How Dense Phase Conveying Protects Silicon Powder Integrity in Battery Production?

How Dense Phase Conveying Protects Silicon Powder Integrity in Battery Production?

The global push toward electric mobility and renewable energy storage has put battery technology in the spotlight like never before. Among the many materials fueling this revolution, silicon powder has quickly emerged as a game-changer — promising higher energy density and improved performance over traditional graphite anodes. Yet handling silicon powder is not without challenges. Its ultra-fine particles are prone to degradation, segregation, and pose critical safety risks.

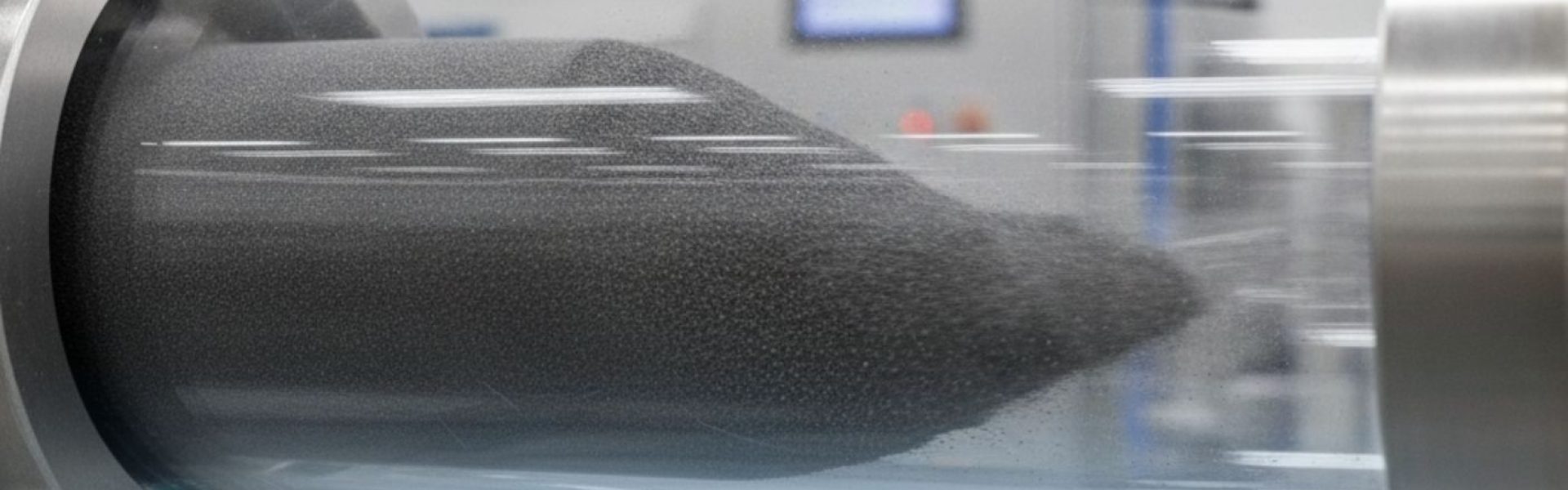

This is where dense phase pneumatic conveying shines protecting the integrity of silicon powder during transport while ensuring safety, efficiency, and compliance.

In this blog, we will explore what silicon powder is, its key properties and applications in battery manufacturing, and how dense phase pneumatic conveying through low-velocity, high-pressure transport plays a vital role in preserving particle integrity, preventing degradation, ensuring uniform particle size, and enabling safe, ATEX-compliant handling of this sensitive material.

What Is Silicon Powder?

Silicon powder consists of extremely small particles of elemental silicon a metalloid that sits between metals and non-metals on the periodic table. In its powdered form, silicon becomes a versatile feedstock used in a range of high-tech applications.

Silicon powder is produced via specialized processes such as reduction of silicon tetrachloride or metallurgical silicon grinding to achieve controlled particle sizes tailored to specific end-use requirements.

Key Properties of Silicon Powder

Silicon powder presents a unique combination of physical and chemical properties that make it highly valuable and equally challenging to handle:

- Ultra-fine particle size: Typically, in the micrometer (µm) or submicron range.

- High surface area: Enhances reactivity and electrochemical performance.

- Brittle nature: Susceptible to fracture and particle size change under mechanical stress.

- Low bulk density: Leads to aeration and fluidization challenges.

- High purity: Battery-grade silicon powder requires purity levels often exceeding 99%.

- Oxidation tendency: Can react with oxygen, particularly at elevated temperatures.

Applications of Silicon Powder

1. Battery Production: In lithium-ion batteries, silicon powder is increasingly blended into the anode to significantly improve energy density sometimes by 10x compared to conventional graphite. Its ability to pair with lithium makes it ideal for next-generation battery designs.

2. Electronics & Semiconductors: Used in the manufacture of electronic components, microchips, and photovoltaic cells due to its semiconducting properties.

3. Additive Manufacturing: In powder-based metal 3D printing processes, silicon powders are used to produce lightweight, high-performance parts.

4. Metallurgical and Chemical Industries: As an alloying agent and precursor in the manufacture of silicones and other specialty chemicals.

Challenges in Handling Silicon Powder

- Particle breakage and degradation: High-velocity conveying systems can damage the fragile particles, cause fines generation, and result in particle size distribution changes reducing functional performance.

- Segregation: Differences in particle size and density can cause separation during transport, leading to inconsistent batches.

- Dust generation: Fine powders easily form airborne dust raising health, explosion, and environmental concerns.

- Safety hazards: Fine silicon powder can be combustible and potentially explosive under the right conditions.

- Regulatory compliance: Handling must meet strict standards such as ATEX (for explosive atmospheres) and local workplace safety regulations.

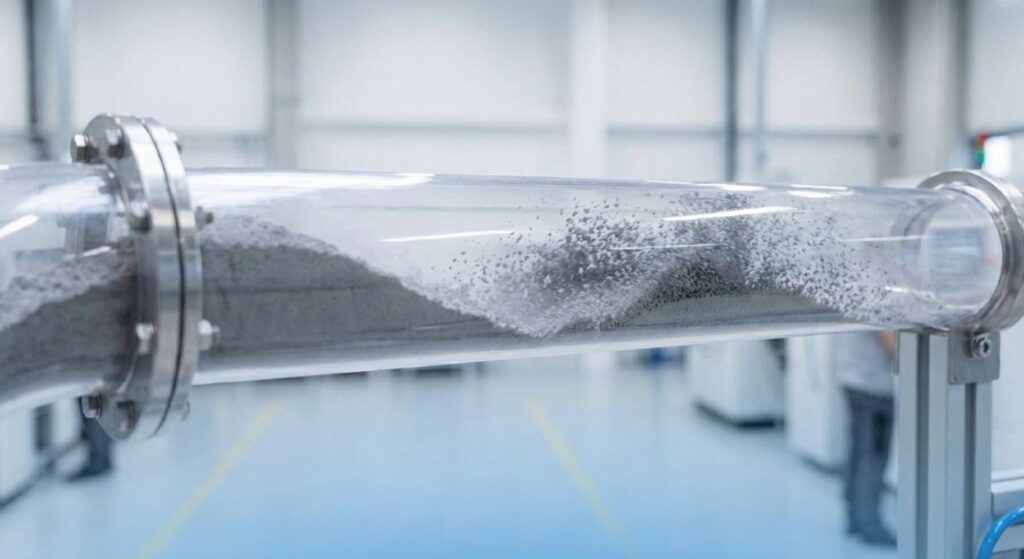

Why Dense Phase Pneumatic Conveying Is Ideal for Silicon Powder

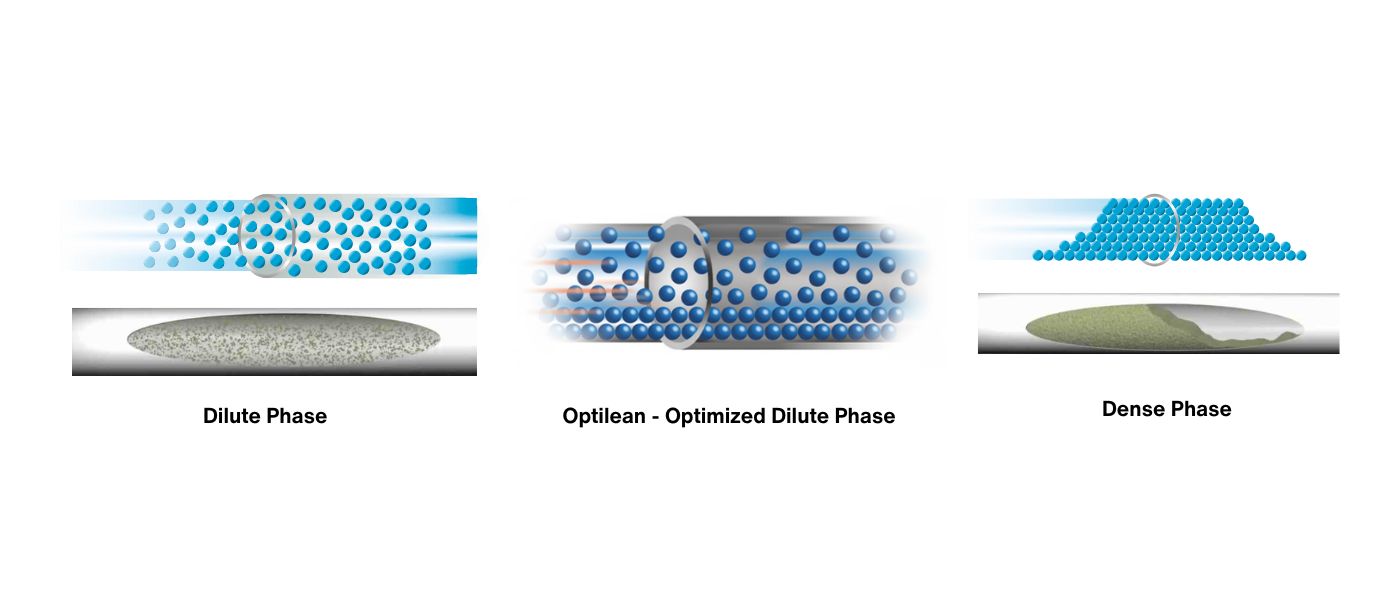

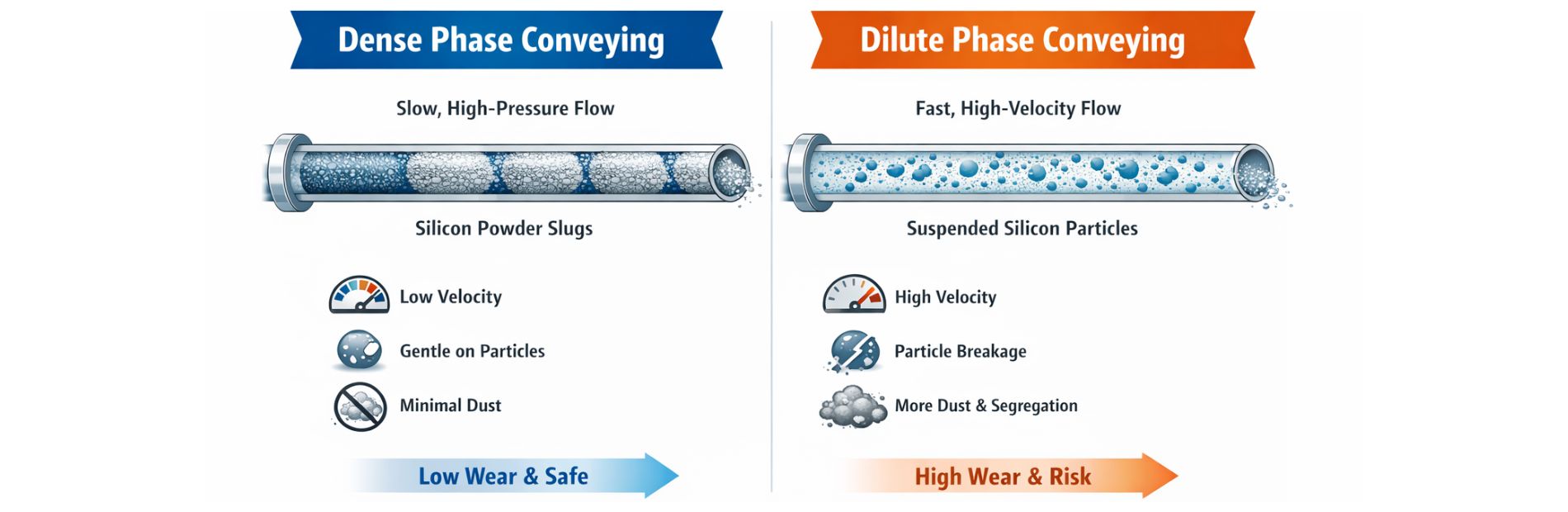

Silicon powder is extremely fine, fragile, and sensitive to mechanical stress. Choosing the right conveying method is critical to protect material quality and ensure safe handling. The table below explains why dense phase pneumatic conveying is better suited than conventional dilute phase systems for battery-grade silicon powder.

| Parameter | Dense Phase Conveying (Low Velocity) | Dilute Phase Conveying (High Velocity) |

|---|---|---|

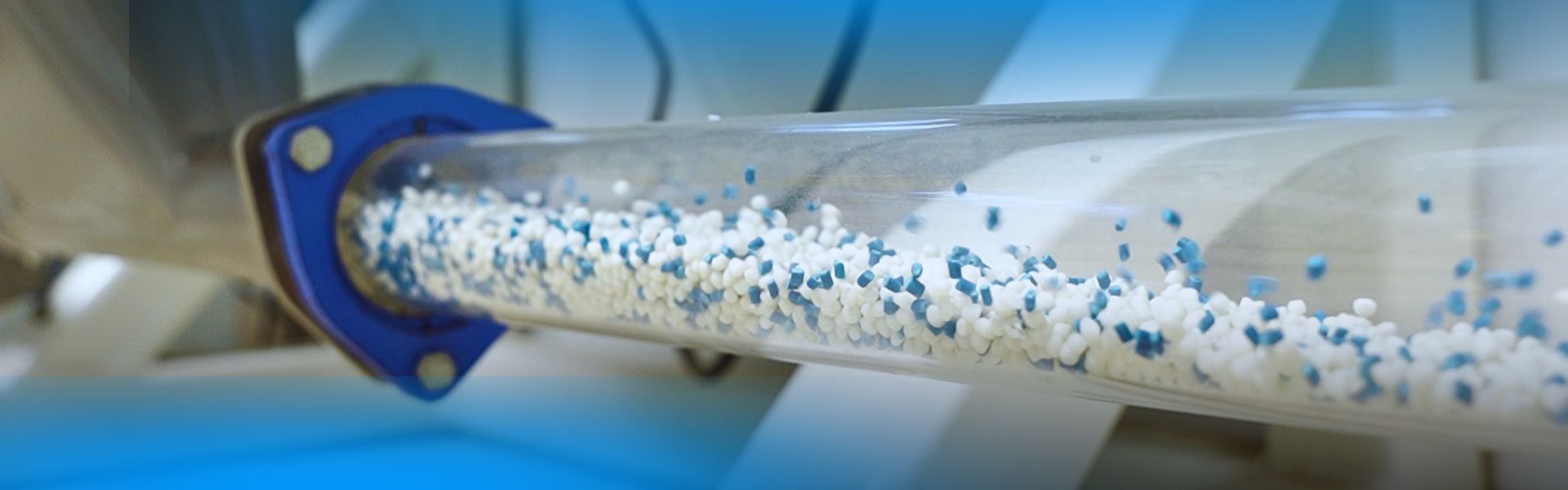

| Conveying velocity | Low air speed moves material in plugs or slugs | High air speed keeps material suspended |

| Impact on silicon particles | Gentle movement preserves particle shape and size | High particle collision causes breakage and fines generation |

| Particle size consistency | Maintains uniform particle size distribution | Particle degradation leads to inconsistent PSD |

| Dust generation | Minimal dust due to low turbulence | High turbulence creates airborne dust |

| Material segregation | Uniform flow minimizes segregation | Higher chance of separation during transfer |

| Wear on pipelines | Reduced pipeline wear | Increased erosion due to high-speed particles |

| Energy consumption | Lower overall air usage | Higher due to continuous airflow |

| Explosion risk | Reduced risk because of low dust formation | Higher due to dust clouds and static build-up |

| Suitability for silicon powder | Highly suitable for sensitive, fine powders | Not recommended for battery-grade powders |

Parameter | Dense Phase Conveying (Low Velocity) | Dilute Phase Conveying (High Velocity) |

Conveying velocity | Low air speed moves material in plugs or slugs | High air speed keeps material suspended |

Impact on silicon particles | Gentle movement preserves particle shape and size | High particle collision causes breakage and fines generation |

Particle size consistency | Maintains uniform particle size distribution | Particle degradation leads to inconsistent PSD |

Dust generation | Minimal dust due to low turbulence | High turbulence creates airborne dust |

Material segregation | Uniform flow minimizes segregation | Higher chance of separation during transfer |

Wear on pipelines | Reduced pipeline wear | Increased erosion due to high-speed particles |

Energy consumption | Lower overall air usage | Higher due to continuous airflow |

Explosion risk | Reduced risk because of low dust formation | Higher due to dust clouds and static build-up |

Suitability for silicon powder | Highly suitable for sensitive, fine powders | Not recommended for battery-grade powders |

How Dense Phase Conveying Protects Material Integrity

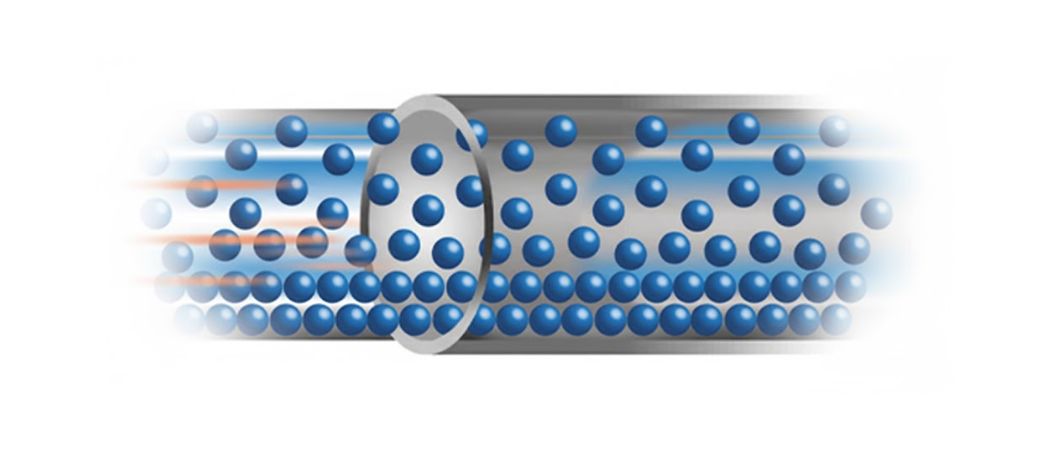

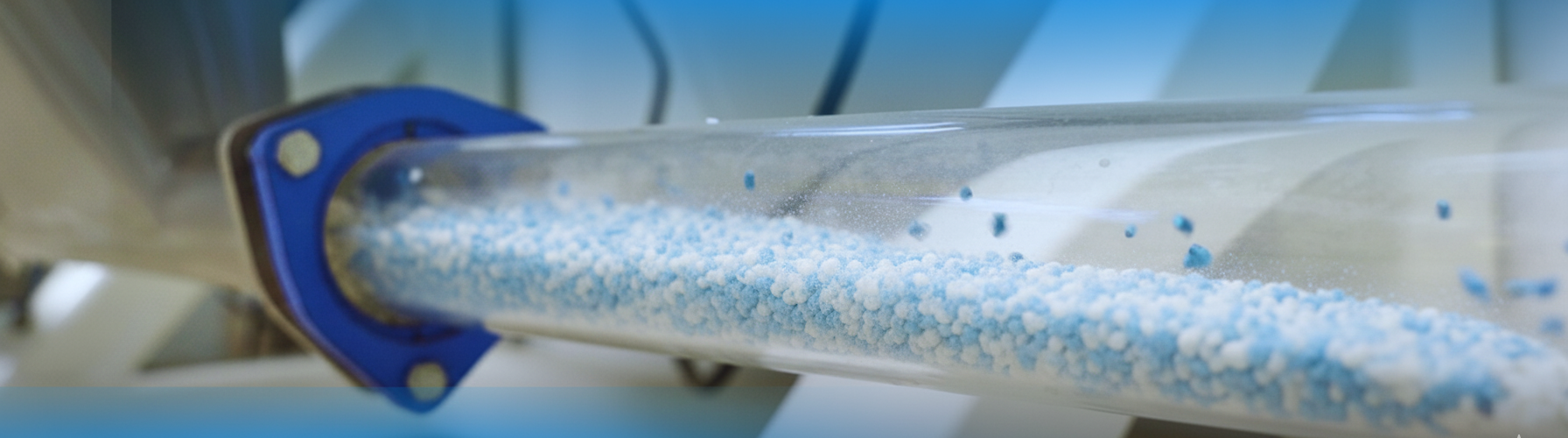

1. Low-Velocity, High-Pressure Movement:

- Reduces impact and collisions between particles

- Minimizes particle fracture or attrition

- Preserves narrow particle size distribution

Maintaining a uniform particle size is crucial for battery performance too many fines or large agglomerates can reduce electrode consistency and cycle life.

2. Dust Control and Environmental Safety:

- Closed-loop conveying preventing powder escape

- Lower airflow reduces dust entrainment

- Integrated filters and cyclone separators collect residual particulates

- Improved housekeeping and environmental compliance

3. Explosion Risk and ATEX Compliance:

- Reducing Turbulence – Low-velocity flow means fewer chances of static discharge and dust clouds the primary drivers of explosive atmospheres.

- Minimizing Dust Clouds – Less entrained dust reduces the likelihood of combustible dust layers forming on surfaces.

- System Design for Safety – Conveying systems can be engineered to comply with ATEX Directive (2014/34/EU) or similar local safety standards, which mandate:

Meeting ATEX requirements protects equipment and personnel – and ensures compliance with global manufacturing standards.

Conclusion

In the high-stakes world of battery production, material integrity and safety cannot be compromised. Silicon powder plays a pivotal role in the next generation of high-performance batteries but only if its properties are preserved during handling and transfer.

Dense phase pneumatic conveying systems offer a powerful solution delivering ultra-fine powders with minimal degradation, reduced dust, improved safety, and regulatory compliance. By embracing low-velocity, controlled transport environments, manufacturers can protect product quality, safeguard workers, and support the cutting edge of energy storage innovation.