Solutions For Plastic & Polymer

The recent trend of replacing metallic parts with engineering plastics, increase in various types of electronic gadgets & packaging concepts has fueled the consumption of plastic as a raw material. To match this development for industries in compounding & master batches, we offer following solutions:

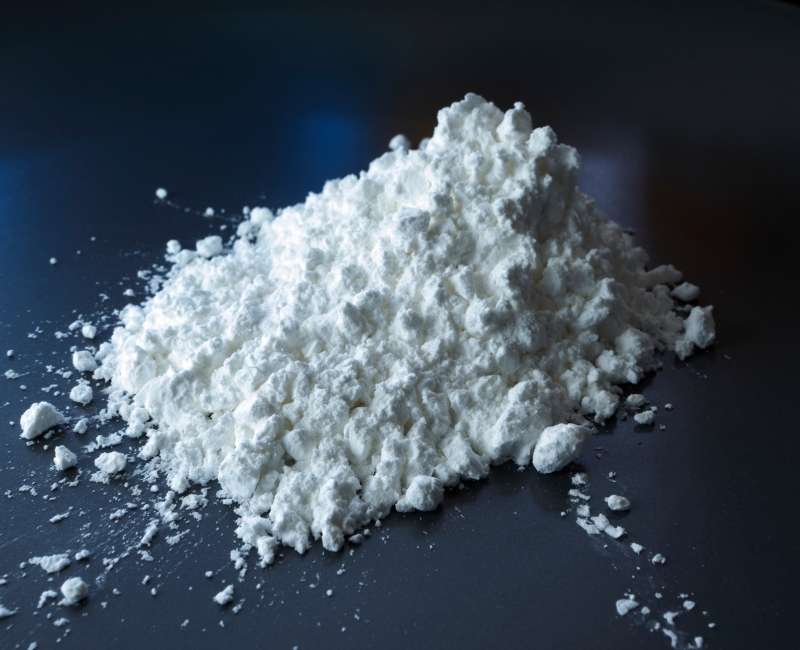

- Combination of mechanical & pneumatic conveying of raw material (calcium carbonate, talc, polymers, resins, various additives etc.) from its receipt till extruder feed

- Blending of different polymer grades

- Pneumatic conveying of finished product to storage silo

- De-duster for removal of fines & streamers, generated due to conveying, from finished products before packing

- Bagging & pelletizing solutions for finished products

Solutions offered to plastic industry

Use of plastics have risen significantly across multiple sectors and have more applications in today’s day and age as compared to ever before. Usage of plastic as a raw material has been driven by the current trend of replacing metallic parts with engineered plastics, as well as a growth in various sorts of electronic devices and packaging designs. To keep up with this trend in the compounding and master batch sectors. Increased requirement of production gives rise to the need for automation in production aspects. Material handling in the Plastic & Polymer industry plays a vital role in nearly all aspects of the process, from raw materials handling and manufacturing to distribution and consumption. Reliable bulk material handling is critical for achieving six-sigma operations, process automation, lean production, efficiency optimization, and debottlenecking. Poor flow is a problem with base fluff, resin, pellets, pastille, and granule polymer forms. Blocking, sticking, unpredictable flow, uneven discharge, segregation, ineffective mixing, and a lack of first-in, first-out vessel discharge sequence are all examples of flow difficulties. Material stagnation in storage bins, pellet degradation (fines formation), and batch cross-contamination can all cause product quality issues. Snake skins, streamers, and angel hair are all common by products of pneumatic conveying of plastics, all of which can clog downstream equipment. Increase your productivity and efficiency with our innovative products and solutions for your plant, whether you're handling a new resin with sticky qualities, feeding compounded plastics to an extruder or pelletizer, or driving off volatiles in a purge vessel, Indpro can assist you in achieving consistent material flow and higher throughputs.

Indpro Engineering Systems Pvt. Ltd.

Expertise that enables us to solve even the most challenging of dry plastics & polymer handling issues.

Industries we cater to

Challenges & Solutions

Handling different materials has it challenges, and we have the right solutions to cater to them

Raw Material Unloading

Is done through several equipment such as Bag Dump Station, Big Bag Unloading Station and Automatic Bag Emptying Machine.

Pneumatic Conveying System

Is used for transferring material from point A to point B for plastic & polymer using high levels of flexibility. These are practically maintenance free devices.

Storage Silos & Hoppers

Are required for storing powders before sending them to the process area. Weighing makes sure right amount of powders are consumed.

Drying & Blending

iBlend is used for the blending polymer manufactured in various batches. While taking care of the blending, the polymer granules are simultaneously dried with hot air.

Filtration Systems

Are used as dust collectors to separate dust particulates from dusty gases and keep

the process area free of dust.

Ribbon Blenders & Horizontal Blenders

Are used for the blending of different types of chemical products. Variety of grades of chemicals can be homogenized using our blending solutions.

Bagging Machines

Allows to automatically weigh and fill powders, granules, flakes, fibrous materials and large particles into various sizes of bags, ranging from 25 kg bags to jumbo bags.

What people are saying about Indpro

An honest endorsement from our satisfied clients will help you understand how our services have made a difference in their businesses and are ready to make in yours.

Partnering with Indpro was a game-changer for us. As a manufacturer of cable compounds, there is a huge variety of powders and polymer granules used in our process. A dependable bulk material handling system is crucial. The system comprised of jumbo bag handling, small bag dumping, and conveying to the extruder while controlling any dust present in the system. They helped not only improve our operational efficiency but also elevated the quality of our products. Their team's expertise and prompt support reflect their dedication to delivering excellence.

Kaushik Naik

DDev Plastiks Industries Ltd.

We have been in the polymer industry for decades, and Indpro’s conveying system to silos is a great investment we have made. Their conveying system ensures that plastic granules are handled with consistency. It's a pleasure working with a company that understands our unique needs.

R S Negi

Chiripal Poly Films Ltd.

We have been associated with Indpro since 2017 and have implemented numerous conveying systems for various grades of polymers. Their system has streamlined our bulk polymer handling process, saving us both time and resources. The seamless integration and user-friendly interface make it an essential asset for any production setup.

Shantanu Majumdar

Jindal Poly Films Ltd.

The automation and efficiency offered by Indpro's systems have elevated our raw material & finish good products handling process. We have partnered with them for multiple extrusion lines. We handle multiple raw material grades using jumbo bags and small bags. We are highly satisfied with the performance and reliability of their systems.

Varun Gupta

Calco Poly Technik Pvt. Ltd.

Indpro has helped us with improving the capacity of our existing conveying system at an optimal cost. Their understanding of our process and quick responses helped us complete the enhancement project in a short period. The engineering team promptly visited our factory and studied the process and offered their solution. We are happy with the services provided by them and recommend them to anyone looking to enhance their conveying systems.

Jigar Trivedi

Sabic Innovative Plastics

We're delighted with the performance of Indpro's conveying system. They have delivered the promised specifications within a challenging timeframe. The system's robustness and reliability for handling polymer granules at high capacity has helped us enhance our existing processes. Their commitment to delivering a reliable product is evident in every aspect of their system.

Sanjeev Mohite

Lanxess India Pvt. Ltd.

Indpro has automated material handling for polymer and fine powders at our plant for both lines. We have been using the system for over 6 years. The genius of their design is the ease of maintenance, uninterrupted service, and safe operation for everyday use. The complete experience of working with Indpro team has been a delight especially in the recent years after Rounak has joined the business. It has helped me deliver quality products with repeatability to my customers! I recommend Indpro for top quality bulk material handling equipment.