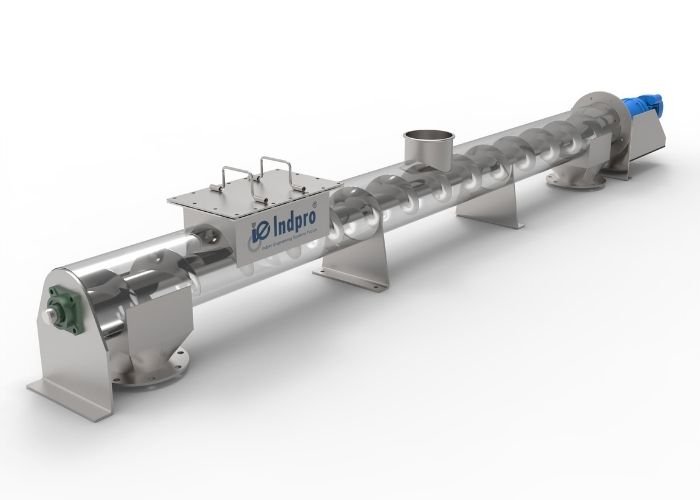

Spent Grain Conveyor

Indpro’s wet spent grain conveyors – iExpel are simple yet efficient systems that help you get rid of your wet spent grain that is left over after the brewing process. These systems meet today’s demands for operational safety, low air consumption, easy cleaning and maintenance. Indpro, based on decades of experience, has configured standardized models to choose from. Our offerings can cater to most of brew lengths of modern commercial breweries. Our spent grain conveyor can also be used in various other industries, where a mass with high moisture content (wet cake) is to be transferred, industries such as food processing, for applications like, various sauces manufacturing, shrimp processing etc.

Spent grain conveyor - iExpel is placed under the lauter tun/mash filter in the brew house. The mass enters the trough through the storage bin/chute which is compressed by variable flight screw conveyor. The de-watering arrangement is provided below the screw to drain the wastewater. The conveying screw pushes the mass through the non-return valve to the conveyor outlet. This region is pressurized by the compressed air/steam connection. The spent grains are conveyed pneumatically in a plug-conveying operation. Thus, spent grains, a by-product of the brewing process, are conveyed to a wet spent grains distribution plant (silo). Indpro’s spent grain conveyor - iExpel offers a simple, quiet and efficient way to convey wastewater spent grain, from the lauter tun to the spent grain silo.

Product Features

Technical Specification

-

Throughput capacity

Up to 20 tons per hour

-

Motor

22 kW

-

Surface finish

Powder-coated

-

MOC

Mild steel (painted or galvanised)

Stainless steel

20+years of

Automating your grain transfer

Looking for something more?

Our Spent Grain Conveyor can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USRelated Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.