Key Factors to Consider for Efficient Pneumatic Conveying System Design

Key Factors to Consider for Efficient Pneumatic Conveying System Design

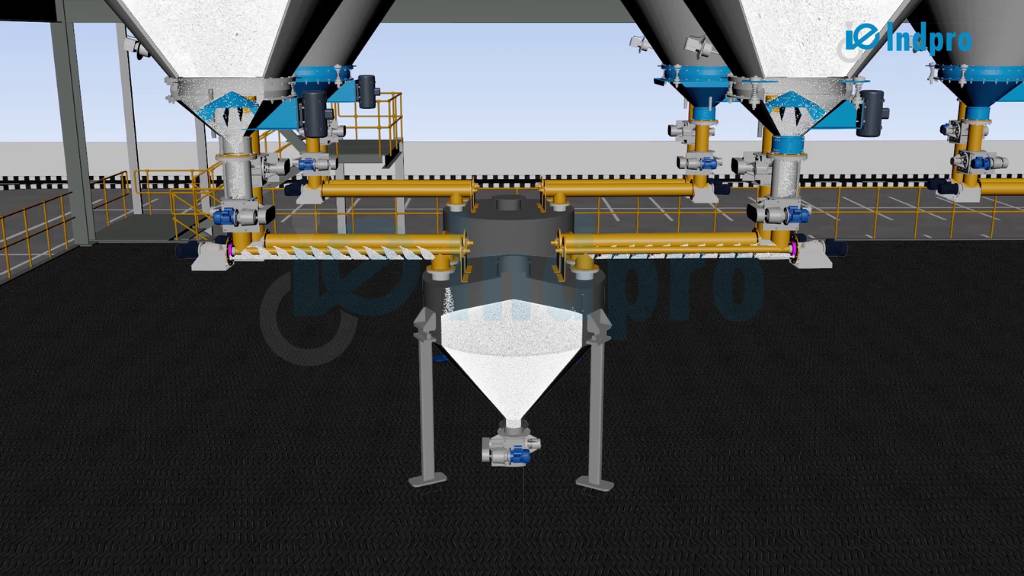

A pneumatic conveying system is a method of conveying bulk materials, such as powders or granules, from one place to another through a pipeline using a gas, usually air, as the conveying medium. Pneumatic conveying is preferred for its ability to move materials over long distances, minimize material degradation, and provide flexibility in the layout of the system. Pneumatic conveying systems are employed in a variety of industries, including food & spices, pharmaceuticals, plastics & polymer, chemicals & petrochemical, minerals, and more.

Understanding the functioning of pneumatic conveying systems is crucial for conveyor manufacturers. Consideration of various factors, including the specific process requirements and the nature of materials being handled, is essential. This knowledge allows manufacturers to develop customized plans with the right components, ensuring the delivery of effective solutions tailored to the customer’s specific needs.

Factors to be considered for Pneumatic Conveying System Design

1. Conveying Distance

The distance bulk solids must travel is a critical consideration when designing a bulk solids transportation system. As the conveying distance increases, frictional losses cause the material to move through the pipes at higher speeds, requiring more energy. Consequently, longer conveying distances demand greater energy input.

The routing of the conveying pipe, including horizontal sections, vertical sections, and bends, contributes to specific energy requirements. Understanding the conveying distances, both horizontal and vertical, as well as the number of bends, is an essential initial step in the design process. This information helps in optimizing the system for efficiency and energy consumption.

2. Pick-up Location and Material Container

In many cases, bulk materials are stored in various containers such as silos, jumbo bags, small bags. During the conveying process, the conveying system must pick up the products from these storage points and transport them to the designated location as efficiently as possible.

Each pick-up station and the type of product will have specific design features that influence the conveying process. For example, a flour storage silo discharging into a conveying line might require an airlock, whereas a plastic pellet storage silo used for vacuum conveying may not.

Whether it’s a storage silo, bulk bag discharger, bag dump station, the interaction with the conveying system specific to the product is a critical consideration for a system designer. This ensures that the conveying process is tailored to the unique characteristics and requirements of each material and storage container.

3. Product Characteristics

It is very important to know product characteristics while designing pneumatic conveying system.

Product Classification:

Food and Dairy products require materials compliant with food safety regulations, FDA/USDA approvals, and adherence to GMP practices. Chemical products necessitate corrosion-resistant materials and compatibility with specific chemical properties to ensure product integrity and safety. Understanding these unique requirements is crucial in the selection process for each industry.

Moisture Content:

Handling high-moisture products requires careful consideration and testing before selecting conveying systems. For hygroscopic products, which may absorb moisture from the conveying air, special attention and testing is essential. Additionally, creating an environment with controlled humidity, such as an air-conditioned room or dehumidification of conveying air, may be necessary to prevent moisture-related issues during the conveying process.

Abrasive Products:

Abrasive products can significantly contribute to wear and tear on conveyance lines. In such cases, it is often advisable to use special wear-resistant conveying lines, elbows and other rotating parts of the system. These components are designed to withstand the abrasive nature of certain materials, extending the lifespan of the conveying system and reducing the need for frequent maintenance and replacements.

Toxicity:

It is important to know whether the material to be conveyed has any environmental and emission requirements from statutory bodies like OSHA or local authorities.

Particle Size:

Understanding and categorizing materials based on their particle size is fundamental for selecting the appropriate conveying system and ensuring efficient material handling.

- Powders: Generally, powders are particles smaller than 1000 microns or 1mm in size.

- Granules: Granules typically refer to products with particle sizes larger than 1mm.

- Pellets/Grains: These are even larger particles, significantly exceeding the 1mm size.

- Special Attention for Larger Particles: Particle sizes greater than 10 mm (<1/2″ size) may require special attention or testing in the design process.

- Mesh Size: In some cases, particle size is expressed in mesh size (e.g., 10 mesh, 100 mesh)

Bulk Density of Material:

Bulk density refers to the mass of a bulk material per unit volume. It is a measure of how much mass is contained in a given volume of material. The bulk density of a substance is usually expressed in units such as kilograms per cubic meter (kg/m³) or pounds per cubic foot (lb/ft³), depending on the unit system being used.

Formula for calculating bulk density is,

Bulk Density = Mass of Material/Volume of Material

For example, if you have a certain quantity of material with a mass of 500 kilograms and the volume it occupies is 2 cubic meters, then, Bulk Density = 500/2 = 250 kg/m³

4. Material of construction

Selecting the right materials ensures compliance with industry standards, prevents contamination, and enhances the system’s durability and cleanliness. Mostly stainless-steel material is used for pneumatic conveying systems. Stainless steel grades used are SS304, SS304L, SS316, SS316L. FDA-approved plastics are used for pneumatic conveying system for food products. For certain applications, it is also possible to go with special type of polymer coating on the steel surface for advanced corrosion resistance.

5. Process specification - Batch or Continuous Process

Understanding the nature of the process, whether it involves discrete batches or continuous material flow, is essential for designing a pneumatic conveying system that meets the specific requirements and challenges of the application.

6. Conveying Rate

The desired rate at which the material needs to be conveyed influences the sizing and capacity of the pneumatic conveying system components. Calculating conveying rates requires a clear understanding of the amount of material to be transported per unit of time.

For calculating the conveying rate:

- Determine the quantity of material to be transported per hour, specifying whether it’s in pounds or kilos.

- Clearly define whether the process is batch or continuous.

7. Pipeline Design

- Pipeline Diameter: The diameter of the pipeline affects the material-to-air ratio and pressure drop.

- Pipeline Layout: Consider the layout of the pipeline, including bends, elbows, and vertical or horizontal sections.

8. Material Feeding Mechanism

Choose an appropriate material feeder (e.g., rotary valve, screw feeder) based on the material’s flow characteristics and the desired feeding rate.

9. Material Segregation

Address any concerns related to material segregation during conveying, especially for materials with varying particle sizes.

10. System Flexibility

Design the system to be flexible to accommodate changes in material properties, production rates, and future process requirements.

11. Environmental Considerations

Consider environmental factors like temperature and humidity, which can impact both the material being conveyed and the performance of the conveying system.

12. Maintenance and Accessibility

Design the system with accessibility in mind, ensuring it can be easily disassembled for maintenance and cleaning. Prioritize user-friendly features to simplify the cleaning process.

13. Safety

Consider safety features, such as pressure relief devices and monitoring systems, to ensure safe operation.

14. Economic Considerations

Evaluate the overall cost of the system, including initial capital costs, operating costs, and maintenance costs.