Bin Activator: The Key Solution to Powder Bridging and Flow Problems in Bulk Material Handling

Bin Activator: The Key Solution to

Powder Bridging and Flow Problems

in Bulk Material Handling

From stuck silos to seamless flow — here’s how one smart device is making all the difference.

In the world of bulk material handling, smooth and consistent flow isn’t just ideal—it’s essential. Yet, if you’ve ever faced issues like powders getting stuck in silos, erratic material discharge, or costly downtime, you’re not alone. These problems are more common than you think—and there’s a smart solution that solves them at the root: the Bin Activator.

Let’s dive into why this simple yet powerful device is revolutionizing flow problems for industries across the globe.

The Challenge: Why Material Flow Is Not Always Smooth

Handling bulk materials like powders, granules, and flakes seems straightforward—until things start to jam. Here are some of the most frequent issues industries face:

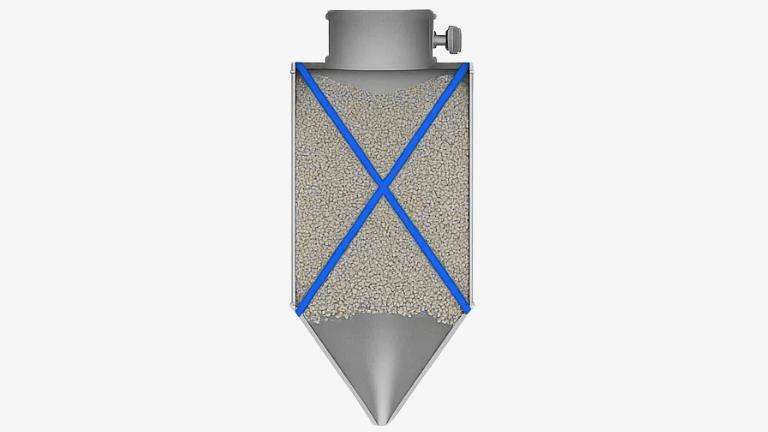

1. Bridging

Bridging refers to the formation of an arch-shaped blockage that interrupts material discharge.

2. Ratholing

Rat-holing happens when material flows through a narrow central path, leaving the surrounding bulk unmoved.

3. Material Segregation

Particles of different sizes or weights separate, impacting quality.

4. No Flow or Erratic Flow

Leads to inconsistent production and manual intervention.

These challenges cause downtime, product wastage, and maintenance headaches, all of which eat into your profits.

The Hero of the Story: What is a Bin Activator?

A Bin Activator is a flow aid device mounted to the bottom of silos or hoppers. It uses controlled vibration to keep material moving consistently and prevent common flow issues.

At first glance, it may just look like a metal cone with a motor—but don’t let the simplicity trick you. It’s engineered to deliver consistent results for even the most stubborn materials.

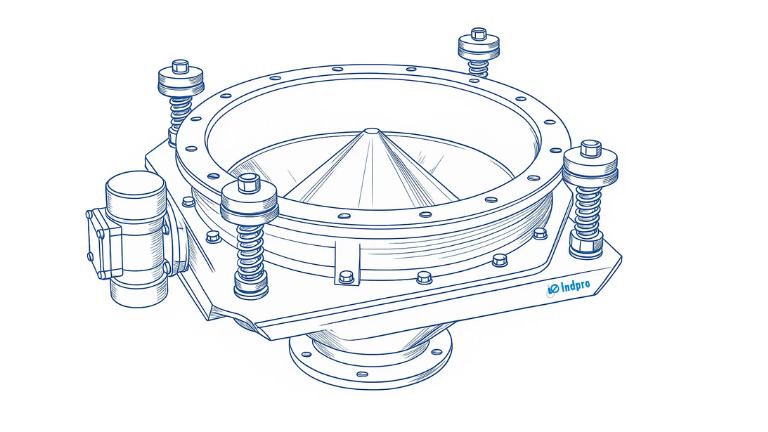

Key components:

- Sloped cone to direct flow

- Suspension arms to isolate vibration

- Vibratory motors that apply controlled vibration to loosen material and promote flow.

- Flexible seal to maintain airtightness while allowing movement

How Does a Bin Activator Actually Work?

Think of the Bin Activator like a gentle tap that keeps materials in motion—only smarter and more efficient. Here’s how it works:

- Material is directed into the cone-shaped region for efficient flow initiation.

- The vibratory motor creates motion that loosens compacted or stuck particles.

- Vibration breaks bridges and rat-holes, letting the material flow freely.

- The result? Delivers consistent, first-in-first-out flow—completely automated, no manual input required.

What Materials Work Best with Bin Activators?

Not all materials behave the same—but that’s the beauty of bin activators: they’re highly versatile.

✅ Fine powders like flour, cement, fly ash

✅ Cohesive materials like talc or carbon black

✅ Fragile granules that shouldn’t be broken

✅ Hygroscopic materials that clump easily

✅ Heat- or oxygen-sensitive products that can’t be agitated with hot air

No matter the material—if it clogs, bridges, or just won’t flow—a bin activator is likely the fix.

Why Bin Activators Are Better Than Other Flow Aids

There are many ways to “force” material out of a hopper—air cannons, vibrators, fluidizing pads—but none match the consistency and control of a bin activator.

Feature | Bin Activator | Aeration Pads | Air Cannons | Vibrators |

Suitable for cohesive materials | ||||

Controlled flow rate | ||||

Maintenance requirement | Low | Moderate | High | Moderate |

Energy consumption | Moderate | High | High | Low |

Material degradation risk | Low | High | High | Low |

Benefits You’ll Notice Instantly

🔹 No bridging or rat-holing

🔹 Consistent, predictable discharge

🔹 No material degradation

🔹 Low power consumption

🔹 Reduced operator intervention and downtime

🔹 Longer equipment life and minimal maintenance

Real-World Example: A Chemical Plant's Flow Nightmare Fixed

One of our clients in the chemical industry was dealing with frequent blockages in a silo storing a cohesive powder. They tried everything—from air pads to manual poking.

After installing an Indpro Bin Activator, the flow issues disappeared overnight. Downtime dropped by 60%, and their batch consistency improved significantly. The team could finally focus on production instead of maintenance.

Why Choose Indpro’s Bin Activator?

At Indpro, we don’t offer a “one-size-fits-all” solution. Our Bin Activators are:

✔️ Custom-designed based on your material characteristics

✔️ Built for performance – heavy-duty construction, industrial-grade vibration system

✔️ Designed to be dust-tight and hygienic, – with food-grade variants available.

✔️ Proven in the field – trusted by clients in plastic, chemical, food, and pharma industries

✔️ Guided by experienced engineers through design, setup, and long-term operation.

Conclusion: Smooth Flow = Smoother Operations

Don’t let material flow issues slow you down. A Bin Activator is one of the smartest investments you can make in your bulk material handling system. A silent performer, it tackles challenges and enhances system reliability.