Solutions For Chemicals & Petrochemicals

With an increased use of virgin polymers in various products and an increased use of man-made fibers in textile industry, petrochemical industry is required to produce the building blocks ingredients for the most of the chemicals in abundance. To help address this growth we offer a solution to this sector in the area of bulk solids handling from the receipt of the raw material, various intermediate stages till finished product packaging.

Chemical and agrochemical sector is also growing at a rapid pace. We provide solutions to this sector in the area of pneumatic conveying of dry powders & filtration solutions for handling of various powders having normal, hazardous, explosive and active nature. Closed loop type conveying systems are offered for hazardous, explosive & sterile products using an inert gas as a conveying media. Hygienic, quick clean and no residue design are standard features of our products for such industries. Our systems are rated to be operated in either safe or hazardous areas, with various certifications such as flameproof & ATEX.

Solutions offered to chemical industry

The entire chemical sector in India is rising with increased consumption across the country. Increased requirement of production gives rise to the need for automation in production aspects. Bulk material handling in the Chemical, Agrochemical & Petrochemical industries plays a vital role in nearly all aspects of the process, from raw materials handling, inter-process manufacturing and post process packaging. There are multiple challenges that are faced in production floors, which include productivity and production losses due to spillage and dusting, physical handling of hazardous raw materials, environmental concerns, accidents, and so on. We provide solutions for pneumatically conveying and dust collection of dry powders for handling a wide range of products, including conventional, hazardous, explosive, and active ingredients. Our key responsibility lies in accurately delivering all raw materials required in your production to your process equipment such as mixers, based on their flow qualities and proportion in the formulation.

Indpro Engineering Systems Pvt. Ltd.

Our expertise enables us to solve even the most difficult of challenges for chemical & petrochemical material handling issues.

Materials We Handle

types & grades of chemicals & petrochemicals

Challenges & Solutions

Handling different materials has it challenges, and we have the right solutions to cater to them

Raw Material Unloading

Is done through several equipment such as Bag Dump Station, Big Bag Unloading Station and Automatic Bag Emptying Machine.

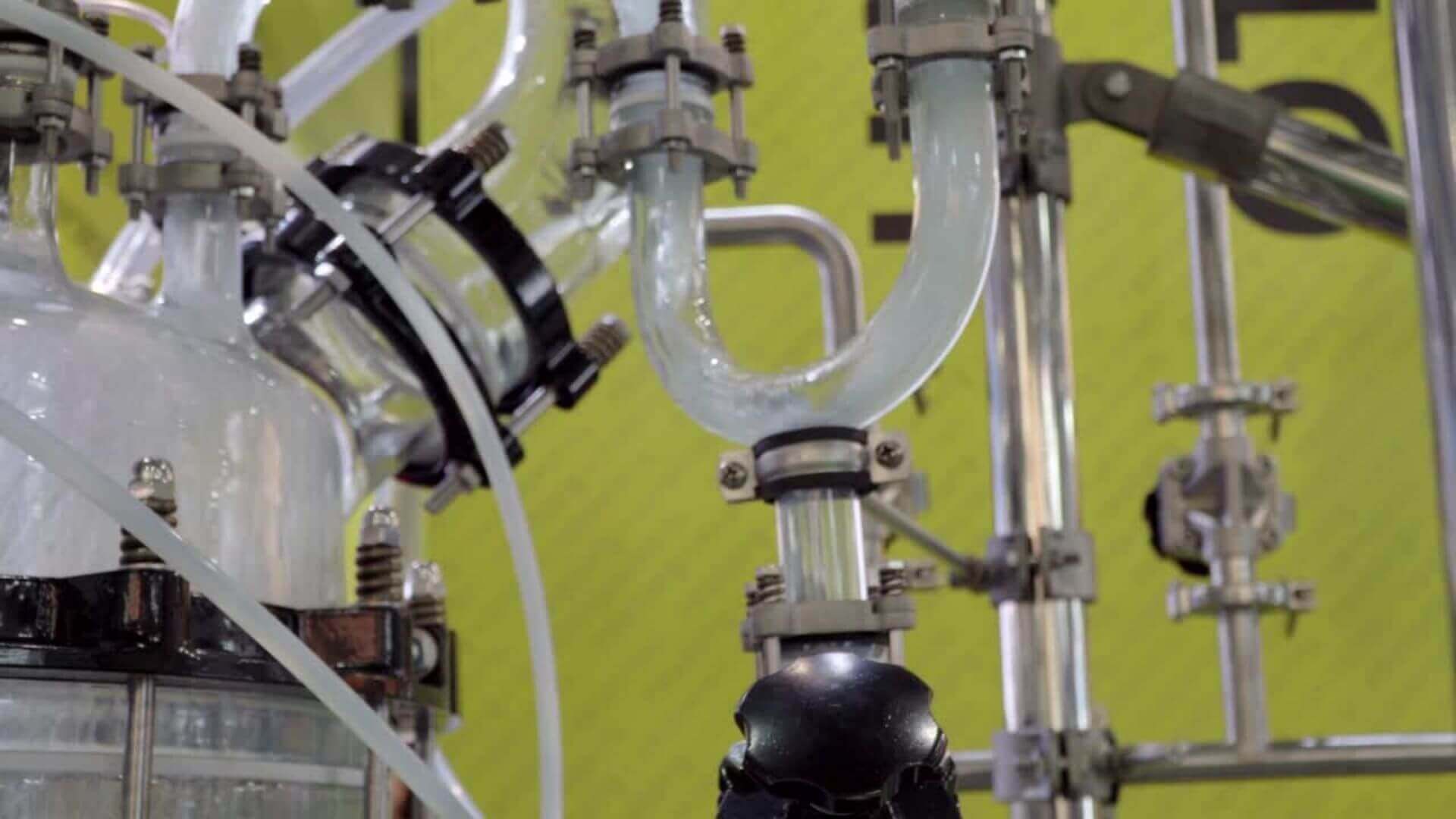

Pneumatic Conveying System

Is used for transferring material from point A to point B for plastic & polymer using high levels of flexibility. These are practically maintenance free devices.

Storage Silos & Hoppers

Are required for storing powders before sending them to the process area. Weighing makes sure right amount of powders are consumed.

Ribbon Blenders & Horizontal Blenders

Are used for the blending of different types of chemical products. Variety of grades of chemicals can be homogenized using our blending solutions.

Bagging Machines

Allows to automatically weigh and fill powders, granules, flakes, fibrous materials and large particles into various sizes of bags, ranging from 25 kg bags to jumbo bags.

Filtration Systems

Are used as dust collectors to separate dust particulates from dusty gases and

keep the process area free of dust.

What people are saying about Indpro

An honest endorsement from our satisfied clients will help you understand how our services have made a difference in their businesses and are ready to make in yours.

In my opinion, any engineering team must understand the requirements, deliver on schedule, and meet those requirements. We have found that the team at Indpro excels in all three areas. Their strong communication skills and the solution they provided for our 50 kg HDPE drum lifter and tilter system made a noticeable difference in our company.

Indpro delivered excellent solutions using cutting-edge techniques. The quality of their work was outstanding and everything was delivered on time. It was truly a pleasure to work with such a dedicated and professional team. I highly recommend Indpro for their exceptional engineering services.

Sunil Rajput

Chembond Material Technologies Pvt Ltd.

We have implemented a closed loop conveying system for our explosive fine powders. The conveying system works very well while using nitrogen as the conveying media. The technicians at Indpro are knowledgeable and provide very capable installation services. Indpro team is a delight to work with and they helped us complete the installation to meet our plant schedule.

Ranjan Sahu

Coromandel International Ltd.

The automation and efficiency offered by Indpro's powder storage, conveying and batching system has helped us significantly reduce manual intervention and issues of dusting. The system's integration with our existing setup was seamless from bag unloading to processing machinery, and the increased throughput speaks volumes about its performance. Their system is a must-have for any bulk material handling operation.

Siddhartha Sahoo

Wacker Metroark Chemicals Pvt. Ltd.

Reliability and precision are paramount in the agrochemical industry. Indpro’s conveying system has exceeded our expectations. The system's ability to unloading fine powders from small & jumbo bags with no dusting aligns perfectly with our stringent quality standards. They have helped us seamlessly connect our mixing and milling equipment.

Saibaba

Vantech Chemicals Ltd.

The selection of technologies, platforms, and system design were handled jointly by the team of Indpro engineers. Project and quality management as well as schedule control were as agreed to and on par with the highest standards. Their professional approach, understanding of our needs, and flexibility in decision-making during execution led to building a system that precisely matched our requirements. Generally, I think the basic engineering and detailed engineering teams deserve the highest marks for their work. We plan to maintain our relationship with Indpro to build more bulk material handling solutions for our upcoming plants in the future.

Neeraj Bhale

Ineos Styrolution India Ltd.

Indpro’s dense phase & dilute pneumatic conveying systems have been a game-changer for us in polyester chips handling. We have been using multiple systems of varied capacities for the last few years. From handling delicate granules, their system handles it all with finesse. The system's reliability is perfect, a fit and forget kind of system. We are satisfied using with their conveying for our transportation processes.

Anil Babu Tiwari

IVL Dhunseri Petrochem Industries Ltd.

Choosing Indpro's pneumatic conveying system was a significant step toward sustainability for us. The system's efficiency in handling quartz powder has allowed us to reduce dusting and contribute to a cleaner environment, while reducing our dependency on labour. Their dedication to environmentally friendly solutions aligns perfectly with our mission.

Y S Rao

Aequitas Estones Pvt. Ltd.

The entire team at Indpro is professional and has helped us immensely from ordering to system handover. The sales and engineering teams answer any questions quickly, and the return on investment is easily justified. Their installation and service team helped us commission the system with online support only, which we found quite unique. Despite sand being an abrasive material, the system is well designed to take care of it without any wear or tear. We have been using the system for over 2 years now.

Quang Thieu Ba Duong

Frit hue joint stock company

Indpro

Typically replies within an hour

Send Enquiry