Biscuit manufacturing process

Biscuit manufacturing process

The term “biscuit” finds its origins in the Latin phrase “bis cotus,” translating to “twice baked.” This culinary concept traces its roots back to the time of the Romans. Nonetheless, the biscuits we recognize today started to evolve during the era of the Middle Ages.

In the 1800s, spurred by the Industrial Revolution, the era of mass-producing cakes, biscuits, and jellies was ushered in. It was during this transformative period that numerous novel biscuit varieties came into existence.

On the global stage, India holds the distinction of being the third-largest biscuit producer, trailing behind only the United States and China. This status is driven by factors such as increased consumer income, a preference for premium biscuits, expanded production capacity, growing health awareness, product innovation, and appealing packaging.

As demand continues to surge, it becomes imperative for production to keep pace accordingly. To enhance and refine the biscuit production process, the implementation of plant automation is crucial. Tasks such as raw material handling, bulk storage, cleaning & sieving, mixing, batch preparation, and packaging are automated within biscuit processing. This automation culminates in the production of a top-tier, high-quality finished product.

Indpro specializes in automated bulk material handling systems, catering to the needs of biscuit manufacturers. Our solutions seamlessly manage raw materials handling, starting with the efficient transfer of materials from bulk containers or bulkers into various storage silos.

Both external and internal silos play vital roles in the production process, serving as indispensable components. The automation solutions include handling of 25 to 50-kg bags and even upto 1000 kg jumbo bags which ensure a smooth transition from handling powders inside the bags into the production line using utmost automation while eliminating dusting & maintaining expected hygiene standards.

Additionally, precise weighing systems for ingredients and minor components ensure accuracy in the production process. This comprehensive suite of offerings plays a vital role in optimizing biscuit manufacturing and other related industries, enhancing efficiency, and maintaining product quality.

Materials used for Biscuit Manufacturing are –

Flour

Typically, wheat flour is the primary ingredient in biscuit manufacturing, although other flours like rice or corn may also be used.

Sugar

Sugar provides sweetness and aids in browning.

Leavening Agents

Baking powder and/or baking soda, play a crucial role in causing biscuits to rise, resulting in their characteristic light and fluffy texture.

Liquid

Water or milk is added to bind the ingredients together.

Flavorings

Flavorings like vanilla, chocolate chips, nuts, and spices are often added for taste.

Fats

Fats such as butter, margarine, or vegetable oils contribute to the texture and flavor of biscuits.

Challenges faced by the Biscuit Manufacturing Industry:

Mixing of Foreign Matter:

In the biscuit production process and throughout the raw material supply chain, the inadvertent inclusion of foreign objects like operators’ hair, plastic bristles, packaging materials, sealing threads, needles, and the like, poses a risk of compromising product quality and safety.

Excessive sulfur dioxide:

Excess sulfur dioxide content found in biscuits primarily stems from the breakdown of the dough modifier, sodium metabisulfite. In the biscuit manufacturing process, food companies may occasionally incorporate excessive quantities of sodium metabisulfite to enhance dough extensibility and plasticity, inadvertently leading to elevated sulfur dioxide levels.

Misuse of additives:

Due to fierce market competition, some biscuit manufacturers use cost-cutting additives to improve taste. These additives, when misused, can be harmful to consumers, often going unnoticed.

Cost Escalation

The biscuit industry’s growth is currently hindered by significant inflation in raw material and packaging costs. The cost escalation is impacting to control the final product manufacturing cost ultimately seeing hike in prices.

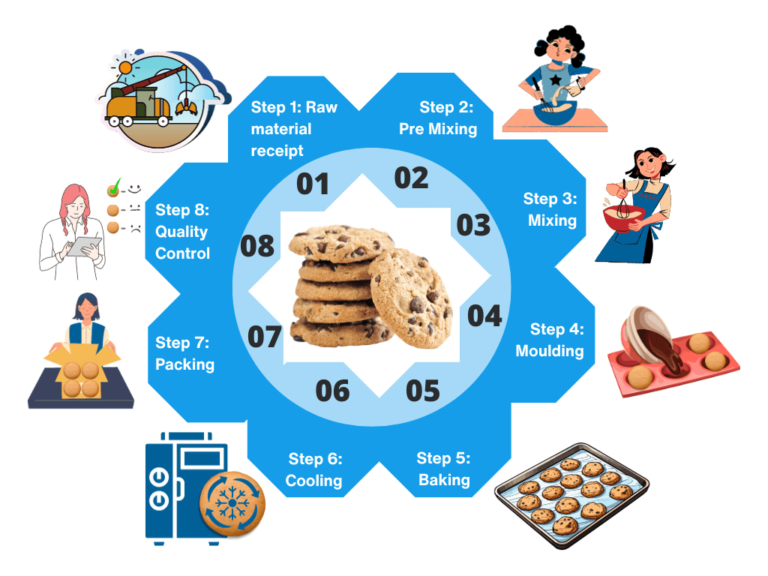

Steps followed by the current industries for manufacturing biscuits:

Step 1: Raw material receipt:

In the realm of ingredient management, a well-structured warehouse is the hub for gathering and storing various ingredients, packaged in diverse formats such as bags (25 to 50 kg), jumbo bags (500 to 1000 kg), drums (50 kg), and even bulker shipments. Preserving ingredient quality during transportation is critical, requiring a well-orchestrated supply chain.

Automation solutions include Raw Material Handling solutions, including a Manual Bag Dump Station, Bag Lifter & Tilter, Jumbo Bag Unloading System, Bulker Unloading System, Automatic Bag Slitting Machine, Storage Silos, and Pneumatic Conveying System. These solutions streamline ingredient logistics, ensuring efficient and reliable transport, and supporting various industries’ smooth operations.

Step 2: Pre-Mixing:

In the biscuit-making process, the dry ingredients, including wheat flour, sugar, leavening agents, Skimmed Milk Powder, and Malt extract, along with fats, are first combined and mixed until they resemble coarse crumbs.

Here is where automation systems play a crucial role, offering a range of specialized equipment and systems to facilitate this mixing process. These solutions include Specialized Blenders and Weighing & Batching Systems. These solutions ensure a seamless and efficient transition from the initial mixing of dry ingredients to the subsequent stages of biscuit production, contributing to the consistency and quality of the final product.

Step 3: Mixing:

As the biscuit-making process advances, the dough begins to take shape, and this is where the liquid ingredients, along with sugar, are carefully introduced to achieve the desired consistency in the mixture. For biscuits like short dough varieties, a lighter mixing is employed to maintain crispiness and fluffiness.

Step 4: Moulding:

During this crucial stage, the biscuit’s shape is determined, with options ranging from round to various intricate designs. This process divides the dough into desired portions and involves a knife, a forcing roller, and precise control in multiple directions.

Step 5: Baking:

Biscuits are baked in ovens at a specific temperature and time, which varies depending on the type of biscuit being produced. The heat causes the leavening agents to create gas, making the biscuits rise and become crispy.

After baking, a batch or batches of biscuits are checked for their texture, color, cooking level, and height. A meticulous inspection process ensures that they meet the required specifications.

Step 6: Cooling:

After baking, biscuits are cooled on wire racks to room temperature. The biscuits pass through a cooling tunnel, where they are cooled to the desired hardness, preparing them for packaging.

Step 7: Packing:

Once cooled, biscuits are packaged in various ways, including boxes, bags, or individual wrappers. Packaging often includes branding and labeling for marketing purposes.

Step 8: Quality Control:

Biscuit manufacturers implement strict quality control measures to ensure consistency in taste, texture, and appearance. Samples are regularly tested for taste, texture, and shelf life.