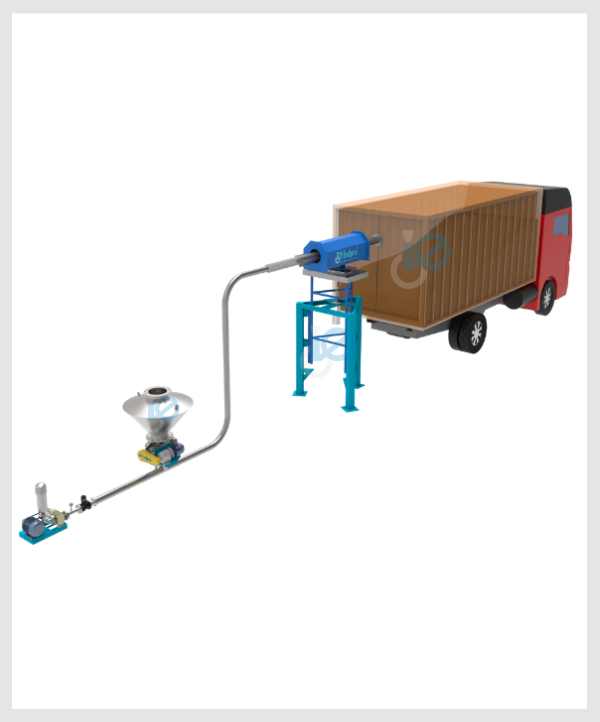

Pneumatic Container Loading System

Pneumatic bulk container loading system provides the ability to make a 90 degree transfer of the product from a low clearance silo into the back of a marine shipping container. Indpro's container loading system is widely used for hassle free pneumatic container loading.

The complete system consists of starting from the upstream end, a rotary valve feeder attached to the discharge spout of a silo that doses the product into a conveying line under positive pressure created by a blower package upstream. This system best fits for pellets, granules, and powders that require maximum cleanliness. As the bulk solids material is stacked into the holder, the passing on-air and residue particles are brought into an incorporated channel beneficiary through the hole between the external extending pipe and the internal passing on the pipe.

This entire pneumatic transport of solids takes place in an enclosed conveying system to prevent the release of residue into the environment. We offer customized pneumatic container loading system according to the requirement of the customer.

For

dilute phase pneumatic conveying system, air is conveyed at high velocity and low pressure, therefore the

pellets, granules or powders enter the bulk container liner at high velocity but in small amounts.

For

dilute phase pneumatic conveying system, air is conveyed at high pressure but low speed, therefore the

pellets, granules or powders enter the bulk container liner at low speed but in big quantity batches. This

method consumes the same time as dilute phase system but requires high pneumatic pressure and thus consumes

more power. It is preferred though where product quality must be maintained. For powder type products, the

bulk container liner is equipped with a ventilation port that returns the dust to a bag/filter house and

thus the environment is kept clean.

Product Features

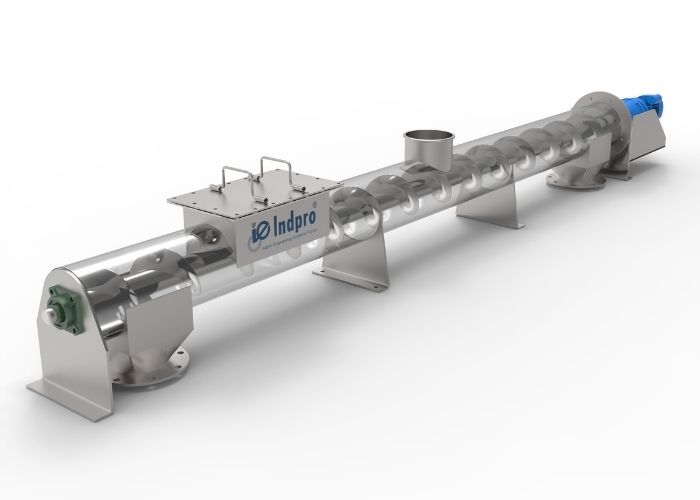

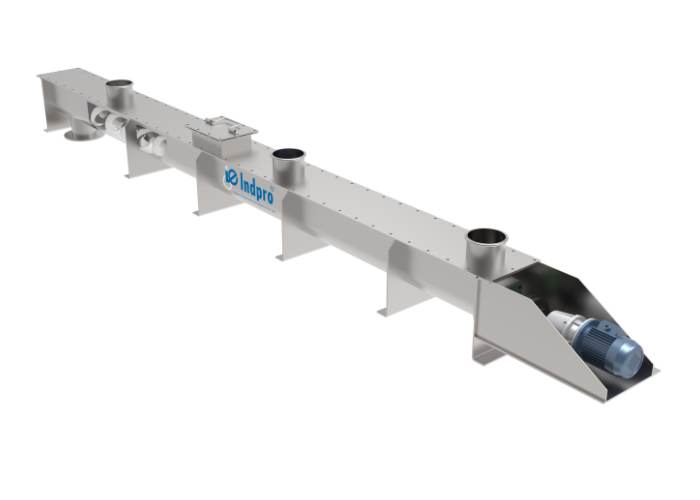

Related Products

There are many more products and systems which you can explore

Indpro

Typically replies within an hour

Send Enquiry