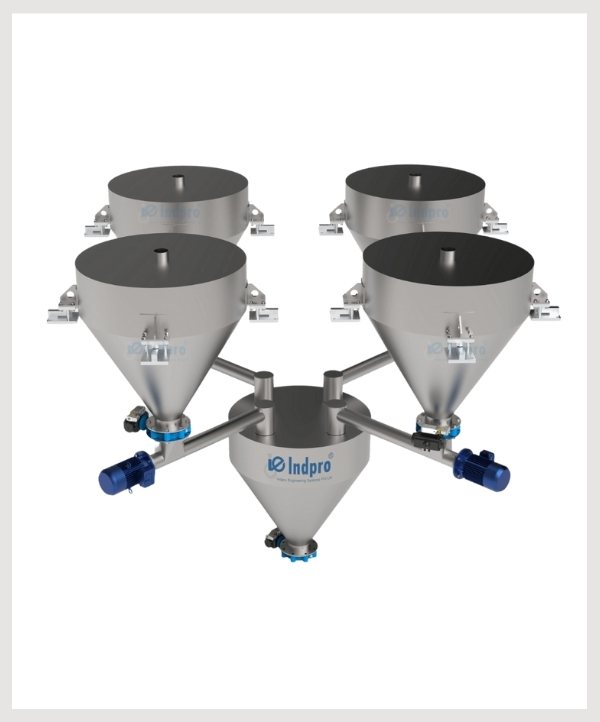

Automated Weighing And Batching System

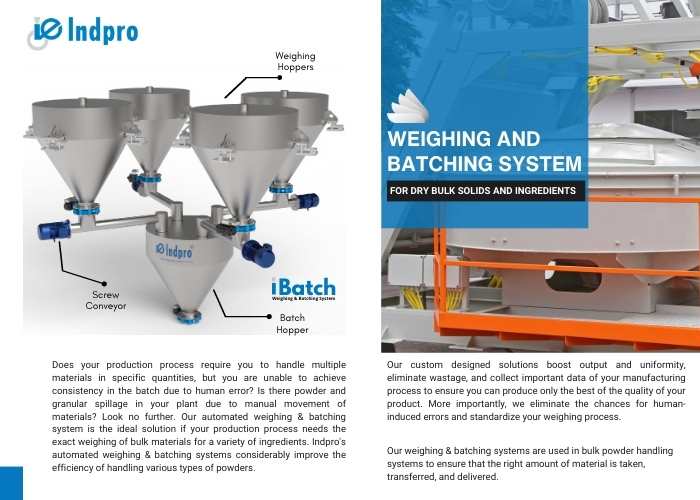

Handling multiple materials and wondering how to weigh every single material precisely and charge into your process equipment? Look no further. Our automated weighing batching system is the ideal solution if your production process needs the exact weighing of bulk materials for diverse ingredients. Automated weighing and batching systems considerably improve the efficiency of handling powder materials. Custom-designed solutions boost output and uniformity, eliminate waste, and collect important data on your manufacturing process. More importantly, we eliminate the chances for human induced errors and standardize your weighing process.

Indpro offers a variety of weigh batching system solutions to suit your specific needs. Our weigh batching plants are custom-built for each application, with complete flexibility in tuning your batch settings.

Weighing and batching systems are used in bulk powder handling systems to ensure that the right

amount of material is taken, transferred, and delivered.

Automated weighing and batching systems can be used to fill containers, such as process vessels, hoppers,

mixers, blenders,

reactors, etc. with the exact amount of powder needed. They can also be used to ensure that the appropriate

quantity of materials is added to a batch of items being mixed. The essence of this

technique is bulk material handling precision and reproducibility. Our solution for your plant begins from how you source your material, either from jumbo bags, small

bags, bulkers, containers, or all of the above, weighing & batching each ingredient to blending your

recipe, filling containers, and/or delivering it to process vessels, packaging lines, or any other

destination, Indpro has the comprehensive selection of equipment you need for any weighing &

batching solution.

Product Features

Benefits

- Ensures that the recipe is followed to the letter

- Scrap, rejections, and wastages are reduced in your final product

- Eliminates dependency on accuracy of manual weighing

- Operator safety features are built-in

- Mixtures that are precise and consistent

- Designed to meet batch time and productivity requirements while remaining within capacity

- Selection and deployment of appropriate mechanised systems ensures easy flowability for any type of material

- Improves the quality of the product

20+years of

Automating your weigh batching

Looking for something more?

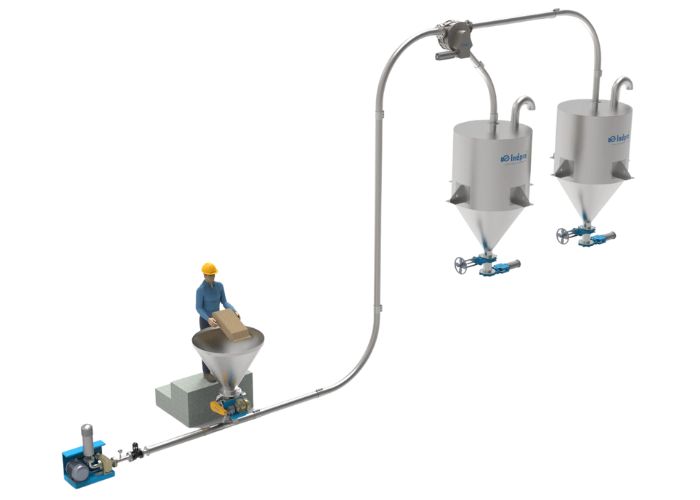

Our Automated Weighing and Batching System can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USThere are several types of weighing and batching systems used in bulk material handling

Related Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry