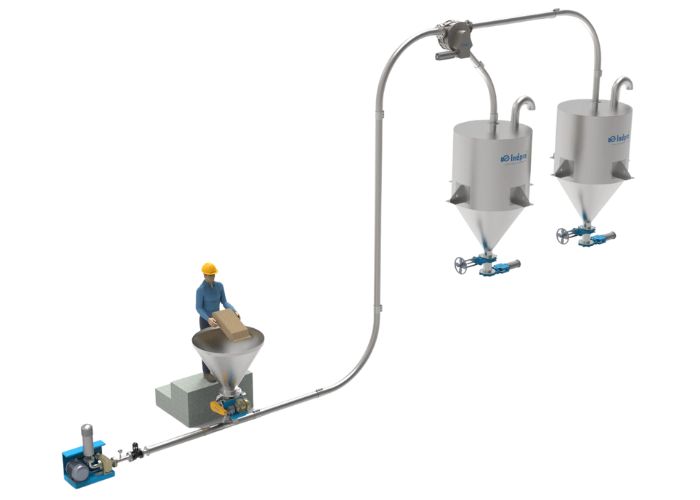

Closed Loop Pneumatic Conveying System

Closed loop pneumatic conveying system is a specially designed system to convey the material to multiple discharge points for the hygroscopic, sterile, perishable hazardous material or for the material there is no contamination is required during the production process.

One of the primary features of closed loop system is that the conveying gas can be recovered and reused for conveying. Nitrogen is the most popular choice for most plants that wish to go with this system. Requirement for expensive explosion prevention devices is eliminated as the inert atmosphere nullifies this hazard.

Do get in touch with us if you would like to know more about pneumatic conveying system.

Product Features

Specification

-

Conveying Rate

Low to High, typically from 1 - 40 tons/hr

-

Conveying Velocity

15 m/s - 25 m/s

-

Conveying Distance

Upto 100 - 200 mtrs

-

Air Mover

Positive displacement tri-lobe blower / FD fan / Ring channel blower

-

Operating Pressure

Upto 1000 mbar(g)

-

Solids Loading Ratio

1 to 10

20+years of

Automating your bulk material transfer

Looking for something more?

Our Close Loop Pneumatic Conveying System can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USSpecial Features

Sealed System:

- No airborne contaminants

- Contained emissions

- Clean enclosed method of conveying

- Re-circulating gas = Economic Dry Air Conveying

- Economic inert Gas Conveying

- Multiple destinations & single common filter

Nitrogen/Inert Gas Conveying:

- Hazardous products transported safely

- Explosion panels and venting eliminated

- Economic conveying by recirculation – minimal gas usage

Dry Air Conveying:

- No caking/agglomerating

- Microbiological growth inhibited – ideal for food products

- Product stays in good condition dry & free flowing

- Reduced maintenance & cleaning

- No condensation or need to lag/insulate pipes

- Improved filter performance

- Sterile Air Conveying

- HEPA filtered air is introduced to the system to ensure biological contamination is eliminated

Related Products

There are many more products and systems which you can explore

Pneumatic Conveying System FAQ's

A closed loop pneumatic conveying system is a type of pneumatic conveying system that uses an inert gas to move materials through a closed pipe or tubing. The system is closed in the sense that the material being conveyed is enclosed within the piping and gas used for conveying is recirculated in the system. This can be beneficial in certain applications, such as when conveying hazardous materials or when the material being conveyed is sensitive to contamination. The most common inert gas used for these systems is nitrogen.

In a closed-loop pneumatic conveying system, the material is continuously fed into the system and is conveyed to the desired location. Any variations in the material flow rate or pressure are continuously monitored and adjusted using sensors and control valves, this ensures a stable and consistent material flow rate.

Closed-loop systems are advantageous because they can reduce human intervention, increase safety and reliability, and lower costs and other hazards involved with handling the products.

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.