What Are the Key Dynamics to Consider in Silo Design?

What Are the Key Dynamics to Consider in Silo Design?

Designing for flow, safety, and long-term performance

When most people picture silos, they often see them as static, unchanging structures—simply large containers for storing powders or bulk materials. But in reality, silos are anything but passive. They breathe, vibrate, flex, and actively respond to the materials inside and the processes around them.

Every time a silo is filled or emptied, internal forces shift, pressure zones form, and material behaviors change—sometimes drastically. If these dynamic actions aren’t properly accounted for, the consequences can be serious: structural damage, inconsistent flow, unexpected blockages, or even safety hazards.

In the world of bulk solids handling, overlooking silo dynamics isn’t just a design flaw—it’s a risk to your entire operation. Because when silo design fails, it doesn’t just slow down your process—it can break your plant.

In this blog, let’s explore how a better understanding of silo dynamics can lead to safer, more efficient, and more reliable material handling systems.

What Do We Mean by “Silo Dynamics”?

Silo dynamics refers to the changing forces and behavior inside and outside a silo during three key phases: filling, storage, and discharge. Bulk materials behave unpredictably, often applying uneven, shifting loads to silo walls.

Even though silos look simple from the outside, they deal with complex internal pressures. These pressures change constantly depending on:

The type of material inside

- How it flows

- How it’s filled or emptied

- External conditions such as vibration, temperature, and moisture

Ignoring these dynamic forces can lead to:

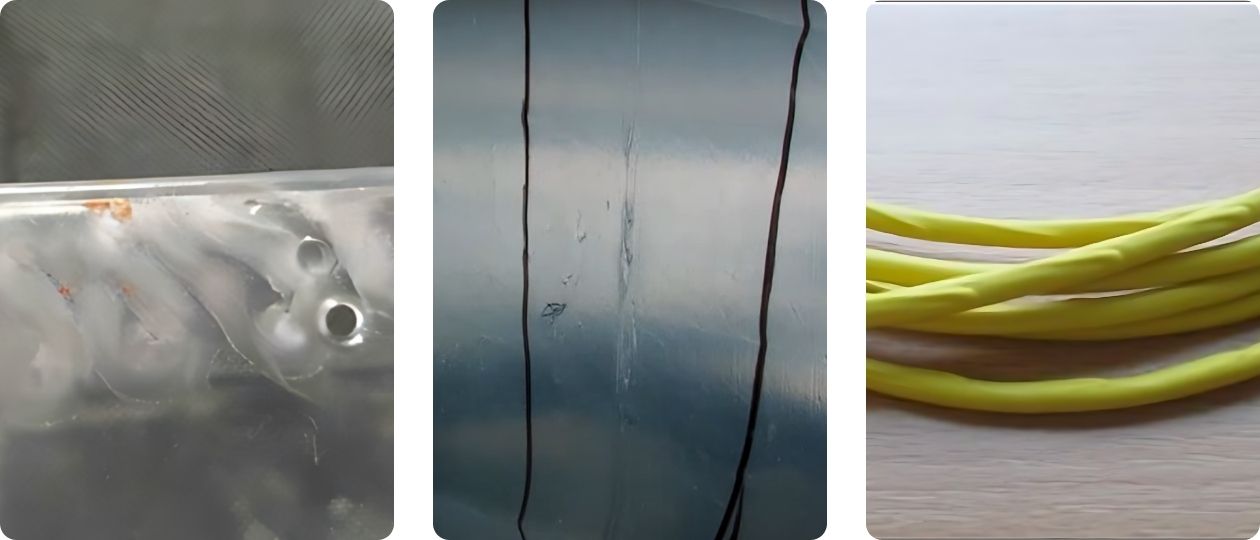

- Deformed silo walls

- Cracks in silo walls

- Uneven pressure distribution

- Material bridging and rat-holing

- Unexpected vibrations

- Frequent maintenance or safety hazards

- Dangerous collapses or uncontrolled discharge

Yes, silos can fail—and the reason is often poor understanding of flow behavior and pressure dynamics.

1. Flow Patterns Matter More Than You Think

Dynamic pressure in silos is largely impacted by the flow pattern of the material.

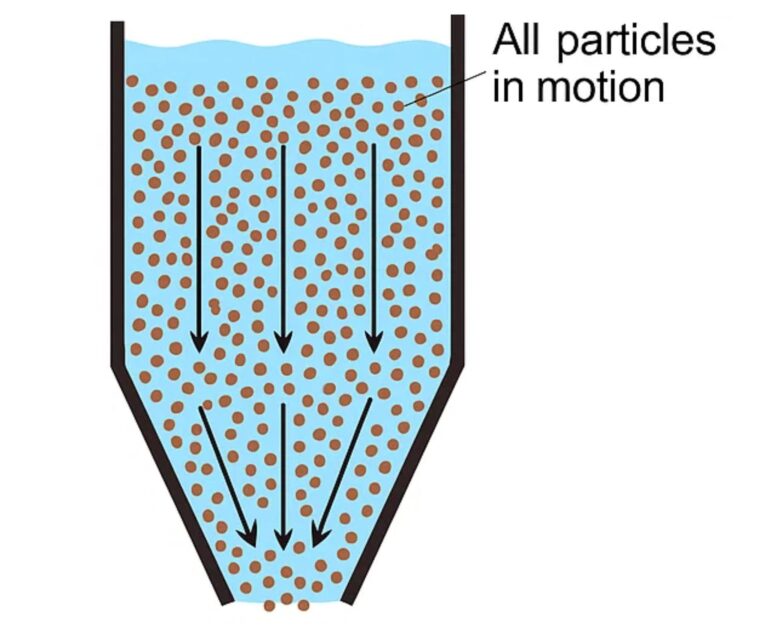

1. Mass Flow:

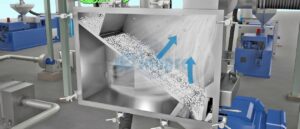

In Mass Flow, material discharges uniformly from all areas, avoiding stagnant zones. The oldest material exists first, following the principle of FIFO.

Good for: Predictable discharge, minimized segregation, and uniform pressure.

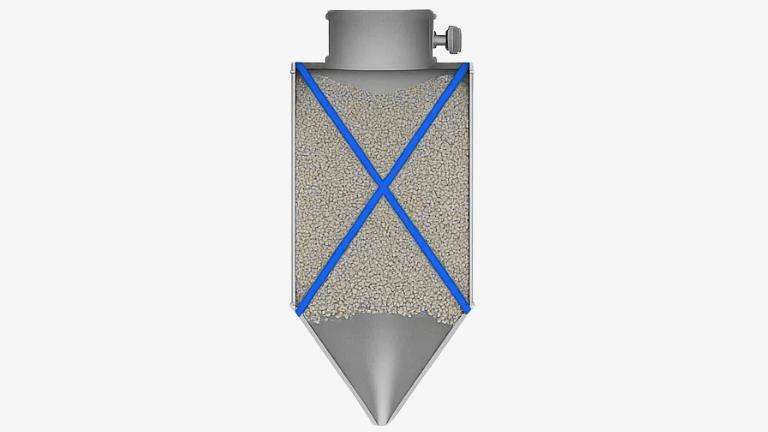

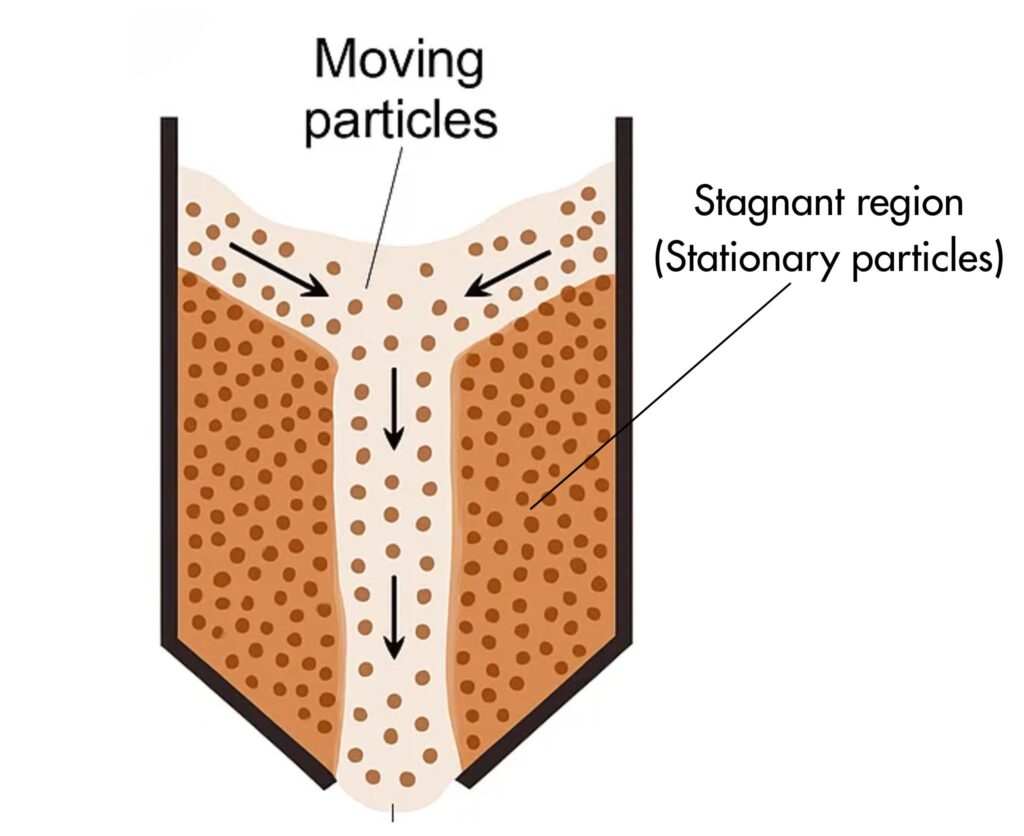

2. Funnel Flow:

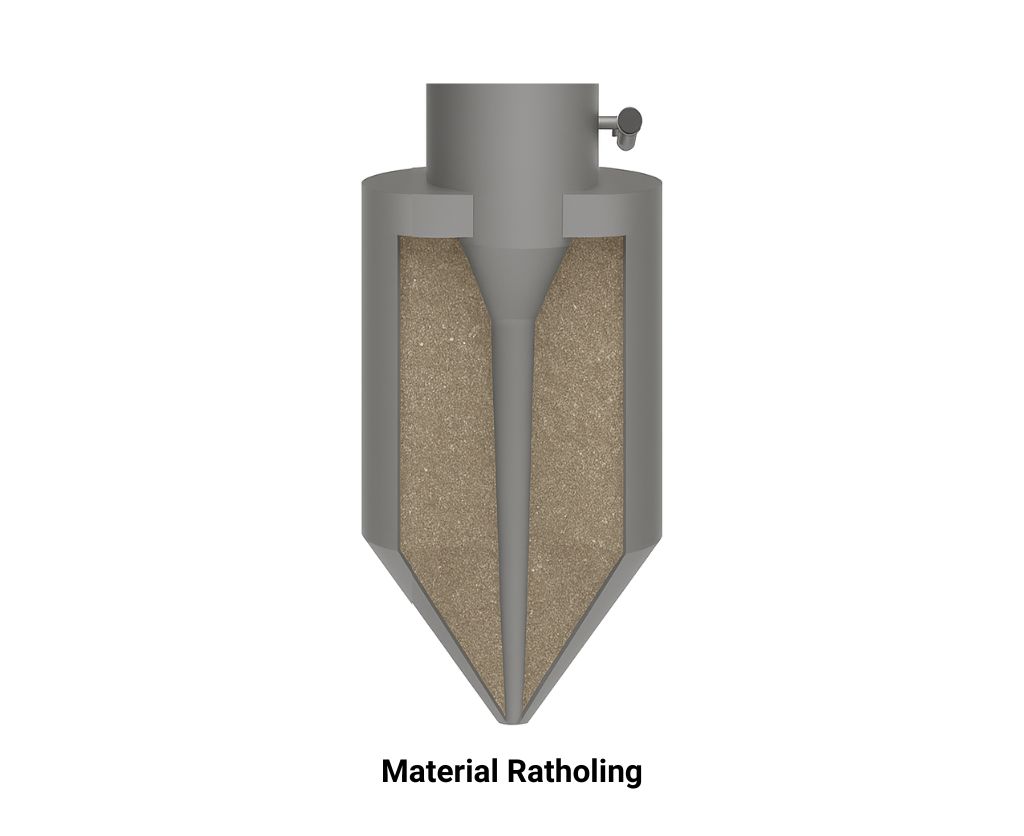

While material flows in a narrow path, the material along the walls remains static.

Bad for: Flow inconsistency, material segregation, material degradation, and uneven stress on silo walls.

Why does this matter?

Because different flow patterns exert different loads on your silo structure. Due to funnel flow, pressure imbalances can form, increasing the risk of structural damage and material degradation in dead zones.

Material Behavior Drives Silo Performance

Because different flow patterns exert different loads on your silo structure. Due to funnel flow, pressure imbalances can form, increasing the risk of structural damage and material degradation in dead zones.

Material Behavior Drives Silo Performance

Things get really interesting here: not all powders, grains, or pellets behave the same. Some powders like to cling to the walls. Others compact significantly under pressure. Some become sticky with humidity. And a few—like flour —may even act explosive under the wrong conditions.

That’s why material characterization is a core step in silo design.

What you must know about your material:

- Bulk density

- Flowability

- Angle of repose

- Wall friction

- Particle size & moisture sensitivity

This data helps engineers simulate how your material behaves in real conditions and design a silo that matches those behaviors—not just one that looks good on paper.

The Real Challenges in Silo Dynamics

Let’s break down some of the most common problems caused by poor dynamic design:

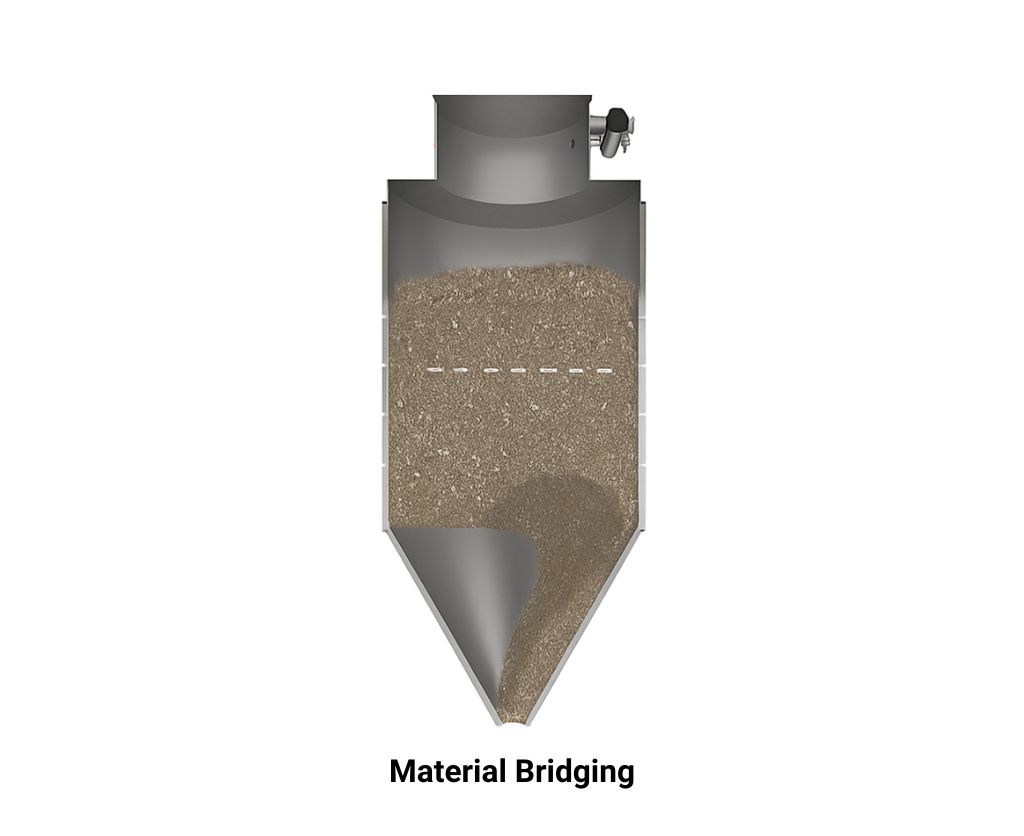

Bridging – Bridging occurs when flow is halted by a dome-like formation of material over the outlet.

Ratholing – Ratholing creates a central flow tunnel, while material near the walls remains stuck.

Segregation – Fines and coarse particles separate

Vibrations – Mechanical vibrations from loading or unloading processes contribute to stress and fatigue in silo walls.

Pressure peaks – Especially during sudden discharge or aeration

Wall collapse – Structural failure of silo walls may happen when funnel flow produces non-uniform loads.

These aren’t rare issues—they’re extremely common across industries like cement, food, plastics, and chemicals.

Tools & Techniques to Analyze Dynamics & Engineer for Performance

Modern engineers have powerful tools to predict how materials will behave in a silo:

Using these tools allows for customized, data-driven silo designs that anticipate and manage real-world challenges.

But analysis is only half the story. Engineering a dynamic-friendly silo is both an art and a science. Here are some best practices to ensure your design stands up to real-world demands:

- Choose the right flow pattern— mass flow ensures a safer and more consistent discharge of material.

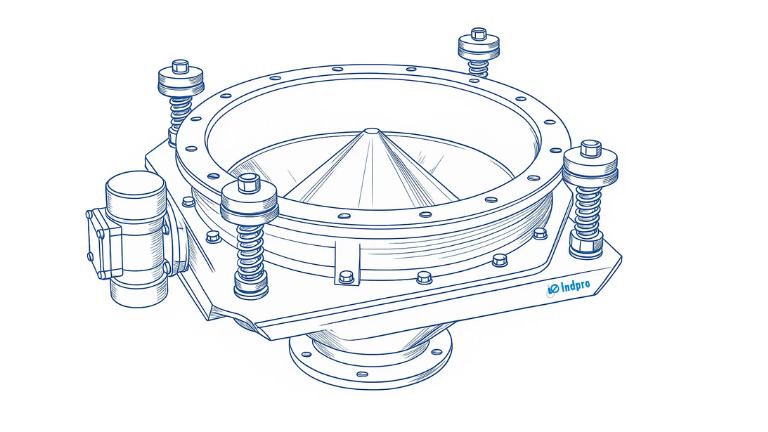

- Ensure reliable discharge and eliminate flow blockages with tools like bin activators and vibrators.

- Select the proper cone angle and maintain smooth internal finishes for better flow behavior.

- Install level sensors, load cells, pressure relief systems, and enable real-time monitoring.

- Use flexible seals and suspension systems to absorb and manage vibrational loads.

Integrated Engineering: More Than Just the Silo

One of the most common mistakes is isolating silo design from the rest of the system.

But your silo must work with:

A well-designed silo system integrates mechanical, structural, and process engineering into one complete solution.

Real-World Example: Dynamics Done Right

A major food processing company once faced chronic bridging issues and silo wall damage. The culprit? An unaccounted-for funnel flow pattern.

We designed and helped them by switching to a mass flow pattern, installing a bin activator and making other design changes. How did we do so? Using DEM simulations for redesign, we not only proved the solution on paper, but also practically. They achieved:

- 100% flow consistency

- Reduced maintenance costs

- Improved structural safety

- No loss of production

Silo failures don’t just happen. They build up over time through misunderstood flow behavior, poor material matching, and ignoring dynamic forces.

Silo dynamics aren’t just academic theory—they’re the silent forces that can make or break your bulk handling system. By understanding flow patterns, material behavior, and structural stress points, you can design silos that are not just strong, but smart.

Ready for an optimized silo system? Let the experts at Indpro help you bring safety, efficiency, and reliability into every aspect of your material handling design