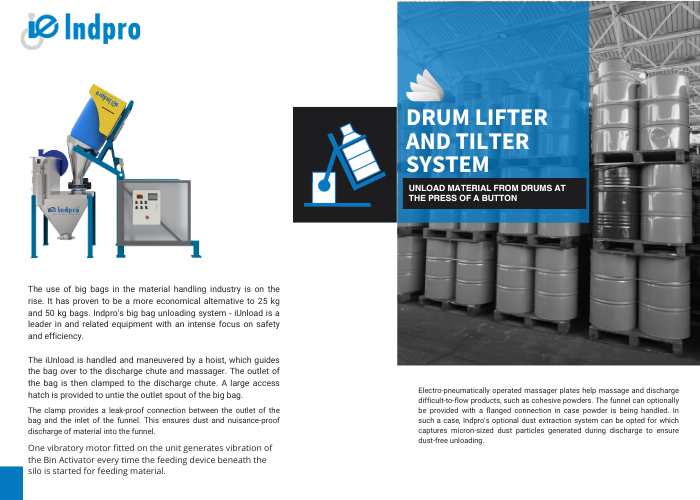

Drum Lifter And Tilter Systems:

Unload material from drums at the press of a button

Look no further for an efficient, safe, and dust-free solution for discharging material from drums in your industrial operations.

Raw material management in large industrial plants or warehouses often involves handling powders, granules stored in drums. These drums, typically ranging from 50 to 250 kg and made from materials such as plastic, steel, or fiber, are used for special-purpose substances. Moving and emptying these drums can be a challenge due to their weight and the materials they contain, whether it's powders, sticky substances, or hazardous chemicals.

Indpro’s Drum Lifter & Tilter Systems—available in both hydraulic and pneumatic versions—are designed to make material handling easy, safe, and efficient. These systems enable fast, controlled discharge of materials while ensuring dust containment and preventing spillage. The solutions are engineered to meet the specific needs of modern industrial processes by eliminating the manual effort involved in clamping, lifting, tilting, and discharging drums.

Indpro’s Hydraulic Drum Lifter & Tilter is ideal for handling heavier drums and materials

that require smooth and controlled operations. Equipped with robust hydraulic cylinders, this system ensures the safe lifting

and tilting of drums for precise discharge, making it a reliable choice for handling powders, liquids, or sticky

substances.

Indpro’s Pneumatic Drum Lifter & Tilter offers a lightweight and efficient solution for industries

dealing with bulk materials. Powered by high-quality pneumatic cylinders, it ensures fast and dust-free discharge, making it

perfect for handling lighter materials while maintaining complete containment and preventing dust

formation.

The design for our drum tilting system has carefully though of features. We have kept in

mind the practical challenges and constraints faced by operators who use our systems day in day out. Our systems

are designed to overcome these challenges and provide ergonomic and ease of use.

Our drum tilting

system can be easily integrated with any of our conveying equipment, such as pneumatic conveying system, powder

transfer system, flexible screw conveyor, tube chain conveyor, and many more.

Product Features

Advantage:

- Quick tilting of drum platform

- Airtight design prevents spills and dust leakage, ensuring a clean environment.

- Built-in controls and safety features allow operators to handle hazardous or heavy materials safely.

- Unloading a greater number of drums in minimal time

- Quick to dismantle and clean

- Low dependency on manpower

- Customizable to your specific industrial requirements.

20+years of

Automating your drum unloading

Looking for something more?

Our Drum Lifter And Tilter System can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT US| Features | Pneumatic Drum Lifter & Tilter | Hydraulic Drum Lifter & Tilter |

|---|---|---|

| Lifting Capacity | 50 to 150 kg | Up to 500 kg (customizable for higher loads) |

| Tilting Angle | Upto 150 degrees for complete material discharge | Upto 150 degrees for complete material discharge |

| Drum Sizes Supported | 50 to 150 liters | 50 to 350 liters |

| Operation Type | Pneumatic | Hydraulic |

| Operation Mode | By levers | By levers |

| Material of Construction of frame | MS / SS304 | MS / SS304 |

| Material of Construction of contact parts | MS / SS304 / SS316 / SS316L | MS / SS304 / SS316 / SS316L |

| Compressed Air Requirement | 5 bar(g) | Not Required |

| Applications | General industrial applications | Heavy-duty industrial applications |

| Maintenance | Minimal maintenance, air-powered components | Low maintenance with durable components |

| Pneumatic Hammer (Optional) | Yes, for sticky materials | Yes, for sticky materials |

Benefits:

- Lifetime warranty for frame

- Standard solution can cater to a wide variety of sizes of drums

- Includes straightforward controls that facilitate easy operation

- Features a smooth finish of parts that ensures no residual material after unloading

- Increases worker productivity and lowers production costs

- Drums with and without liner can be handled by this system

Applications:

- Vessel Charging

- Hopper Charging

- Reactor Charging

- Blender Charging

- Conveying System Charging

Related Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.