Why is bulk material handling automation required in your plant?

Why is bulk material handling automation required in your plant?

Optimizing the first mile, like most processes, is made possible by technology, but it takes the right tools to fully automate your manufacturing process plant. Advanced manufacturers recognize that the first mile of automation begins with how raw materials are received, stored, and transported from the moment they enter a facility.

Manufacturers are constantly under pressure to produce goods more quickly and at a lower cost, but never at the cost of quality. Of course, any technology expenditure made to achieve these objectives must have a positive return on investment.

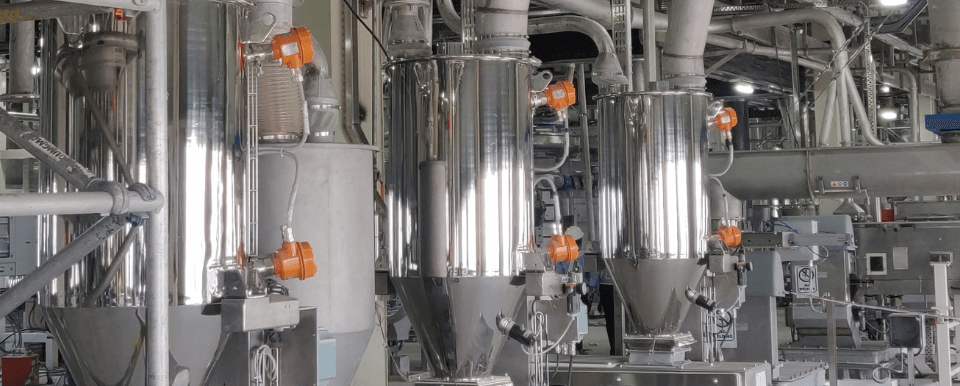

Bulk material handling automation services offer a single point of contact for all your raw material handling automation needs. Bulk material handling automation equipment is commonly found in industrial plants where mass production entails the use of heavy gear to transform raw materials into consumable goods. Automated bulk raw material handling equipment is used by businesses because it helps all process industries enhance their productivity, eliminates waste & increases safety in terms of raw material handling which results in significant cost savings. In the production process, material handling automation equipment lowers the requirement for human intervention. As a result, there is less chance of human error or damage.

This type of machinery is frequently employed for tasks that would otherwise be beyond a human’s physical capabilities, such as transporting material in bulk quantities or working with hazardous or explosive materials.

Applying automated bulk material handling technology to any industrial plant’s network results in significant cost reductions and a quick return on investment. Automated raw material handling, conveying, storing, weighing and batching and bagging of bulk materials helps in achieving excellence in process flow management, product production planning, resource allocation, forecasting, ensuring repeatability, customer delivery, and control.

What is an automated bulk material handling system, and how might it

help your plant become more productive?

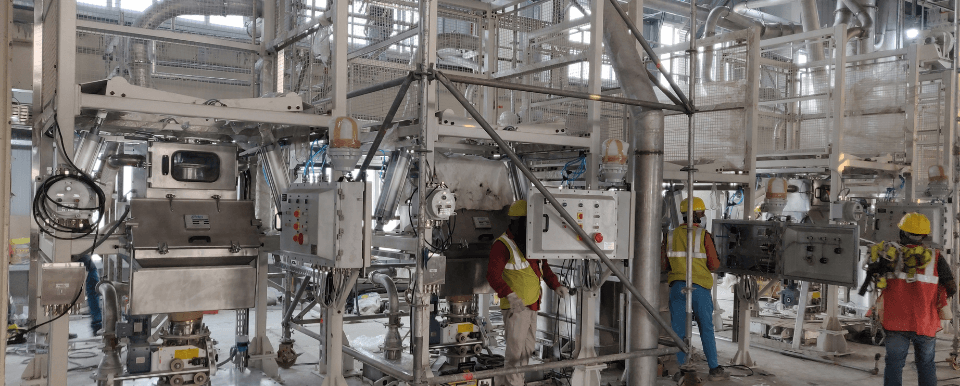

Your raw material handling systems control everything from how you keep your raw materials to how they convey across your process plant to achieve your finished product. Bulk material handling management is a key function in raw material handling, so make sure you’re transporting your bulk material as efficiently and cost-effectively as possible. When you start looking into your alternatives, you’ll notice that there is a lot of different bulk material handling systems to choose from. Bulk material handling can be done manually, automatically, or in a combination of both.

To assist you in selecting the best bulk raw material handling systems for your plant, we will go through the benefits and drawbacks of bulk material handling automation systems, as well as how they can benefit you. So, how about we have a look?

The raw material is efficiently delivered from one point in the manufacturing area to another to produce goods, whether inside the same department or bay, on opposite sides of the manufacturing floor, or even in two distinct buildings, thanks to automated bulk material handling systems. An automatic bulk material handling system uses the route and process step information from the MES to transfer raw materials utilizing either technology involving pneumatics or mechanical systems.

One of the most important requirements in a bulk raw material handling system is to optimize processes, get more control and efficiency, and so become more competitive. Furthermore, it is a fact that each industry encounters unique hurdles in providing a product of the quality that your client wants.

Manufacturers can reap numerous obvious and verifiable benefits from automated bulk material handling systems, such as lower operating costs and higher material throughput, enhanced productivity, and safety in terms of material handling but the benefits can go even further.

About Automation in Bulk Raw Material Handling

When we talk about bulk material handling, we are referring to the complete process of moving raw materials from one location to another, protecting raw materials, storing, weighing & batching into and between various material processing equipment. It also covers bagging of bulk material of finished goods. Consumption, distribution, positioning, and disposal of raw materials are all part of the process. Various types of equipment are also employed throughout this process, some of which are manual and others are automated. Any company that wants to improve its production efficiency should examine its raw material handling equipment. Most businesses opt for automated bulk material handling since it is not only more efficient but also saves time and effort.

The correct bulk material handling automation system provider will provide all the necessary equipment, including conveying systems, weighing systems, storage systems and many more. Manufacturers are under constant pressure to finish projects as rapidly as possible while maintaining high quality.

Now you will learn about the major advantages of automated bulk material handling equipment and systems for your process plant.

Process area space optimization

You can make the most of all the space in your process area of the production plant by implementing automation in raw material handling. The system solution prioritizes making the most effective and efficient use of the given area.

Handling of various types of raw materials

You will have multiple raw materials which require handling; thanks to Indpro’s pneumatic conveying systems for raw material handling and some of the standard products such as iTransfer, Bag dump station, Jumbo bag unloading station, DisKCon, and many more which are compatible to handle various raw materials. This is critical if you want your process area inside the plant to flourish with an optimized system solution.

Continuous control of the entire production

Bulk raw material handling automation equipment allows you to have complete control over everything that leaves the production process lines. You will have a record of how much raw material have you consumed for production, how much you need to store, and how much you need to use in the process line to produce finished good products.

Real-time statistics

Through the use of centralized integrated computers and the data being fed into them from the material handling system, you will be able to acquire production figures in real-time basics. Real-time data access is possible because of the plant’s connected technology. Get in touch with Indpro’s experts to know more about the IOT & Industry 4.0 compliant solutions we provide.

Improved labour management & dependency

Raw material handling automation helps with labour management during the manufacturing process in your plant which is one of the most significant advantages. Assigning higher-value activities to your workers that require more human attention and effort. You may also be able to reduce the number of people needed for the project. You can do the task in less time and spend less money on labour and increase efficiency at the same time.

Ensures repeatability of process

It is not a high-skill task to move raw materials from storage areas to production areas or weighing & batching various raw materials to process equipment or to fill finished goods into bags, and many more. However, there are chances of errors propping up due to manual interventions at these stages. Automation systems ensure repeatability of these tasks without errors.

The factory that is more connected

Bulk material handling automation also makes connecting your complete factory a lot easier. Technology allows you to link a large number of materials handling automated systems and handle their tasks more precisely. Once all of the automation is connected, sending and receiving data and handling future actions will be straightforward.

Batch cycle times have improved

Bulk material is not left stranded when no one is available to inspect it. Indpro’s technology does this, allowing the operation to run independently of operators while they focus on their assigned responsibilities. The time it takes to go from one step to the next becomes more predictable, allowing for more accurate cycle time forecasting and customer due date forecasting.

Customer experience enhancement

Bulk material handling automation is advantageous not just during the manufacturing process, but also throughout time. Every business wants to give its consumers the best experience possible. When you use bulk material handling automation, you’re speeding up your production process while also improving the quality of your output. Furthermore, when you save a substantial amount of money using technology, you can offer better prices to your customers which having a more sophisticated manufacturing setup.

Indpro has the technology to build suitable solutions to fit your requirements, allowing your business to expand. Please contact our experts for a consultation on how you can effectively grow your business by automating your production process.