Detergent Powder Manufacturing Process: Spray Drying Method

Detergent Powder Manufacturing Process: Spray Drying Method

Throughout history, people have been engaged in the production of various forms of soap. Today, the distinction between soap and detergent powder is clear but not extensive.

Traditional methods often involved boiling fats and ashes, and even in modern production, which has seen significant enhancements, the fundamental principles remain the same.

Modern powder detergents may be dry and packed with advanced additives, but they are still mainly made from fatty acids and lye.

Throughout this article, we’ll explore the nuances of detergent powder and how it’s manufactured in a manufacturing facility.

What is detergent powder?

Detergent powder is a type of soap in powder form used to clean clothes, sheets, towels, and other fabrics. It works well for both machine washing and hand washing.

Powder detergent is a traditional laundry solution known for its affordability and effective stain-fighting capabilities.

These advantages, among others, contribute to the renewed global popularity of detergent powder. Its cost-effectiveness also positions it as a convenient choice in developing countries.

How detergent powder is produced?

The production of detergent powder typically involves several common methods to create the initial mass or mixture of ingredients. These methods include:

1. Dry Mixing:

In this method, the dry ingredients, such as surfactants, builders, fillers, and additives, are mixed without the addition of water. The dry mixture is blended until it forms a homogeneous mass.

2. Agglomeration process:

It involves combining dry ingredients and then adding a small amount of liquid (often water) to form agglomerates or granules. These granules are dried, after which sharp blades shred the initial mass of dry ingredients to create a fine powder. The detergent produced using this method is easily identifiable by its unique granular appearance.

3.The slurry method:

This method involves ingredients dissolved in water. Spray drying towers propel the slurry into them with the help of pumps. Inside the tower, hot and dry air is introduced, which dehydrates the slurry and results in the formation of beads of dry detergent. This spray drying process is considered one of the most reliable and efficient methods for detergent powder production, making it a strong recommendation in the industry. It ensures consistent drying and the creation of uniform detergent particles.

Ingredients of Detergent Powder:

Surfactants

The surfactants remove stains from the clothes. The most common examples of these compounds include citric acid, cyclodextrin, EDTA and its sodium salts, as well as DTPA (Diethylenetriaminepentaacetic Acid).

Optical Brighteners

Optical brighteners are utilized to improve the color appearance of fabric by creating a “whitening” effect. Among these are anionic diamino stilbenes (DAS), which are derivatives of Distyryl Biphenyl (DSBP).

Fabric Softeners

By adding fabric softener to laundry, wrinkles are reduced, static is reduced, and the laundry is scented with a fresh scent. E.g. Diethyl Ester Dimethyl Ammonium Chloride (DEEDMAC)

Enzymes

These components provide powder detergent with its remarkable cleaning ability, allowing it to target specific types of soils and break them down into smaller molecules. The five classes of enzymes commonly found in detergent powder includes proteases, amylases, lipases, cellulases, and mannanases.

Detergent Builders

Detergent builders are responsible for elevating the alkalinity or pH of the detergent product, thereby enhancing its cleaning effectiveness. E.g. Sodium Tripolyphosphate (STTP), Sodium Carbonate (i.e. soda ash), Sodium Disilicate

Bleaching Agents

It makes clothes to become white or much lighter by chemical process. E.g. Sodium percabonate, Sodium Hypochlorite, Zinc Phthalocyanine Sulphonate, Hydrogen Peroxide

Compounds

There are many compounds used in detergent powder, including lubricants, solvents, etc. These include polyethylene glycols (PEG), polyethylene oxides (PEO), and polyoxyethylenes (POE).

Chelating Agents

Chelating agents are chemical substances that bind with metal ions to form a stable, water-soluble complex. The list includes citric acid, cyclodextrin, EDTA (ethylenediamine tetraacetic acid), and their sodium salts, DTPA (diethylenetriaminepentaacetic acid).

Challenges faced by Detergent Manufacturers

1. Raw material wastage during handling and storage

– One of the key challenges faced by detergent manufacturers is the wastage of raw material during handling and storage which has a major impact on the overall revenue of the company.

2. Price Increase

The major challenge faced by detergent manufacturers is significant inflation in raw material costs. The rising costs are affecting the ability to manage the overall manufacturing costs of the final product, leading to price increases.

3. Dependency on labour

Many processes involved in detergent production requires manual intervention of labour. As the economy progresses, employing labour would get more challenging due to their availability.

Detergent Powder Manufacturing Process

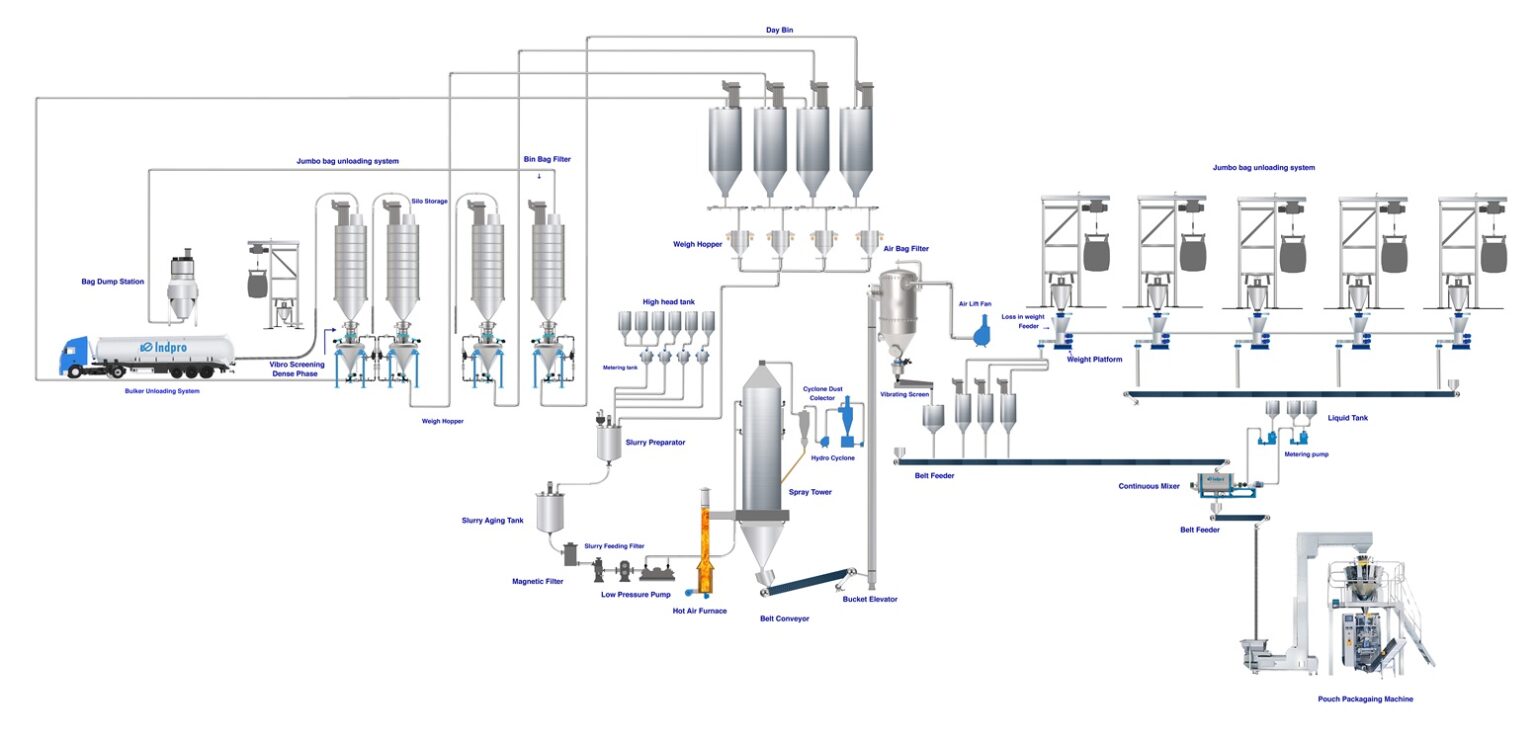

Step 1 - Raw Material Handling and Storage

The production of powder detergent involves two main categories of chemical ingredients: liquids (such as LAS, slurry alcohols, and ethoxylates) and solids (including phosphates, silicates, and carbonates). Most solid chemicals are available in powdered form and are typically packaged in woven bags, as seen with substances like Soda Ash or Sodium Tripolyphosphate (STPP). On the other hand, liquid chemicals like Linear Alkylbenzene Sulfonic Acid (LABSA) or Caustic Soda (Sodium Hydroxide) are often stored in tanks.

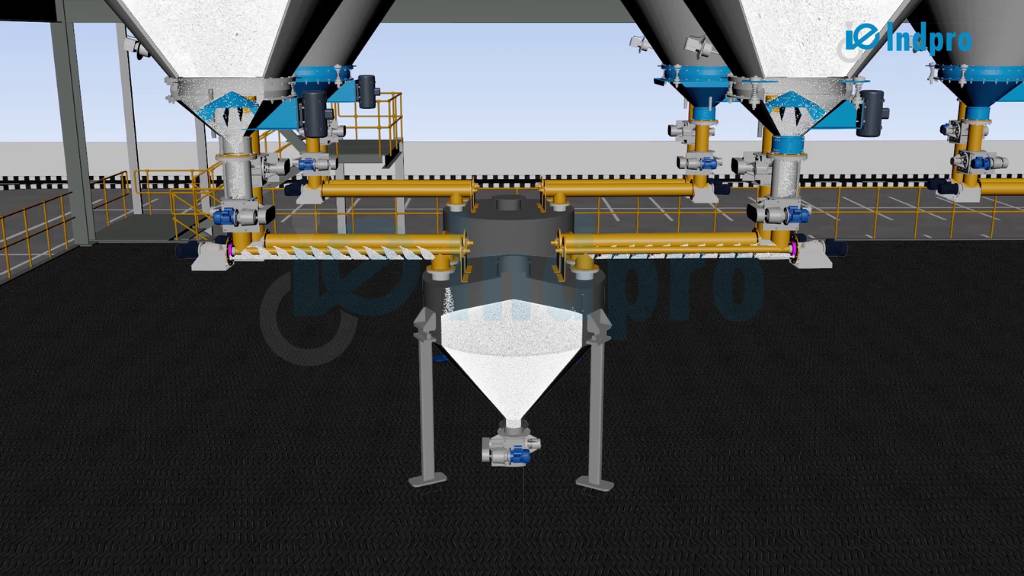

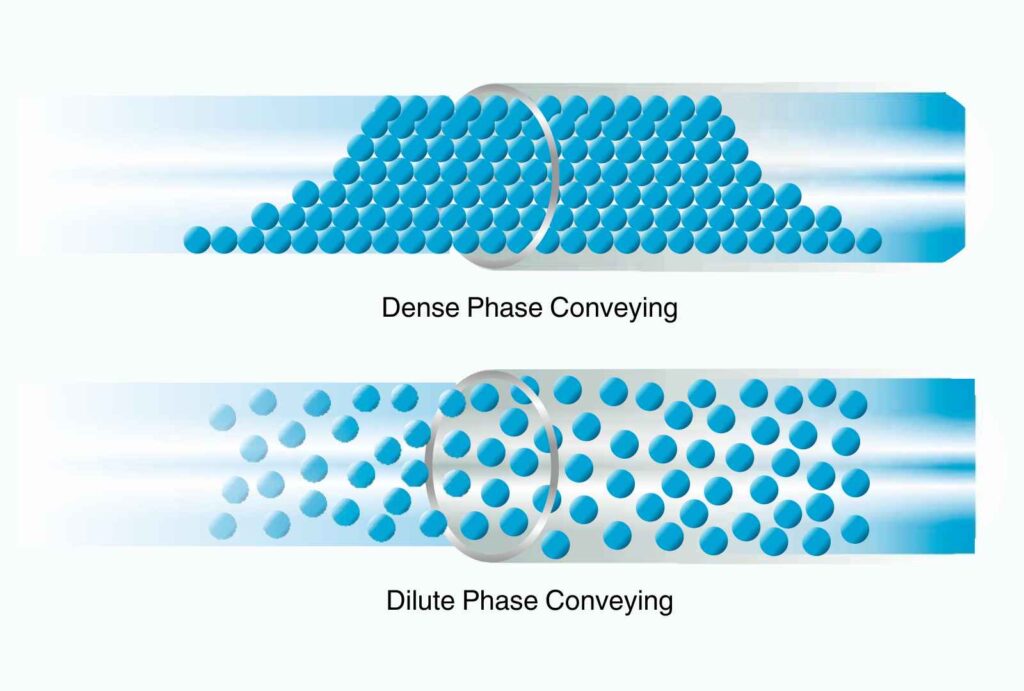

Automation solutions for powder handling such as jumbo bag unloading system, pneumatic conveying system and bulker unloading system can be implemented at raw material receipt & storage section. The powder unloaded can be pneumatically conveyed to storage silo to avoid wastage of raw material during handling and storage. Silo bin activator is an ideal solution which can be integrated with storage silo to avoid silo storage problems such as bridging, ratholing, segregation, incomplete emptying.

Step 2 - Raw materials measuring & dosing

Once the raw material is stored, the production begins with the measurement and dosing of these materials.

Automation solutions such as weighing and batching systems can be used to precisely measure the constituents before mixing. Also, pneumatic conveying system can be used to transfer the raw material in powder form from storage silo to weighing hopper.

Step 3 - Preparation and aging of slurry

The measured raw material, both solid and liquid, is then mixed in mixer, known as slurry preparation tank to form base powder. This involves using a device called a multi-shaft mixer to stir and blend the raw materials with processed water. This mixing process typically lasts for about one hour on average.

Subsequently, the mixed slurry is transferred to an aging tank where it is allowed to “age” for up to half an hour. The aging process can be crucial in achieving the desired properties of the detergent powder.

Step 4 - Spray drying

Following the aging process, the next step in detergent powder production involves the use of pumps to spray the prepared mix to the top of a spray drying tower. Within the tower, specialized nozzles create atomized droplets from the mixture. Simultaneously, a hot air furnace generates hot air, which is directed into the tower to further dehydrate and transform these atomized droplets into dry detergent particles. This process is crucial in producing the fine, dry powder characteristic of detergent.

At the end, the spray-dried granules (particles) fall to the bottom of the tower where they are collected, moved by pneumatic conveying and stored as a base powder in storage silo.

The base powder is a semi-finished product, free of enzymes, fragrances, and colorful speckles. It can be tailored to specific requirements, offered for private labeling, or sold as bulk washing powder.

Step 5 - Air Filtration process

Once all moisture has been evaporated and the hot air cools down, the air needs to be filtered before it is discharged to atmosphere as it contains fine dust particles. The air is passed through dust collector before its discharge.

Step 6 - Post-tower measuring and blending

The post-tower processing plant is responsible for fine-tuning the base powder. This includes adding additives like enzymes, fragrances, colorful speckles, and other ingredients that cannot pass through the spray drying process. These additives are blended with the original mixture to create a customized detergent product.

Automation solutions for this stage include bag dump station, jumbo bag unloading system, weighing and batching system which can be used to precisely measure the constituents before mixing. Also, pneumatic conveying system can be used to transfer the raw material in powder form from storage silo to weighing hopper.

The finished powder is then transferred to the storage section. Automation solutions such as tube chain conveyor can be implemented to transfer the finished detergent powder from continuous mixer to storage silo.

Step 7 - Packaging and Labelling

In the final step of the detergent powder production process, both manual and automatic packing machines are used to load pouches, buckets, and woven bags with the washing powder detergent. This packaging step prepares the product for distribution and sale.

Automation solution such as tube chain conveyor can be implemented at packaging section to transfer the finished detergent powder from storage silo to packing section.