Grain Destoner

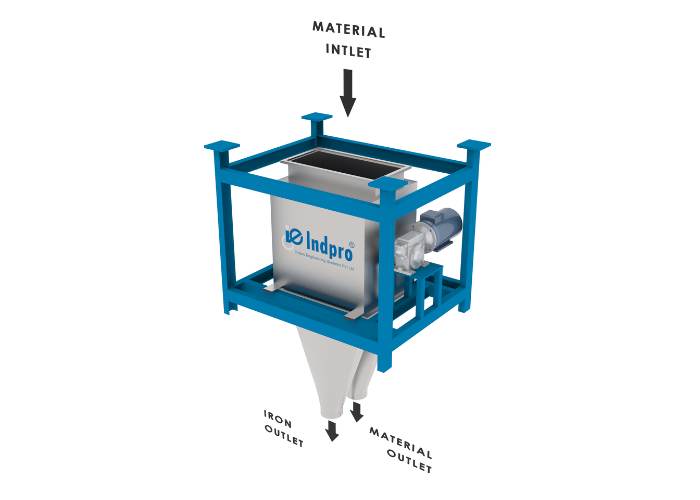

Indpro's Destoner is the ideal solution for removing high density contamination from a continuous flow of grains such as, rice, wheat durum wheat, corn (maize), rye, soybeans, oats, buckwheat, spelt, millet and rice to name a few.

The deck comprises of a perforated screen, through which an upward draft is created by centrifugal fan. Due to difference in density of product and the contaminants, the heavy particles such as stones are retained at the bottom of this fluidized mass and product remains a float. Air velocity can be adjusted to achieve the optimal degree of separation. The oscillating action of the screen causes the heavy particles to work their way to the upper end of the deck from where they are expelled through stone outlet. The stone-free grain floats on cushions of air toward the product outlet located at the lower end of the deck. Discharge occurs at both outlets through a rubber chute, which avoids air ingress.

The Destoner machine is used in various application such as rice mills, grain mills, flour mills etc. In this grain destoner air volume can be adjusted to achieve an optimal degree of separation.

The throughput capacity vary according to the type of product to be handled and contamination in it. Variety of products can be handled – Rice, Wheat, Millets, Sorghum, Barley, Malt etc. Typically, the capacity ranges from 8 TPH to 20 TPH.

Product Features

Technical Specification

-

Throughput capacity

Up to 12 tons per hour

-

Motor

0.75 kW X2

-

Surface finish

Powder-coated

-

MOC

Mild steel (painted or galvanised)

Stainless steel

19+years of

Automating your grain handling

Looking for something more?

Our Grain Destoner can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USRelated Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.