Dedusting System for Plastic Pellets

Dedusting System for Plastic Pellets

In the plastic manufacturing industry, maintaining product quality and manufacturing efficiency is paramount. One critical aspect of this is the management of dust and streamers, which are commonly generated during the pneumatic conveying process or during mixing and blending operations. To address this, an effective plastic pellet dedusting system is essential.

Sources of Dust and Streamers

Dust and streamers in the plastic industry primarily arise from two types of pneumatic conveying processes:

This method involves material transfer at high speeds, resulting in increased dust and streamer production. The swift motion induces abrasion and friction, degrading pellets into fine particles and streamers.

Although generating less dust and streamers due to lower velocities, this method still produces fine particles that require removal to ensure high product quality.

During the mixing and blending of plastic pellets, mechanical agitation can cause friction and impact, resulting in the generation of dust and streamers. The interaction of materials in these processes often breaks down the pellets, contributing to dust formation.

Impact of Dust and Streamers

The presence of dust and streamers can trigger various adverse effects in the plastic manufacturing process:

Surface Blurring

Vaporized dust particles can blur the surface of final plastic products, impacting their appearance and aesthetic appeal.

Increased Scrap Rates

Fine particles may burn within molds, leading to heightened scrap rates and reduced manufacturing efficiency.

Wire Insulation Defects

Dust can provoke defects in wire insulation, jeopardizing the safety and functionality of electrical components.

Gel Formation in Films

Dust presence may instigate gel formation within plastic films, influencing clarity and uniformity.

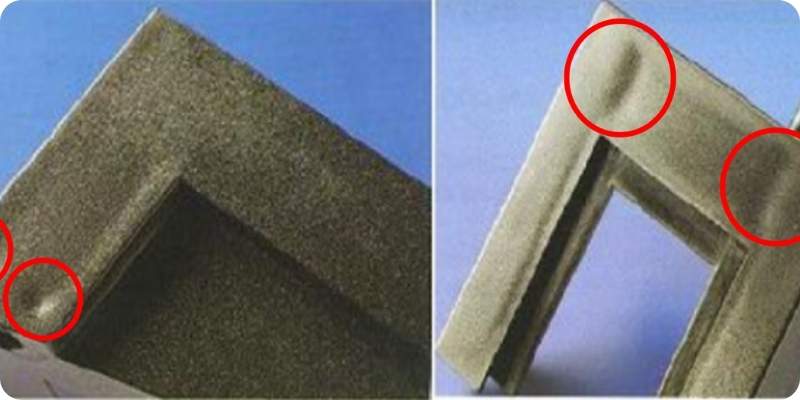

Sink Marks on Parts

Dust accumulation in molds can result in unsightly sink marks on plastic parts, affecting their structural integrity and visual appeal.

How Dedusting system for plastic industry works:

The New Patented technology of Plastic Pellet Dedusting system PelletPurge® is specially designed to clean plastic pellets by removing dust and streamers, setting a new benchmark in plastic pellet manufacturing. Positioned strategically beneath storage silos before plastic processing or packing, it effectively eliminates impurities, enhancing the overall product quality. Embrace this cutting-edge solution with us and take your manufacturing processes to new levels with PelletPurge®!

Applications for the Plastics Processing Industry

- Cleaning plastic pellets at the machine feed throat before Injection molding or extruder to ensure optimal optical clarity.

- It can also clean pellets as they are fed into central surge bins or day bins, feeding multiple machines or dryers.

- Whether at a cleaning station in a Railcar or truck unload system, drying process, regrinds operation, packaging area.

- Even recycling plants, this system eliminates dust before loading into storage silos or processing equipment.

- You can install PelletPurge® system under silos, loading hoppers of packing machines, extruder feed hoppers, or even on injection molding machines. Experience the efficiency and quality improvements that this system brings to the plastic industry!