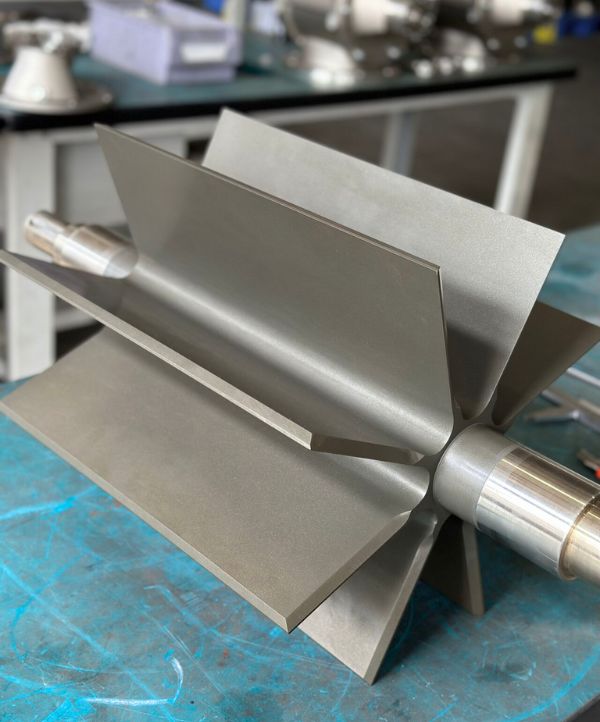

Fall Through Rotary Air Lock Valve

Indpro, the leading manufacturer of rotary air lock valves in India, dedicated to providing high-quality, reliable, and efficient products. Our fall-through rotary airlock valve is specifically designed to meet the unique needs of various industries, including food processing, chemical, minerals, and plastics, to name a few.

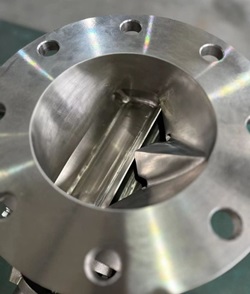

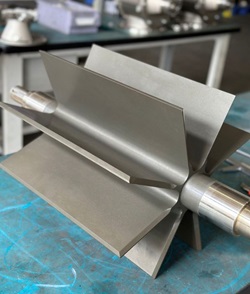

Our rotary airlock valve is designed to provide both feeding and metering function. However, it is primarily used to differentiate pressurized and non-pressurized regions by creating an optimal airlock seal during the transfer of different products at a controlled feedrate. With radial and axial clearances ranging between 0.1 to 0.2 mm, these valves ensure minimal air leakage from the axial and radial gap, hence preventing air pressure loss in high-pressure conveying systems.

The rotor is designed with 8 to 10 vanes and is driven by a geared motor, ensuring a consistent and reliable performance. The design of our rotary airlock valve includes a circular end connection, a cast iron or stainless steel casing, a horizontally mounted rotor-vane assembly, a drive unit, and a casing cover opposite the drive end.

There are options for either direct drive connection or chain drive connection. This design allows for precise

control of the discharge and feed of powder or granular materials from silos, hoppers, bag filter houses, or

cyclones to pneumatic conveying lines.

We understand that different industries have unique needs when it comes to product metering, which is why we offer

specialized designs for fine product metering into your process application. There are various designs we execute

with the rotor and stator for taking care of different applications. At our company, we understand that every

customer has unique needs, which is why our team of seasoned engineers collaborate closely with each client to

develop customized solutions that precisely address their specific requirements.

At Indpro, we are committed to providing our customers with high-quality rotary airlock feeders that offer optimal

performance and precision. With our drop-through rotary airlock valve, you can expect reliable and efficient

performance, ensuring your production process runs smoothly and efficiently. Contact us today to learn more about

our rotary airlock valve solutions and how they can optimize your bulk material handling needs.

Product Features

Related Products

There are many more products and systems which you can explore

Rotary Airlock Valve FAQ's

The size of rotary airlock valve to be selected depends on several factors, including the flow rate, pressure drop, material properties of the powder or granules being handled and many more. It is important to consult with our expert to determine the right size for your application.

Maintenance of a rotary airlock valve includes regular inspection, cleaning, checking for proper operation and wear of the rotor, lubrication of the bearing surfaces and condition of the sealing mechanism. It is important to follow the manufacturer's recommendations for maintenance to ensure proper operation and longevity of the valve.

Common problems with rotary airlock valves include wear and tear, clogging, and material build-up in the rotor pockets, seal leakages and bearing failures. To fix these problems, the valve should be cleaned and inspected, and any worn or damaged parts should be replaced.

Industry standards for rotary airlock valves vary by application and industry, but some common standards include ASTM and ISO specifications for materials, dimensions, and performance. It is important to consult with our expert and follow the relevant industry standards for your application.

Indpro

Typically replies within an hour

Send Enquiry