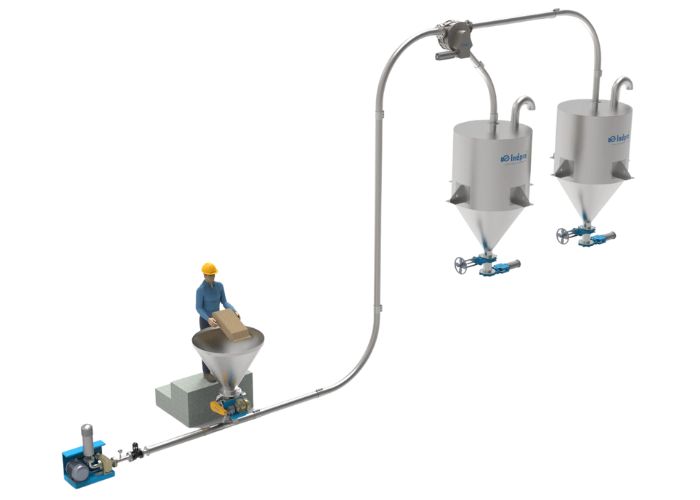

Drum Unloading System

Efficiently transfer materials from drums to downstream processing with ease

Indpro’s drum unloading system was developed to well integrate our conveying systems with drums to avoid material dusting at the source and ensure no contamination in the product being handled.

Why is this so significant? Because we view this as one of the most difficult aspects of the food, chemical, agrochemical, and pharmaceutical industries. Contamination in the product at the unloading point leads to various troubles in the manufacturing process or in the quality of the final product.

This space-saving device offers high versatility to work with different drum heights and diameters under inert atmosphere, if required. drum unloading system is extremely cost-effective when compared to conventional isolation systems.

Safety is always a top priority, thus no drum lifting or tipping is necessary even when there is a chance of a partial drum emptying.

There are numerous materials accessible for whole system integration (SS304, SS316, SS316L).

Our DIS also manages to integrate to different sizes and types of drums, including plastic or steel drums and

cardboard bins.

The drum integration station with suction lance offers the perfect solution in combination with the

pneumatic vacuum conveying system. The system is optionally adaptable for a large variety of tasks; therefore,

different designs are possible according to the GMP guideline in conformity with FDA or ATEX standards.

A loss in weight dosing and the weighing unit can be integrated to enable a partial or complete drum discharge.

Working of drum unloading system:

Options

-

Load cells for accurate dosing

-

Inert operation

-

Platform for small drums

-

Possibility for sampling

20+years of

Automating your bulk material transfer

Looking for something more?

Our Drum Unloading System can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USAdvantage:

- Emptying double-lined drums of various sizes without contamination.

- Use the Powder Transfer System or Vacuum Conveying System in conjunction.

- No lifting or tipping of drums is necessary.

- Maximum visibility within the drum.

- Space saving.

- Partial emptying possible.

- Simple to install and easy to clean

- GMP compliant.

Related Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry