Pneumatic Conveying Systems

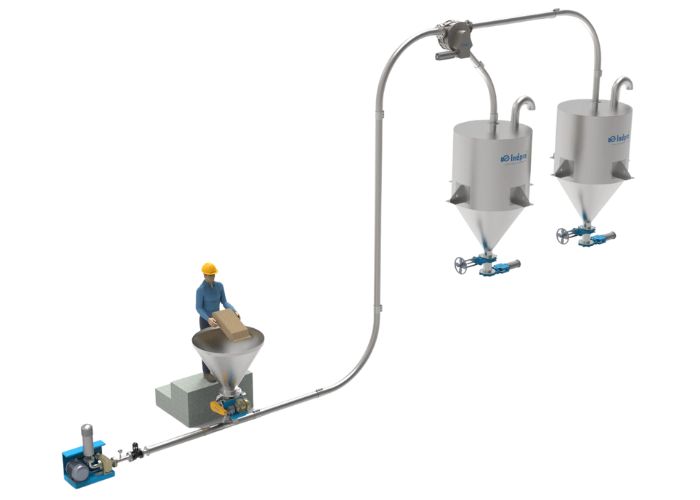

Industries know the importance of pneumatic conveyors in transferring bulk quantities of materials from one place to another. Pneumatic conveying systems are specially designed to hold stream of air and mixture of bulk solid material. A pneumatic conveyor can be classified into two major types according to the mode of transport: dense phase systems (Pressure and Vacuum) or dilute phase systems (Pressure and Vacuum).

Pneumatic conveyor is a necessarily custom-made conveying system & based on product characteristics, particle size, throughput capacity, number of sources, and number of destinations.

Indpro's powder conveying system is assured to be the best pneumatic conveying system solution for any given application. Being application experts and pneumatic conveying system manufacturers, we consistently deliver the best of both the worlds in terms of CAPEX and OPEX.

Indpro’s pneumatic conveying systems come under the brand ‘VAAYU’. The name is derived from the Sanskrit word ‘VAAYU’ which stands for air. The most important aspect of pneumatic conveying is what quantity of air we choose to transfer the material with.

It is our mission to continue developing enhancements in pneumatic conveying technology and components to cater to a broad selection and range of applications.

Indpro Engineering Systems Pvt. Ltd.

We offer turnkey solutions right from raw material handling through small bags, big bags, containers and bulkers including inter process and intra plant material transfer using pneumatic conveying systems.

Types of Pneumatic Conveying Systems

Why choose us?

How we deliver guaranteed performance

-

Expert engineering staff

Highly qualified engineering staff and aftersales support

-

Wide industry experience

19+ years of experience in bulk material handling with over 600+ installations

-

Long performing product life

Use of quality materials and reliable automation systems

-

Easily serviceable equipment

Essential to reaching its full lifetime potential

19+

YEARS OF LONG LASTING AND MUTUALLY REWARDING RELATIONSHIPS

We put our people first

Together, we are a team of engineering experts, working for common purpose to help the industry automate their bulk material handling.

ABOUT USOur Pneumatic Conveying Solutions

Pneumatic Conveying System FAQ's

Pneumatic conveying system is a simple technology by which bulk material in the form of granules or powders is transported through a pipe by using the flow of air or other gas.There can be a variety of different bulk materials from various industries that can be conveyed using this technology. Different materials require different expertise of application engineering to solve the conveying need.

Pneumatic conveying system is designed in two main ways one is pressure or vacuum based conveying.

The bulk materials in the form of granules or powders are transferred through an enclosed conveying pipeline by the force generated by the flow of air or other gas. The pressure or vacuum force and air flow used to convey the materials is generated by air movers such as positive displacement blowers or vacuums.

In a pressure type conveying system, the air flow and pressure is generated at the start of the system. In a vacuum type conveying system, the air flow and vacuum is generated at the end of the system. Therefore, by tweaking the pressure differential and air flow, the system can effectively convey materials from one point to another.

Pneumatic conveyors are used in different types of process plants where material must be conveyed from point A to point B, either within each process or between different sections of the plant.There is an increasing use of pneumatic conveying systems in the Chemical & Petrochemical, Plastics & Polymers, Pharmaceuticals, Beverage & Brewery & Distilleries, and Food industries. read more

The biggest advantage of a pneumatic conveying system over a mechanical conveying system is the flexibility it offers in routing the system in the plant and the distance that a single conveyor can achieve without any intermitted dusting. This makes pneumatic transfer systems a preferred technology in various industrial sectors.

Some of the other advantages are as follows:

- Compact design: The transport of material takes place through pipelines which are easily routed and require minimal space as compared to bulky mechanical systems.

- Low on maintenance: Simplicity of equipment and fewer moving parts directly contribute to reduced maintenance.

- Safe: Since there are fewer moving parts and the systems is low on maintenance, pneumatic conveying systems present less danger to operators and maintenance workers.

- Risk free: More uptime for your processes since there are minimal chances of any breakdown of our pneumatic conveying systems.

- Flexibility: Pneumatic conveying systems can be designed to be routed with flexibility in the plant through every bend and corner.

- Upgradability: Owing to the flexibility, pneumatic conveying systems can be easily modified with design changes and upgrades that can be quickly implemented. Additional feeding and discharge points can be integrated into the system in the future.

- Dust free material transfer: Powder and granules are transported through an enclosed pipeline, the result of which is that all bulk material stays inside as compared to mechanical conveying systems. Air and product separation devices are a part of the system.

- No product loss from system: Being completely enclosed, there is no spillage and leakage, hence loss of material through conveying pipe is zero.

- Hygiene levels are high: Mechanical conveyors are known to create spillages at various junctions, whereas pneumatic conveyors eliminate all such possibilities. This results in minimal product loss, safer working conditions and hygienic transfer of material.

- Material sanitation is ensured: There is no risk of product contamination since the entire system is flushed every operation, and the plant remains cleaner as well.

The basic difference in the two types of system is that pressure conveying systems introduce compressed air at the system inlet which in turn pushes the material through the enclosed piping, whereas in vacuum conveying systems, vacuum is generated at the delivery end in order to pull the material through the enclosed piping.

Both pressure and vacuum conveyors can be used with either of the conveying modes, dense phase (low velocity/high pressure) or dilute phase (high velocity/low pressure). To know which type of system is best suited for your application, you must consult our pneumatic conveying specialists before making a decision. To evaluate your requirement correctly, you should be prepared for the discussion by having answers to the following questions:

- What are the properties of the material being transported?

- Is material or piping degradation a concern?

- At what rate do you want to transfer the material?

- What is the application for the material transfer system?

- What equipment is present before and after the conveying system?

You will have to evaluate a number of material handling characteristics which include conveyability, optimum solid loading ratios, flowability, and degradation.

Pneumatic conveying of various materials requires different approaches. Every material is special in its own right and behaves differently in a pipeline. The only way to find out how a material behaves in a pipeline is to put it in one and convey it! For this purpose we have our own dedicated factory equipped with multiple piped conveying rigs encircling our manufacturing facility. We can adapt our tests to closely match the expected conditions on your site. Having a clear understanding of your material’s behavior in our equipment ensures that your system works right the first time, every time. We have already successfully conducted test trials on 250 plus materials at our Indpro Technical Centre.

Want to know more about pneumatic conveying systems?

Tell us more about your application needs.

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Global Business Associates