Blow Through Rotary Airlock Valve

Indpro is the leading manufacturer of high-quality blow-through rotary airlock valves designed to handle a wide range of materials in various applications. Our blow-through variant is a versatile tool that is specifically designed to provide an optimal airlock seal between pressurized and non-pressurized regions, making it ideal for cohesive powders.

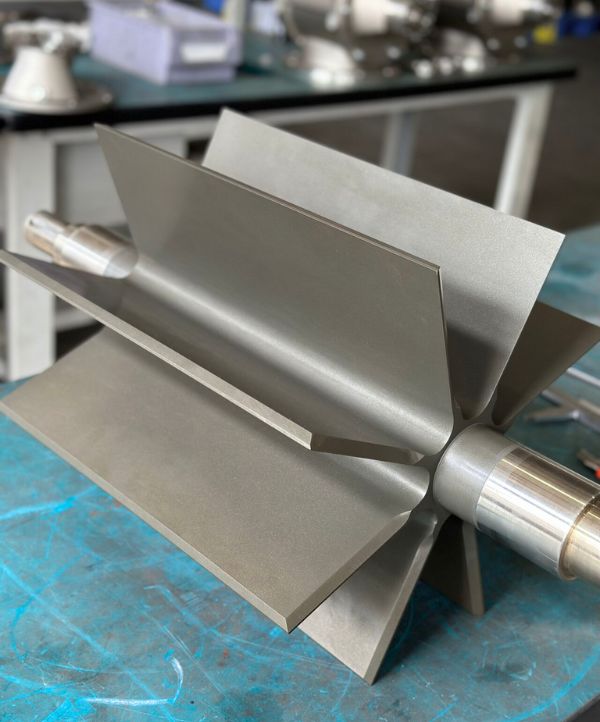

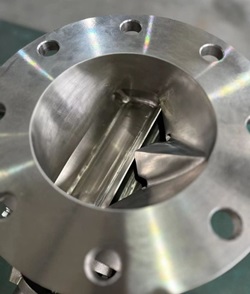

With radial and axial clearances between 0.13 to 0.20 mm, our blow-through rotary airlock valve utilizes high-pressure air to clear the rotor vane pockets, ensuring smooth and efficient operation. The valve is also ideal for controlled feed of powders from silos, hoppers, bag filter houses, or cyclones to pneumatic conveying lines.

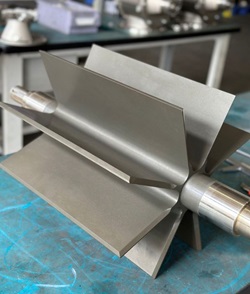

At the core of our pneumatic conveying technology is the precision-engineered rotary airlock valve, incorporating a circular end connection for seamless integration, a robust cast iron or corrosion-resistant stainless steel casing, and a precisely aligned horizontal rotor-vane assembly that ensures optimal performance and reliability.

The drive unit is on one side of the opening; opposite it is an external cover that houses components such as gearboxes and

reducers. With 8 to 10 vanes driven by a geared motor, our rotary airlock valve is a reliable and efficient solution

for your material handling needs.

At Indpro, we are committed to providing high-quality products and exceptional customer service. Our team of experts

is always ready to assist you in selecting the right blow-through rotary airlock valve for your specific

application. We take pride in our products and are dedicated to delivering the best value to our customers.

Our blow-through rotary airlock valve is the ideal solution for those looking to improve their material handling

process. Contact us today to learn more about our rotary airlock valve and how we can help you achieve your material

handling goals.

Product Features

Advantages

- Lesser head room is required

- Precision machined to actual operating temperatures for a tight seal

- Outboard mounted, maintenance-free bearings

- Conveying line adapters and pocket venting options

- Custom side seals and air purging for longer shaft seal life

20+years of

Automating your control feed

Looking for something more?

Our Rotary Air Lock Valve can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USRelated Products

There are many more products and systems which you can explore

Rotary Airlock Valve FAQ's

A rotary airlock valve is used to regulate the flow of material being conveyed. The valve is typically positioned at the point where material enters or exits a storage vessel or process equipment. The internal rotor has a series of pockets that continuously fill and discharge the material while maintaining a minimal clearance to prevent air or gas from entering or escaping. The rotary airlock valve helps to regulate the flow of material in the pneumatic conveying system, ensuring consistent and efficient transport of the material. A rotary airlock valve is a compact and robust solution for metering feed rate of material passing while maintain a differential pressure across the device.

Rotary airlock valves can be made of a variety of materials, including carbon steel, stainless steel, and cast iron, with various types of tips including PTFE, PU, hardened steel, etc. depending on the specific requirements of the application.

Rotary airlock valves are widely used in industries such as plastic, polymer, food processing, pharmaceuticals, chemicals, and minerals, where they are used to control the flow of powders, granules, and bulk materials.

Rotary airlock valves come in various types depending on the application they serve. Most common differentiation between types include fall through and blow through. There are various add on features available such as quick cleaning arrangement, air venting arrangement, shaft seal purging arrangement and many more. Rotors also come in a variety of choices such as open ended, closed ended, with different type of adjustable tips, and many more.

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry