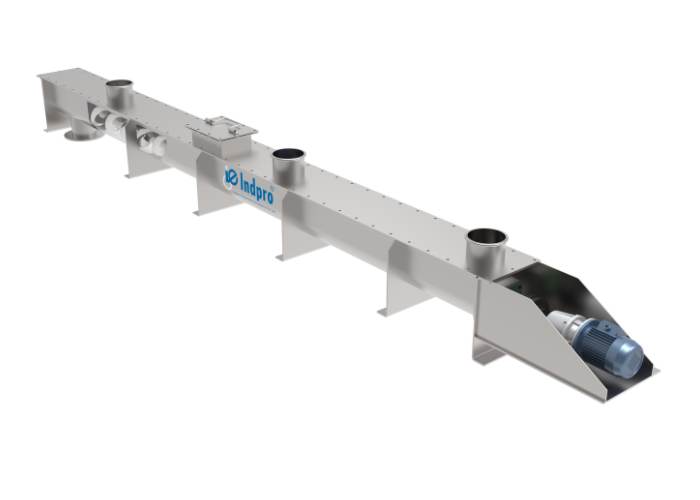

Conveying pipeline: The conveying pipeline is the longest component of any pneumatic conveying system. It carries the material from the feed hopper to the discharge point. The pipeline can be made of either rigid or flexible materials such as steel, aluminium, PVC, PU, etc, depending on the application. The pipeline can be a single pipe routing or a complex network of pipes, depending on the design of the system.

Compressor or blower (air mover): The compressor or blower is the most important device that generates the air flow needed to transport the material through the pipeline. It can be a positive displacement compressor or a centrifugal blower. The type of compressor or blower used depends on the specific requirements of the application.

Product air filter: The product air filter is a device that separates the product from air before it is exhausted to the atmosphere at the end of conveying. The unit can be paired with a cyclone or remain standalone depending on the dust load and separation efficiency required.

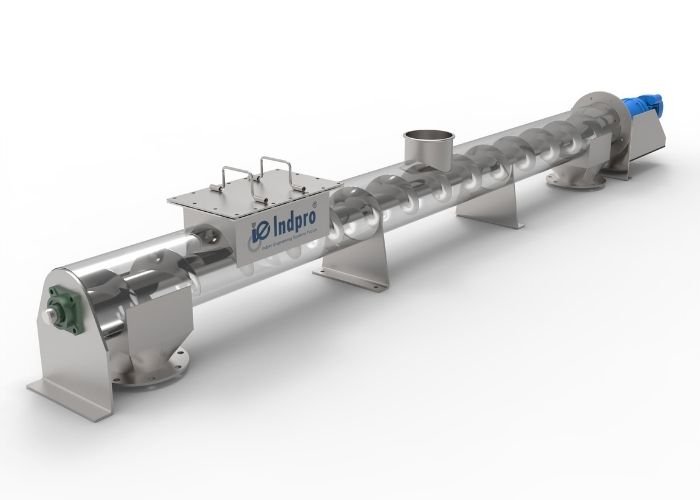

Product feeder: The product feeder is a device that controls the density of the material in the air stream by adjusting the air-to-material ratio. It can be a simple valve or a more complex device, such as a rotary feeder, that regulates the flow of material into the system.

Flow control valves: The flow control valves regulate the flow of air through the system. They can be manual or automatic valves that are used to control the flow rate and pressure of air.

Pressure and vacuum gauges: The pressure and vacuum gauges are devices that measure the pressure and vacuum in the system to ensure optimal performance. They can be used to monitor the pressure at various points in the system and to adjust as necessary.

Discharge point: The discharge point is the point at which the material exits the system. It can be a silo, a baghouse, or another storage container. The discharge point is typically located at the end of the conveying pipeline and is responsible for collecting and storing the conveyed material.

Control system: The control system is the system that controls the operation of the pneumatic conveying system, including the air mover, flow control valves, and product feeder. It can be a simple manual control system or a more complex automated system that uses sensors and computer controls to regulate the operation of the system.

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry