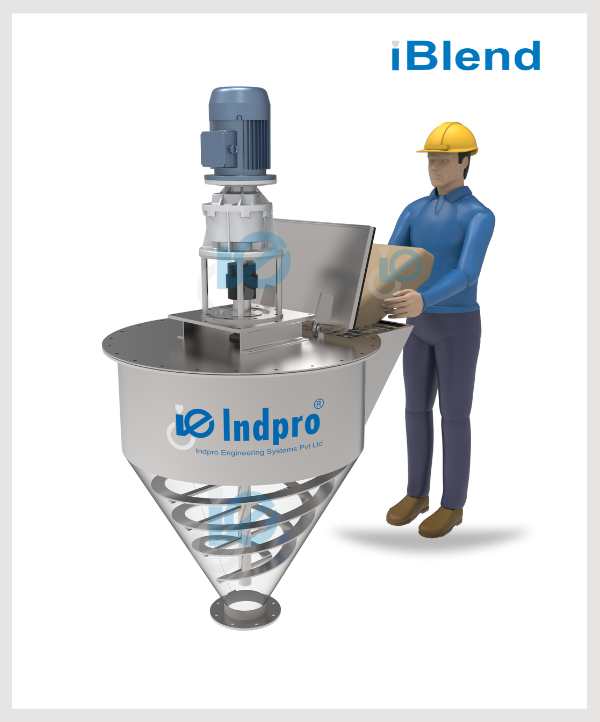

Vertical Ribbon Blender

Indpro's vertical ribbon blender is purpose-built for the gentle blending of solids. The ribbon blender is installed at the center of the conical vessel and powered with an electric drive. The blending ribbons' profile gently mobilizes the material and generates turbulence in all directions ensuring a uniform mix. Backed with decades of experience in this domain Indpro offers a wide range of vertical ribbon mixer. They are used in many industries like paint, ink, chemical, food processing, beverages, pharmaceuticals, cosmetics, plastics etc.

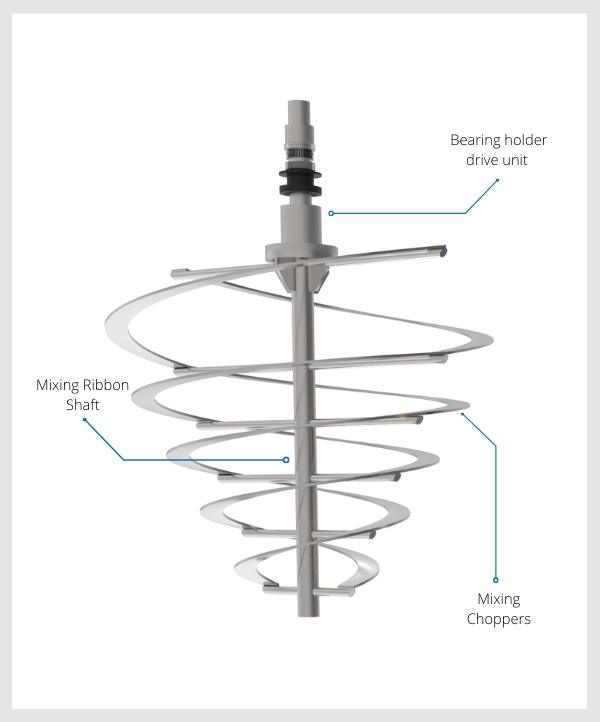

Indpro's vertical ribbon blender is a high speed, high capacity batch mixer for the homogeneous blending of dry, free-flowing solids. It comprises of a conical vessel and a specially designed double helical ribbon agitator rotating within. Ribbon blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast and efficient blending.

The dimensions and configuration of the ribbons are carefully balanced to

provide movement of material within the container that avoids dead spots and gives rapid product discharge. The

mixer is available in machine sizes ranging from 100 to 5000 liters.

We are a leading vertical ribbon blender manufacturer & supplier in India. We manufacture customized ribbon blenders

as per the requirement of the customer or the industry. They are used in many industries like paint, ink, chemical,

food processing, beverages, pharmaceuticals, cosmetics, plastics etc.

Product Features

Customized Features

- Wear resistant liner plates for abrasive products

- Ribbon agitator for multiple discharge positions

- Good Manufacturing Practice (GMP) models

- Spraying system for liquid injection

- Optional jacketing for heating, cooling

- Inspection & cleaning windows can be provided on the body

- Explosion-proof motors, variable speed drives along with electrical control panel

- Manually or pneumatically operated butterfly valve, slide gate valve, diaphragm valve, etc. for discharge

19+years of

Automating your bulk material mixing

Looking for something more?

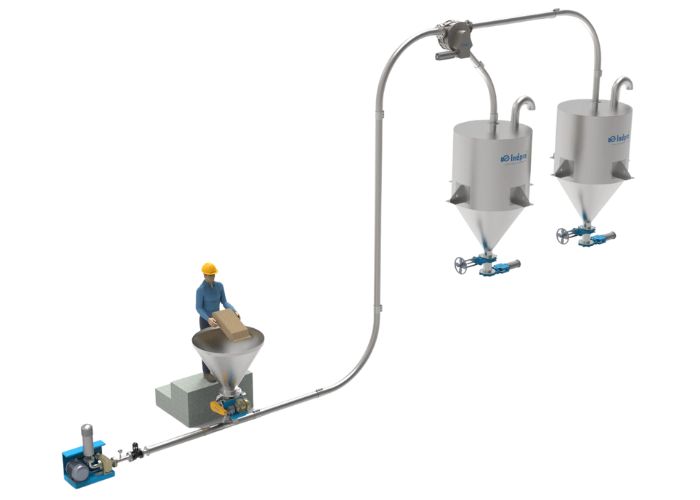

Our Vertical Ribbon Blender can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USRelated Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry