Tube Chain Conveyor - DisKCon

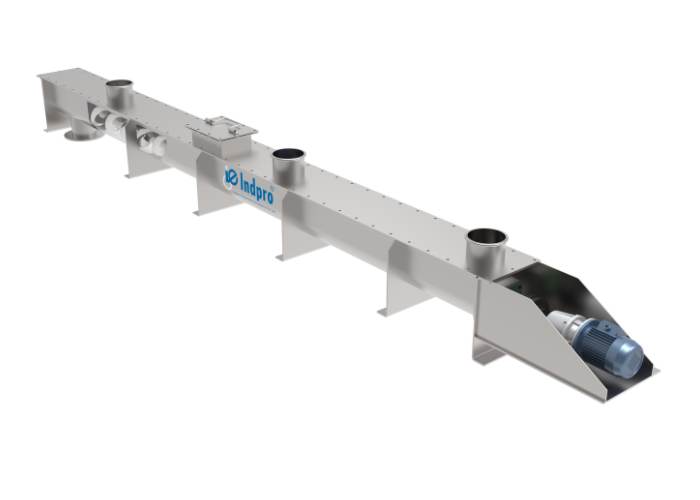

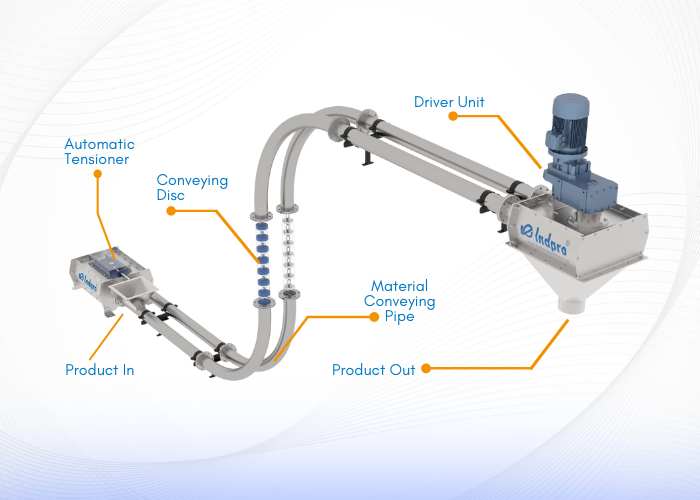

Indpro’s tubular chain conveyor - DisKon is a fully enclosed conveying system, consisting of a tubular casing through which the product is conveyed. Material is dragged along the tubing, pushed by specially made polymer discs which have incredible compressive strength. This tubular drag conveyor systems operation is totally dust free, which eliminates the need to have a dust collection system. It can be used for handling a variety of bulk solids, no matter how abrasive, toxic, explosive or adhesive they are. Bulk material, right from micron sized fine particles to granules up to 50 mm can easily be conveyed in Indpro’s tube chain conveyor.

The low chain speed ensures gentle handling of the products. This preserves particle integrity with no further size reduction. It is, in fact, so gentle that we have been able to achieve no breakage on nearly all types of products. Another advantage is that the product is conveyed with no particle declassification – particle distribution consistency is maintained as it was before conveying.

Product Features

Applications:

-

Pharmaceuticals

Use it to convey powders that go in their manufacturing process.

-

Plastic and Polymer

Use it to convey fragile polymer pellets, granules and explosive powders.

-

Chemical

Use it to convey fragile, explosive, photosensitive, hygroscopic powders, either raw ingredients or finished products.

-

Food

Use it to gently convey cereals, grains, coffee, peanuts, almonds as well as small sized solids such as sugar, pepper, etc.

19+years of

Automating your bulk material transfer

Looking for something more?

Our Tube Chain Conveyor can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USAny Industry

Just about any industry that needs to convey material gently and quickly can speed up their process by integrating DisKCon into their setup. Material handling automation has become of paramount importance to the industry.

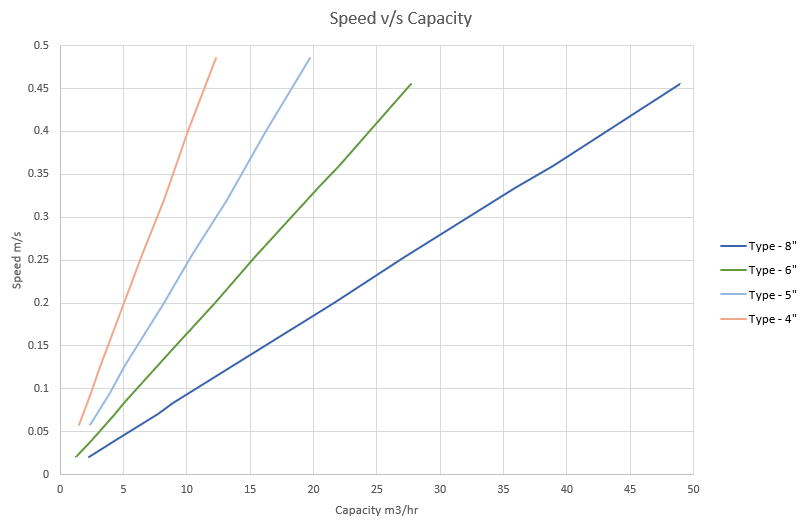

| Type - 4" | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity (m3/h) | 1.5 | 2.5 | 3.2 | 5.1 | 6.5 | 8.2 | 10.1 | 12.3 | |

| Velocity (m/s) | 0.06 | 0.1 | 0.125 | 0.2 | 0.26 | 0.32 | 0.4 | 0.49 | |

| RPM | 3.3 | 5.6 | 7.2 | 12 | 14.6 | 18.6 | 22.8 | 27.8 | |

| Type - 5" | |||||||||

| Capacity (m3/h) | 2.4 | 4 | 5.1 | 8.2 | 10.4 | 13.2 | 16.2 | 19.7 | |

| Velocity (m/s) | 0.06 | 0.1 | 0.125 | 0.2 | 0.26 | 0.32 | 0.4 | 0.49 | |

| RPM | 3.3 | 5.6 | 7.2 | 12 | 14.6 | 18.6 | 22.8 | 27.8 | |

| Type - 6" | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity (m3/h) | 1.3 | 2.5 | 4.4 | 5.1 | 8.7 | 12.2 | 15.3 | 20.3 | 22 | 27.7 | |

| Velocity (m/s) | 0.02 | 0.04 | 0.07 | 0.085 | 0.14 | 0.2 | 0.25 | 0.33 | 0.36 | 0.46 | |

| RPM | 1 | 1.9 | 3.3 | 3.9 | 6.7 | 9.4 | 11.8 | 15.6 | 16.7 | 21.2 | |

| Type - 8" | |||||||||||

| Capacity (m3/h) | 2.2 | 4.4 | 7.7 | 8.9 | 15.4 | 21.6 | 27.1 | 35.9 | 38.9 | 49 | |

| Velocity (m/s) | 0.02 | 0.04 | 0.07 | 0.085 | 0.14 | 0.2 | 0.25 | 0.33 | 0.36 | 0.46 | |

| RPM | 1 | 1.9 | 3.3 | 3.9 | 6.7 | 9.4 | 11.8 | 15.6 | 16.7 | 21.2 | |

Related Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.