Pneumatic Bulker Unloading

& Storage System

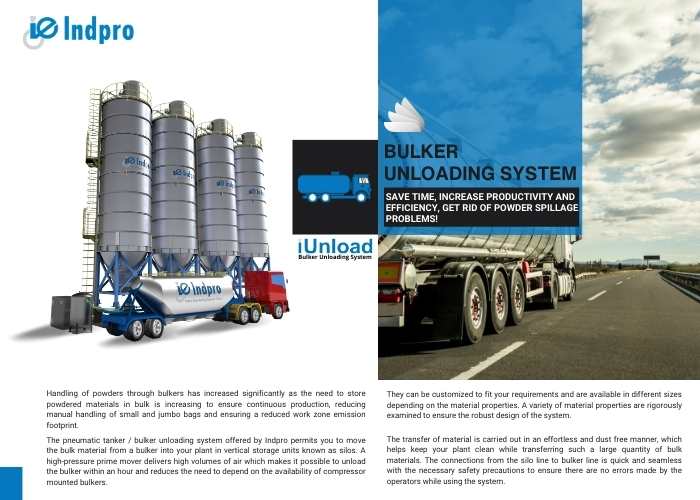

Save Time, Increase Productivity and Efficiency, get rid of powder spillage problems!.

Handling of powders in bulkers has been expanded significantly as the need to store powder materials in bulk is increasing to ensure continuous production, reduce manual handling of small and jumbo bags and ensure a reduced work zone emission footprint. This has led to a need for unloading materials from powder tankers/bulkers efficiently and safely.

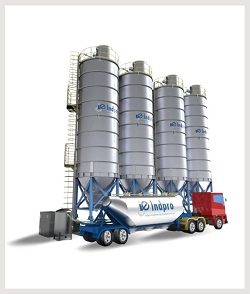

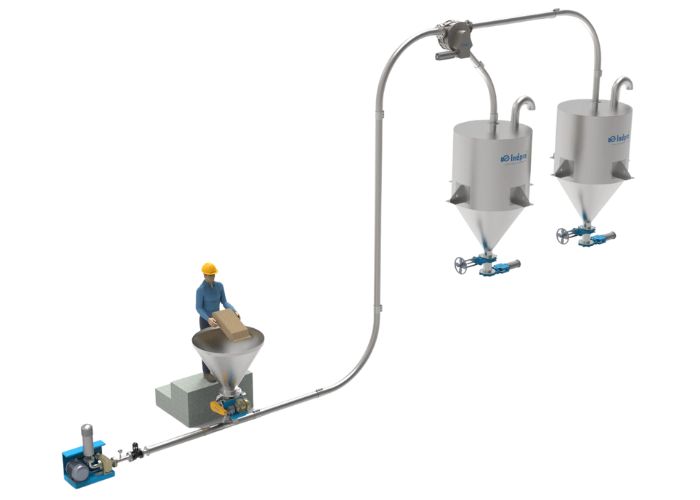

The pneumatic tanker/bulker unloading system offered by Indpro permit you to move the bulk material from a bulker into a silo or hopper to store it your plant. A high-pressure prime mover delivers high volumes of air which makes it possible to unload the bulker within an hour and reduces the need to depend on the availability of compressor mounted bulkers. They can be customized to fit your requirements and are available in different sizes depending on the material properties. A variety of quality parameters are rigorously examined to ensure the quality of the system.

This system transfers powder directly from tankers/bulkers to

storage silos. There are tanker/bulker unloading pneumatic conveying systems that range in rate from 10 to 25 TPH (tonnes per hour), the unloading

process varies according to the material.

The transfer of material is carried out in an effortless and dust free manner, which helps keep your plant clean

while transferring such a large quantity of bulk materials.

Product Features

Benefits

- Reduction in labour, packing and transportation cost

- Lower dependency on unskilled labour to move bags in the plant

- Better space utilization due to smaller material storage footprint

- Faster and more efficient unloading of bulk material

- Avoid dust generation and maintain plant cleanliness and hygiene

- Reduces losses of bulk material as the loss rate of powder by tanker transport is about 0.5%, whereas it is about 2.5~5% by bags

Materials handled

- Soda ash, Dolomite, Calcium Carbonate

- Talc, Calcined clay, Sodium Sulphate

- Bright calcite, Cement,Soda speckles, Wheat flour

20+years of

Automating your bulker unloading and storage system

Looking for something more?

Our Bulker Unloading System and Storage System can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USRelated Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry