How is plastic recycled

How is plastic recycled?

Turning Trash into Treasure

Do you know what happens with various plastic bottles that you use once and throw away?

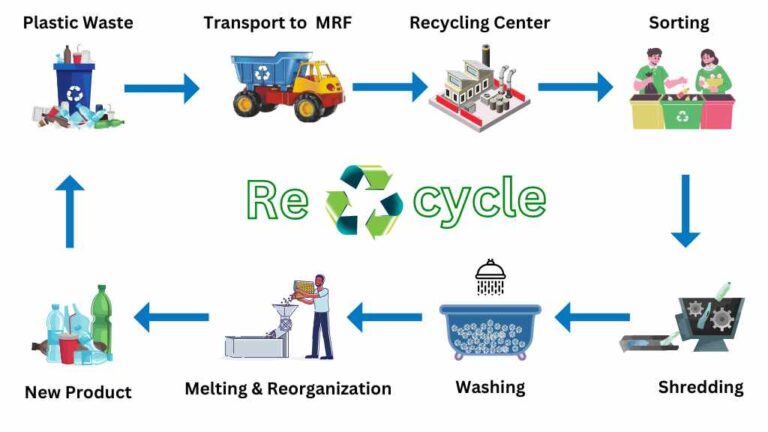

Plastic is one of the most widely used materials in the world, but it also poses a significant environmental threat due to its non-biodegradable nature. Recycling plastic is a crucial step in reducing its negative impact on the environment. In this blog, we will discuss how plastic is recycled and the role of silo storage and pneumatic conveying systems in the process.

Step 1: Sorting

The first step in the plastic recycling process is sorting. Plastic waste is collected from various sources, such as households, industries, and commercial establishments, and transported to a recycling facility where it is sorted based on its type. Sorting is essential because different types of plastics have different properties and cannot be recycled together. Sorting is a crucial step in plastic recycling and can be done manually or with the help of machines. Manual sorting involves visually inspecting and separating plastic waste into different categories such as PET, HDPE, PVC, LDPE, and others. Machines such as conveyor belts, infrared sensors, and air classifiers are used for automated sorting.

Step 2: Shredding

The sorted plastic waste is then shredded into small pieces using machines such as granulators or shredders. Shredding makes it easier to handle and transport plastic waste to the next stage of the recycling process. The shredders use high-speed rotating blades to cut the plastic waste into small pieces. The size of the shredded pieces depends on the type of plastic waste and the desired product.

Step 3: Washing

The next step in the recycling process is washing. The shredded plastic is washed in hot water to remove any dirt, debris, and other impurities. The plastic is then dried using centrifugal force or hot air. The washing process removes any contaminants from the plastic waste, making it ready for further processing.

Step 4: Secondary sorting

After washing and drying, the plastic is once again sorted based on its type and color. This step ensures that the recycled plastic is of high quality and free of cross contamination. It can be used to make new products. The sorted and processed plastic waste is stored in large silos to protect it from environmental elements such as moisture, dust & heat. The plastic waste, either pre-sorted or post-sorted, can be transported from the sorters to silos or from silos to extrusion area using a pneumatic conveying system. This system uses air pressure to move the plastic waste through a network of pipes and into the extruder.

Step 5: Melting and Extrusion

In the next stage, the sorted plastic is melted and extruded into long tubes or strands. The melting process is done in a large machine called an extruder. The extruder consists of a screw that heats and melts the plastic as it moves through the machine. The extruder also shapes the molten plastic into a continuous tube or strand.

Step 6: Pelletization

The extruded plastic is then cut into small pieces called pellets. Pelletization makes it easier to transport and store the plastic. The final plastic pellets are stored either in 25 kg bags or 500 to 1000 kg jumbo bags for easy transportation which are filled semi-automatically or automatically using bagging machines. The pellets are uniform in size and shape and can be easily melted and molded into new products.

Step 7: Making New Products

The final stage in the recycling process is the manufacturing of new products. The pellets are transported to factories where they are used to make a variety of products such as plastic bags, containers, and bottles. The pellets are melted and molded into the desired shape using machines such as injection molding machines or blow molding machines. The finished products are then sent for quality control checks to ensure that they meet the required standards. The products made from recycled plastic are cost-effective and eco-friendly, and they help in reducing the amount of plastic waste that ends up in landfills or oceans.