Powder Bridge Breaker

The Ultimate Solution for Powder Bridging and Silo Discharge Problems

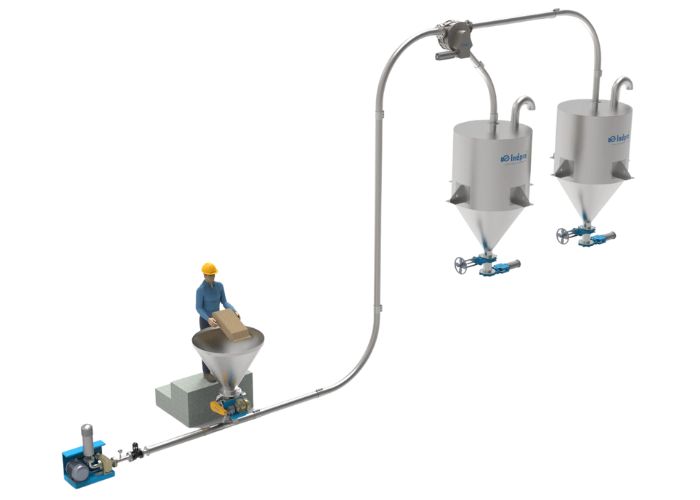

While managing a variety of different poor flowing materials, iRotoCon is intended to assist in discharging materials from storage silos and hoppers in a controlled manner. RotoCon is designed to avoid powder bridging in hoppers and silos due to it’s special rotary blade design. Along with preventing powder bridging, iRotoCon also ensures a dependable, constant, and controlled rate of discharge through one or multiple outlets.

iRotoCon, a very creative and efficient substitute for the traditional sweeping auger, bin activators, and other flow aiding mechanisms. It is a unique piece of equipment that accurately and uniformly feeds mechanical & pneumatic conveying systems, mixing vessels, reactors, dryers and bagging machines. Although the iRotoCon performs a variety of tasks, it is best known for reducing material bridging, segregation, and ratholing in poor flowing materials.

Usually, it is attached to the bottom of the storage silos or hoppers and it has bottom panel with thin, flat central

vanes that revolve inside the hopper. When the central vane slowly rotates, the material is delivered to one or more

discharge ports and is radially pushed outwards. As a result, conditions for mass flow are created and the material

level in the hopper is able to decrease uniformly. iRotoCon’s large intake diameter is greater than the critical

arching diameter of many powders. The feeder rotates slowly and softly due to its robust construction and minimal

maintenance requirements. Its unique design makes it possible to feed consistently and uniformly through all

outlets.

iRotoCon is capable of handling a broad range of products and materials from numerous industries, including food,

chemical and plastic. iRotoCon is available in a range of diameters from 1000 mm to 3000 mm. Usage of iRotoCon has the

potential to raise profitability and prevent operators from hammering hoppers.

Product Features

iRotoCon can be availed with the following options:

Applications

-

From Silo to Bagging Machine.

-

From hopper to batching process.

-

To loss-in-weight feeders.

-

Either under storage silos or inside storage hoppers.

20+years of

Automating your bulk material transfer

Looking for something more?

Our Powder Bridge Breaker can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USAdvantage:

- Uniform feeding to various ports.

- Uncomplicated, rapid assembly and disassembly.

- Powder bridges are prevented.

- The amount of floor space and needed height are both decreased by flow splitting

Benefits:

- Using a speed-adjustable motor, the feeding rate is easily controlled.

- Gentle product discharge.

- Easy maintenance & quiet operation with minimal drive power and noise.

- The gearbox and motor are easily accessible.

- Mass flow that prevents segregation.

Related Products

There are many more products and systems which you can explore

Powder Bridge Breaker FAQ's

Powder bridging occurs when the materials in a silo or hopper interlock and form a strong arch or rat-hole above the intended outflow. Powder bridging causes the materials retained in the silo to become trapped. Silos should be fitted with the appropriate discharge assist to avoid this and ensure proper and efficient discharge.

There are multiple types of silo discharge system is available in the market but RotoCon is a very creative and efficient substitute for the traditional sweeping auger, bin activators, and other flow aiding mechanisms. Because of its circular motion, which assures a consistent draw-down of materials and follows the "first-in, first-out" concept, it completely removes the risk of material bridging and segregation. RotoCon makes it simple and practical to stop powder bridging and discharge problems in silo systems without the use of vibration or aeration. RotoCon provides the following to assist to reduce powder bridging:

- Active silo outlet with a large diameter.

- Removal of empty space where items could gather.

- Low headroom architecture that maximises silo contents.

- Regulating discharge rate.

- Feeding that is constant through a wide range of throughputs.

Because to differences in the physical properties of its components, flow operations can create segregation, which is the uneven distribution of parts in a powdery product. Segregation during powder handling and storage can have a number of detrimental effects, and visual assessment of segregation is difficult. RotoCon is the finest alternative for preventing powder segregation during mass flow discharge.

Although the number of installable discharge ports depends on the size of the feeder, we can install as many as you need. Moreover, to prevent piping from overlapping in applications involving conveying, a maximum of three ports can be placed.

If two discharge ports are installed symmetrically, their capacities are identical. The variation in material throughput through the two outlets will not exceed 1%.

The largest inlet diameter of feeders we have manufactured so far is 120 inches.

There will be some residue on the vanes and bottom plate, although even the situation will vary depending on the material's physical characteristics. There are, however, extra tools that can help decrease residue even further. Call us for further information.

RotoCon can discharge particles up to 50 mm.

No particular limits have been set. If you specify hopper capacity and height, we will propose the optimal inlet diameter and height of the feeder.

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry