Air Pollution Control – A need of the hour

Air Pollution Control – A need of the hour

World Health Organization (WHO), states “Solid dust, from below 1 mm, to a minimum of 100 mm, are often transmitted or may be transmitted by air, depending upon the quantity. They are usually released into the air by natural forces including pollens in soil, sandstorms, and volcanic ashes “Their structure, physical characteristics, and environmental factors”. Manual processes, i.e. grinding, cutting, and crushing also can generate these. Small in size, this often makes them invisible to the eye, making them difficult to control only by human effort. Dust consists of small particles in its most elementary form which floats within the atmosphere. Dust can mix with anything from pollen, to skin cells, to harmful pollution particles, depending on the environment or industry being worked in. Dust are often produced from a variety of sources.

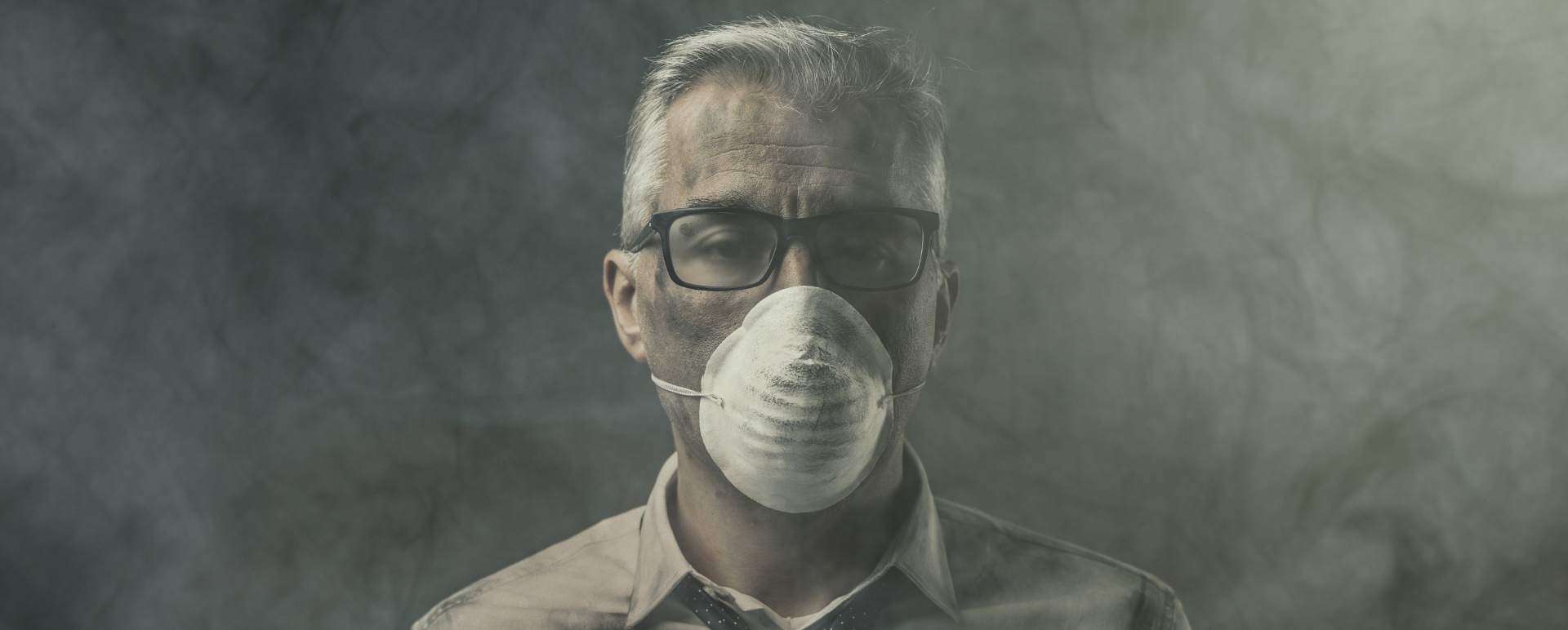

This kind of dust is generated while conveying pharmaceutical/chemical powders from one place to another for their processing in plants. This will be very harmful as sometimes these powders are hazardous if inhaled. Even the utilization of masks might not be sufficient to arrest them. So dust collectors are necessary for such applications. These dust collectors in first place refrain from releasing such particles within the atmosphere by arresting them in the process itself.

Fiberglass, or glass wool, consists of glass filaments combined with yarn and woven into a cloth. Although there is inadequate data, many suspect that fiberglass can cause respiratory diseases when worn down and turned into an airborne material. Wearing a mask when working with fiberglass or other manufactured plastics is strongly suggested as a precautionary measure.

Metal dust usually forms by grinding metal during any metal manufacturing process. Workers subjected to metal dust can suffer from lung and throat irritation. Other sorts of metal dust are often highly poisonous, particularly if the metal consists of heavy metals such as cobalt, lead, or nickel. If dealing with the metal it is necessary to wear any form of a respirator to avoid injury to the lungs.

The silica dust is airborne while dealing with concrete and might be harmful. Exposure to silica dust may result in a disease caused by inhaling an excessive amount of the silica found in dust. Such small particles may cause the lungs to thicken or scarring of lungs, and eventually trigger lung cancer.

Wood dust is additionally referred to as sawdust, as a result of wood manipulation. Whether it’s by sanding, scraping, digging, or shaving, small wood particles are emitted into the soil, creating a coating of dust until deposited. Wood dust are often hazardous when inhaled. It may cause allergic reactions, problems with the oral mucous membrane, or cancer, although the extent of these risks has not been fully identified.

Air pollution control equipment is a vital component of industrial processes that cannot be neglected. Name any industry, and you will realize the extent of harmful stuff it sends into the environment through its processes. Petroleum, energy production, coal and metal mining, chemical, and waste management industries are a few of the many players that have played a considerable role in polluting the environment. Every industrial procedure – including sourcing of raw materials, manufacturing of the final product, maintenance of the site and machinery, and transporting of the product to different locations – results in some kind of pollution. The burning of fossil fuel releases volatile hydrocarbons, burning wood and coal as fuel produces carbon dioxide and sulfur dioxide, and automobiles are also a key source of harmful carbon. Each industrial activity generates emissions that directly pollute the air, soil, or water.

Decrease the release of harmful gases and control the spread of air pollution.

Conserve whatsoever natural resources are available for our future generations.

Decrease health threats posed by breathed in and otherwise consumed pollution.