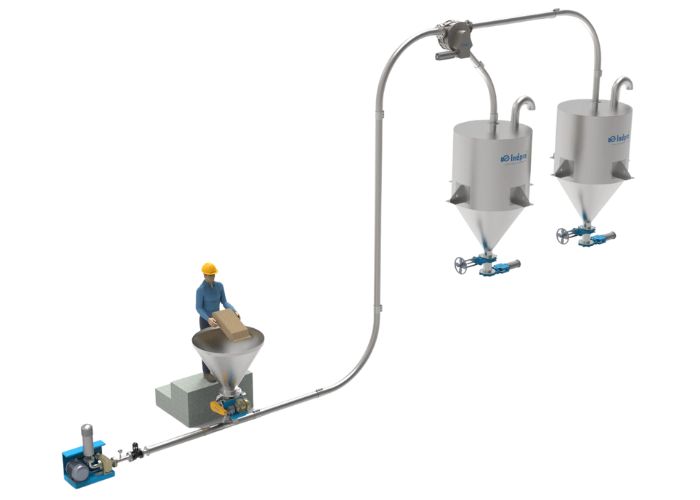

Dense Phase Pneumatic Conveying System (Vacuum)

Dense phase vacuum conveying systems are specially designed pneumatic conveying system for pneumatic conveying of powder, bulk solids through pipes or ducts which are referred to as transportation lines. Usually, dense phase pneumatic conveying systems are used for short-distance conveying. Our dense phase pneumatic conveying prevents any product leakage and contamination on the conveying process.

These pneumatic conveying systems have transport gas velocities in the range of 1 - 10 m/s depending on the product. It pushes material through an enclosed pipe using low velocity, high pressure, and high product to air ratios. The conveyed product either moves in fluidized packets or in slugs or dunes. This system is ideal for fragile materials which degrade when conveyed in dilute phase.

We at Indpro offering customized solutions for dense phase pneumatic conveying systems.

Products Features

Specification

-

Conveying Rate

Low to Medium, typically from 1 - 10 tons/hr

-

Conveying Velocity

1 m/s - 12 m/s

-

Conveying Distance

Upto 15 - 25 mtrs

-

Air Mover

Vane / Water Ring / Pneumatic / Tri-lobe vacuum pump

-

Operating Pressure

Upto -970 mbar(g)

-

Solids Loading Ratio

5 to 100/p>

20+years of

Automating your bulk material transfer

Looking for something more?

Our Dense Phase Pneumatic Conveying System can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USRelated Products

There are many more products and systems which you can explore

Pneumatic Conveying System FAQ's

A vacuum conveying system is a method of transporting materials, such as powders, granules, and small pellets, through a pipeline using a vacuum as the conveying force. The material is sucked through the pipeline by a vacuum prime mover, which creates a negative pressure inside the pipeline. This negative pressure causes the material to be pulled through the pipeline and can be used to transport materials over short and long distances.

Vacuum conveying systems are typically used in industries such as food processing, pharmaceuticals, and chemical manufacturing. It can be used to convey materials that are not free flowing, materials that are hygroscopic, or materials that are sensitive to air flow. Vacuum conveying systems are typically easier to maintain and ensure dust free operation.

Dense phase conveying, also known as low velocity conveying, is a method of transporting materials, such as powders, granules, and small pellets, through a pipeline using a gas, such as air, as the conveying medium. In dense phase conveying, the material is moved through the pipeline in a slow, controlled manner.

The gas velocity is low, typically less than 12 m/s, and the material is transported in a compact, dense phase or plug. This method of conveying is characterized by low gas to material ratios, low material velocities, and low pipeline pressures. It is typically used for materials that are abrasive, fragile, or tend to fluidize.

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry