Specialty Filter - Industrial Dust Extraction System

The right filter for every conceivable dedusting

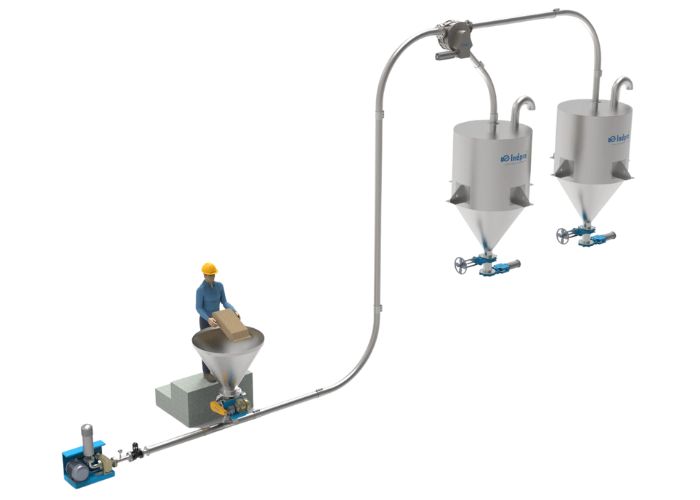

Specialised filter - Industrial dust extraction system from Indpro extract airborne contaminants in, filtering it of particles before releasing the purified air. Dust collectors manufactured by Indpro are used extensively in process industries, especially for chemical processing, plastic processing, food processing, and pharmaceuticals. Dust collectors come in a variety of designs depending on their intended function, but they all have four basic components in common: a blower to collect and circulate/evacuate air, a filter to remove pollutants, and a bin to collect dust for disposal and interconnecting piping between all equipment. Dust collectors not only help businesses satisfy air quality standards, but they also boost productivity and profitability by shielding equipment and people in the production area from harmful dust emissions.

Product Features

Construction:

- The clean gas segment and the dirt gas section are separated by a filter mounting plate in the entire mechanical assembly.

- A hopper with a filtered dust discharge system is included in the raw gas side casing, which also contains the filter components.

- The clean gas section contains a set of blow tubes that are connected to a set of pulse valves and a compressed air manifold on the outside.

- Available in MS, SS304, SS304L, SS316 & SS316L construction.

- Easy removal of bag / cartridge from the top or side.

- Available both in rectangular & cylindrical configurations.

- Single & multi compartmental construction considering the capacity & on-line maintenance requirements.

- Housing is designed as per process pressure requirement, can be suitable for -1 bar (g) (full vacuum) to 1 bar(g) (pressure).

- Suitable designs are available for explosive dusts. Compatibility in terms of installation of explosion vents is possible.

20+years of

Automating your dust collection

Looking for something more?

Our Specialty Filter can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USTypes of filter elements in specialized dust collectors

Related Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.