Jumbo Bag Unloading System

The use of big bags in material handling industry is on the rise. It has proved to be a more economical alternative to 25 kg and 50 kg bags. Indpro's big bag unloading system - iUnload is a leader in and related equipment with intense focus on safety and efficiency. Dust-free emptying, fast and secure handling and ergonomically designed for the emptying stations have a priority for this application.

Indpro’s jumbo bag unloading systems are specifically designed for discharging a large variety of products from different types of big bags. They eliminate dust emissions, product loss or product contamination. Several unique options are available for the safe and hygienic discharge of food ingredients, pharmaceutical products and toxic materials.

Our range is based on a simple modular structure, whereby the basic models can be

extended with several options to obtain a complete solution for discharging big bags also known as

big bag unloader. This modular range encompasses the discharge of single or multi-trip bags, with or

without a plastic liner. Indpro’s expertise in the application of the bulk bag unloading system has

proven reliability in practice with multiple successful installations. Our experience enables us to

cover various applications considering all customer specifications such as - type and nature of

product, type of bag, environmental aspects, system capacity, space limitations, etc.

Indpro supplies the jumbo bag discharge system and related equipment with an intensive focus to

provide safe, efficient, and complete bulk bag unloading and handling.

Product Features

Technical Specification

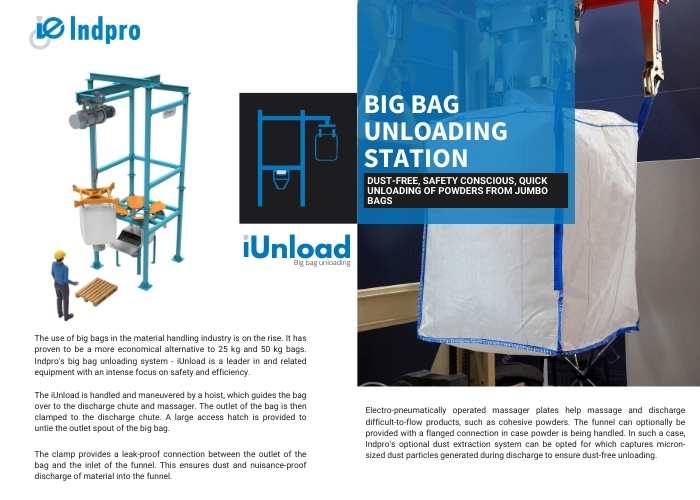

System consists of the following major components :

-

Big bag lift (hoist)

-

Bag holder

-

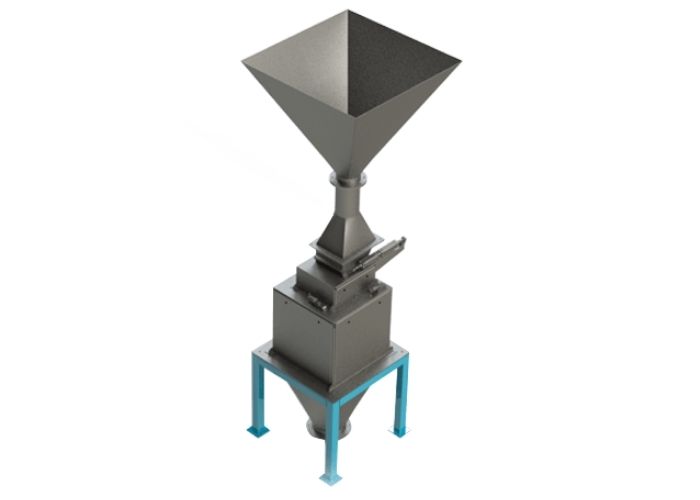

Discharge funnel

-

Bag massager

-

Discharge chute

-

Control valve – Iris / Slide gate

-

Sturdy metal frame to support the entire structure

-

Dust extraction system (optional)

20+years of

Automating your big bag handling

Looking for something more?

Our Jumbo Bag Unloading System can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USHOW BIG BAG UNLOADING SYSTEM WORKS?

Indpro’s iUnload is handled and maneuvered by a hoist, which guides the bag over to the discharge chute and massager. The outlet of the bag is then clamped to the discharge chute. A large access hatch is provided to untie the outlet spout of the big bag. The clamp provides a leak proof connection between the outlet of the bag and inlet of the funnel. This ensures dust and nuisance proof discharge of material into the funnel. Electro-pneumatically operated massager plates help massage and discharge difficult to flow products, such as cohesive powders. The funnel can optionally be provided with a flanged connection in case powder is being handled. In such case, a dust extraction system can also be provided which captures micron sized particles generated during discharge to ensure dust-free unloading.

EQUIPMENT FEATURES

Related Products

There are many more products and systems which you can explore

Big Bag Unloading System FAQ's

Big bags were formerly only used in a few industries (agricultural, chemical, pharmaceutical, polyolefin, polymer and other bulk material handling industries), and even then, only in limited quantities. They are also known as FIBC Jumbo Bags or Bulk Bags. They have now become the preferred choice for nearly every industry today that needs to store, pack and transport solid dry bulk materials. The salient features and advantages of shifting to big bags is their flexibility of use, space- and cost-saving qualities, weight carrying capacities, and ability to withstand tough conditions.

A bulk bag unloader is a special purpose machine designed to unload material from big or jumbo bags securely and efficiently. The bulk bag unloading system is also the first point of contact between your workers and your bulk powders and granules. As a result, the bulk bag unloader is where safe bulk material handling truly begins in your operation.

Even though big bags have been around for many years, much of the early bag-handling equipment was either poorly designed, home-built, or unsuitable for the job. However, injuries were uncommon due to infrequent use and small numbers. Injury rates have now began to rise as the equipment was put into increased service and workers were compelled to handle more bags with these sub-par systems. There are four types of injuries induced by the usage (or misuse) of bulk bags:

- During bag filling

- During bag unloading

- During bag lifting and shifting

- During bag storing or stacking

That is where our big bag unloading system comes in and helps you put a stop to all compromises. Our big bag unloading system has been built up using all safety standards. We have accounted for your working conditions, various mechanical and electronic locks, as well as alarm systems, to make unloading material from jumbo bags a hassle-free experience.

A Jumbo Bag Unloading System is a material handling solution that is designed to safely and efficiently unload bulk materials from large flexible containers, known as Jumbo Bags. The system typically consists of a frame or structure to support the Jumbo Bag, and a mechanism for emptying the material into a hopper or directly into a processing system.

Bag Size: The size of the Jumbo Bags to be unloaded should be considered, as this will determine the size and capacity of the unloading system.

Material Properties: The properties of the material to be unloaded, such as particle size, density, and flowability, should be considered to determine the type of unloading system and the components required.

Unloading Capacity: The desired unloading capacity should be considered, as this will determine the size and design of the unloading system.

Improved Safety: Jumbo Bag Unloading Systems reduce the risk of workplace accidents and injuries by eliminating the need for handling of the Jumbo Bags manually using forklift, EOT or chain pulley block.

Reduced Material Waste: Jumbo Bag Unloading Systems minimize the risk of material spillage and wastage, as the material is emptied directly into a hopper or processing system after being effectively clamped.

Increased Efficiency & Reduced Labor: Jumbo Bag Unloading Systems increase material handling efficiency by reducing the time and labor required for bag handling.

A Jumbo Bag is hooked onto a spider frame and positioned over the unloading system. Once the big bag is connected to the system, the material is emptied into a hopper or directly into a processing system. There is a set of massaging paddles that aids in effectively unloading the material. The material is then conveyed to a storage or processing system, either manually or using a conveying system.

Slip-resistant platforms: To ensure safe access to the Jumbo Bag, the unloading system may include slip-resistant platforms.

Dust extraction systems: To minimize the risk of dust explosions, the unloading system may include a dust extraction system to capture and remove airborne dust particles.

Emergency stop buttons: To ensure the safe operation of the unloading system, emergency stop buttons may be included to quickly stop the system in the event of an emergency.

Safety guards: To protect workers from moving parts and materials, the unloading system may include safety guards to prevent access to dangerous areas.

Want to know more about the big bag unloading system?

Tell us more about your application needs.

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry