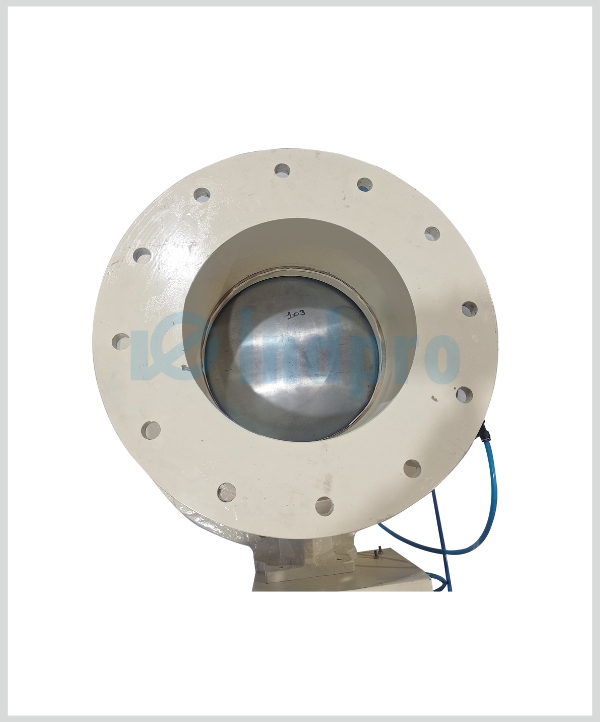

Dome Valve

Reliable Sealing Solution for High-Pressure Conveying of Bulk Solids

What is a Dome Valve?

A Dome Valve is a highly efficient, robust, and leak-proof valve designed specifically for bulk material handling applications, particularly in pneumatic conveying systems. It features a unique hemispherical dome-shaped mechanism that ensures a full-bore flow path, allowing unobstructed movement of powders, granules, or other bulk solids.

What sets the dome valve apart is its ability to close and seal against pressure of flowing or static materials, making it ideal for applications involving high-pressure differential and abrasive materials. Dome valves are commonly used in dense phase pneumatic conveying systems for feeding or discharging materials between pressure vessels and pipelines.

At Indpro, we understand the critical role valves play in the reliability and efficiency of pneumatic conveying systems. That’s why our Dome Valves are engineered in-house with precision, durability, and application flexibility in mind.

Our dome valve is not just a standard component – it's a custom-engineered solution designed to handle even the most abrasive, cohesive, or sensitive materials in high-pressure conveying environments.

Key Features:

Advantages:

- Reliable Sealing under Pressure – Maintains system pressure integrity during conveying

- Prevents Material Leakage – Minimizes product loss and dusting

- Handles Tough Applications – Effective even in the presence of sticky or abrasive materials

- Smooth Integration – Easily fits into existing pneumatic conveying lines or silo systems

- Increased System Efficiency – Reduces downtime and ensures consistent material flow

- Minimal Downtime – Quick access to internals for inspection and service

Applications:

- Dense Phase Pneumatic Conveying

- Pressure Vessels and Feeders

- Reactor Discharge Systems

- Silo Outlet and Hopper Interfaces

- Chemical, Mineral and Cement Industriess

- Fast Operation – Quick actuation ensures smooth material transfer

20+years of

Automating your bulk material flow

Looking for something more?

Our dome valve can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USRelated Products

There are many more products and systems which you can explore

Frequently Asked Questions (FAQs)

To choose the right dome valve, consider your material type (abrasive, powdery, sticky), operating pressure and temperature, valve size, and flow rate. Dome valves are ideal for dense phase pneumatic conveying and high-pressure systems due to their wear-free sealing and zero-leakage design. Select the material of construction based on your industry—stainless steel for food/pharma or cast iron for industrial use. For best results, consult a reliable bulk material handling expert like Indpro.

Dome Diverter Valves require minimal maintenance due to their robust and wear-free inflatable seal design. Regular checks should include inspecting the inflatable seal for wear or leaks, verifying smooth dome movement, and cleaning any material buildup. Periodic lubrication of moving parts and checking pneumatic connections also help ensure optimal performance. With proper maintenance, Dome Diverter Valves offer long-lasting, leak-proof, and low-maintenance operation—ideal for pneumatic conveying systems and bulk material handling applications.

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.