Flexible Screw Conveyor

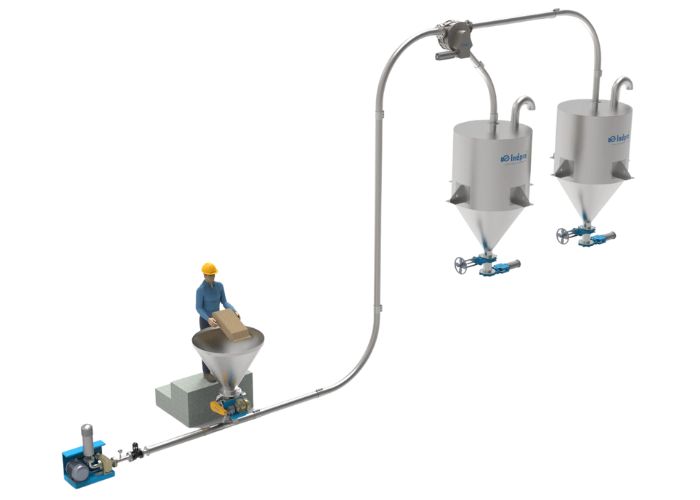

Indpro flexible screw conveyor is a one-moving-part conveyor capable of securely and reliably carrying a wide range of free-flowing powders, granules, or pellets throughout your plant. The flexible screw conveyor can transport materials anywhere, from horizontal to vertical, over obstacles and equipment, and may also be used to carry materials up and down floors.

The flexible conveyors can easily move items from a material unloading station, bag dump stations , storage bins or processing equipment to a line of further processing equipment or packing equipment.

They are popular in the pharmaceutical, chemical, food, and plastics sectors, and they are great for powders and granules. They transport powders and granular materials without product separation. In fact, the force of the rotating spiral helps in remixing the material using an internal helical screw inside the pipe due to the high conveying speed. Our flexible screw conveyor are incredibly easy to operate and clean during batch changeovers due to quick release coupling provided at all junctions. The inner spiral can easily be removed to access and clean the internals.

Basically, several different names of flexible screw conveyors used in industries called auger conveyor, spiral screw conveyor, helix conveyor, helical conveyor, shaftless screw conveyor. In addition to the drive, gearbox, inlet and outlet, the screw conveyor is also composed of a conveying tube and a flexible spiral. In a single unit, conveyors are usually no more than 6 metres long. In case longer conveying distances are required, multiple units can be coupled together to achieve the required length of conveying.

The Indpro flexible screw conveyor is particularly cost-effective, with a minimal initial investment and long-term labour savings. Our versatile screw conveyors may be easily integrated with a wide range of powder handling equipment both upstream and downstream, as well as a portable base frame with wheels.

Product Features

Applications

-

For elevating powders and granular bulk materials into blender, mixers, packaging machines or storage bins.

-

For unloading and transferring material from big bag unloader to storage, mixing or process equipment.

-

FSC has an advantage to couple a multiple number of pipes to one another and easily convey the material without disturbing the other process line on the shop floor.

-

Indpro flexible screw conveyor is used for a continuous or batch mixing process like from a silo a material is to be conveyed through FSC to a one station or in a process line but also FSC have a provision it can be coupled to the other station to convey the other material.

20+years of

Automating your bulk material transfer

Looking for something more?

Our Flexible Screw Conveyor can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USAdvantage:

- Due to their smaller diameter, smaller diameter conveyors have flexible casing and can be routed around stationary obstacles, unlike belt conveyors.

- In the case of conveyors, they can be shortened by simply cutting the casing and auger. They can be lengthened by substituting a longer section for the existing auger and casing.

- By removing the clean-out cap of a flexible screw, the screw can be quickly taken apart, disconnecting the bolts that attach the auger inside the pipe and sliding the auger out the bottom of the conveyor. The casing is removed by unbolting the couplings that hopper and discharge head is connected to it.

- Able to easily clean and easy maintenance of the shaftless screw conveyor by operating the screw in the opposite direction to remove residual material from the conveyor line.

Benefits:

- For accurate, economical and adaptable conveyor solution our screw conveyor

- Adds versatile flexibility to your plant.

- While conveying any material air is not used, only simple filters are needed at the destination points.

- Flexibility to route over plant obstructions hence ideal for unplanned brownfield requirements

- Economic & efficient transfer of material conveying solutions for powders, granules, and pallets.

- Increased production due to minimal requirement of manual handling

- Optional mobile systems for in-plant flexibility

Related Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry