What is Weighing & Batching Hopper?

What is Weighing & Batching Hopper?

The weighing & batching hopper stands as a cornerstone of precision in industrial processes where accuracy and efficiency are paramount. It is an integral part of many manufacturing processes, contributing to the consistency and reliability of the measurement and dispensing of materials. In this blog, we explore weighing & batching hoppers, product dosing methods, and the components of weighing & batching systems to explore what weighing & batching is all about.

Understanding weighing & batching:

Weighing & batching is a method of dispensing materials in predetermined quantities by weight. This precise approach is crucial in industries where the composition and consistency of products are paramount, such as pharmaceuticals, food processing, chemicals, and more. Weighing & batching ensures that the correct proportions of raw materials are used in each batch, leading to consistent product quality.

What is a Weighing & batching Hopper?

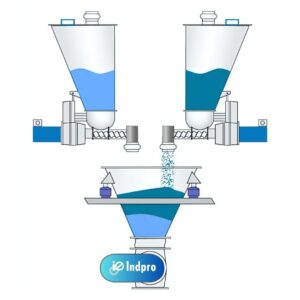

A weighing & batching hopper is at the heart of a weighing & batching system. Based on the weight of the material, this vessel is designed to hold and measure the desired quantity of material. This material can be accurately dosed using the hopper’s load cells or weight measurement devices, which provide real-time feedback to the control system.

Product Dosing Methods

In weighing & batching hoppers, materials are dispensed accurately using various dosing methods. In choosing a dosing method, factors such as material nature, accuracy requirements, and overall manufacturing process need to be considered. Common dosing methods include:

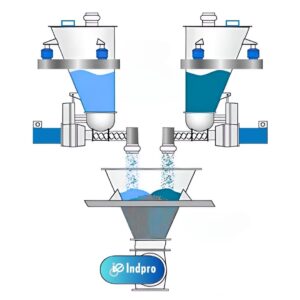

Gain-in-Weight Dosing:

In this method involves filling the weighing & batching hopper with the material gradually until the target weight is reached. Throughout the feeding process, the system monitors the weight gain and adjusts the feeding rate accordingly.

Loss-in-Weight Dosing:

The loss-in-weight method begins with a full hopper, and material is gradually removed until the desired weight is reached. The system monitors the weight loss and adjusts the feed rate accordingly.

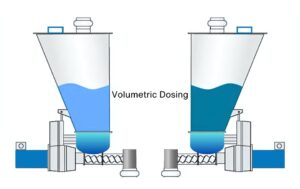

Volumetric Dosing:

Volumetric dosing relies on measuring the volume of material rather than its weight. It is simpler than weight-based dosing, but less accurate than that, and often used in non-critical situations.

Components of a weighing & batching System:

Weighing & batching Hopper:

The central component, the weighing & batching hopper, is designed to securely hold and measure the materials based on weight.

Load Cells:

Load cells are sensors integrated into the weighing & batching hopper, providing real-time weight measurements. These measurements are crucial for accurate dosing.

Feeding Mechanism:

The feeding mechanism, such as a conveyor belt or screw feeder, is responsible for transporting materials into the weighing & batching hopper at the desired rate.

Control System:

The control system oversees the entire weighing & batching process. The microcontroller interprets data from load cells, adjusts the feed rate as required in coarse feed & fine feed, and ensures that the correct quantity of material is dispensed.

Discharge Mechanism:

Once the correct weight is achieved, the discharge mechanism, often a gate or valve, releases the materials from the weighing & batching hopper into the downstream process.

Calibration of Weighing & Batching Hopper

Weigh hopper calibration can be performed using different methods, and two common approaches are static test weigh calibration and material tests. Each method has its advantages and may be chosen based on factors such as the application, the type of material being handled, and the precision required. Here’s an overview of both methods:

1. Static Test Weigh Calibration:

Procedure:

- Zero Calibration: Ensure that the weigh hopper reads zero when empty. This is the initial step to account for any offset or drift in the weighing system.

- Application of Calibration Weights: Apply known calibration weights to the weigh hopper. These weights should cover the expected range of loads the hopper will handle.

- Comparison: Compare the actual weight applied to the weigh hopper with the recorded weight displayed by the weighing system.

- Adjustments: Make any necessary adjustments to the calibration settings based on the comparison results.

Advantages:

- Static test weigh calibration provides a straightforward and direct method to calibrate the weighing system.

- It is suitable for applications where the material properties or handling characteristics are not critical to the calibration process.

Considerations:

This method assumes that the weighing system behaves consistently under static conditions, and the material properties do not significantly affect the calibration.

2. Material Tests:

Procedure:

- Zero Calibration: Zero the weigh hopper when empty.

- Material Loading: Load the weigh hopper with the actual material it will handle during normal operations.

- Weighing Process: The process of weighing the material should be recorded as the material is being loaded and discharged. This involves simulating the actual operating conditions.

- Comparison and Adjustments: Compare the recorded weights with the expected values. Make adjustments to the calibration settings based on the comparison.

Advantages:

- Material tests take into account the specific characteristics of the material being handled, including factors such as flowability, density, and handling dynamics.

- This method provides a more realistic representation of the weighing system's performance under actual operating conditions.

Considerations:

- Material tests may be more time-consuming and may require careful control of the material flow to ensure accurate results.

- The material used for testing should be representative of the materials the system will handle in normal operations.

Advantages of Weighing & batching:

- Precision: Weighing & batching ensures precise measurement, minimizing variations in material composition and contributing to consistent product quality.

- Efficiency: By accurately dispensing materials, weighing & batching reduces waste and ensures that the right amount of raw materials is used in each batch.

- Flexibility: Weighing & batching systems can be adapted to a wide range of materials and manufacturing processes, making them versatile in various industries.

- Quality Control: The accuracy of weighing & batching contributes to stringent quality control measures, meeting regulatory standards and customer expectations.

In the symphony of industrial processes, the weighing & batching hopper plays a virtuoso role, ensuring harmony and precision. From pharmaceutical formulations to food recipes, the reliability and accuracy of weighing & batching systems are indispensable. As industries continue to prioritize consistency and efficiency, the weighing & batching hopper stands as a testament to the art and science of precision manufacturing, shaping the landscape of diverse industrial sectors.