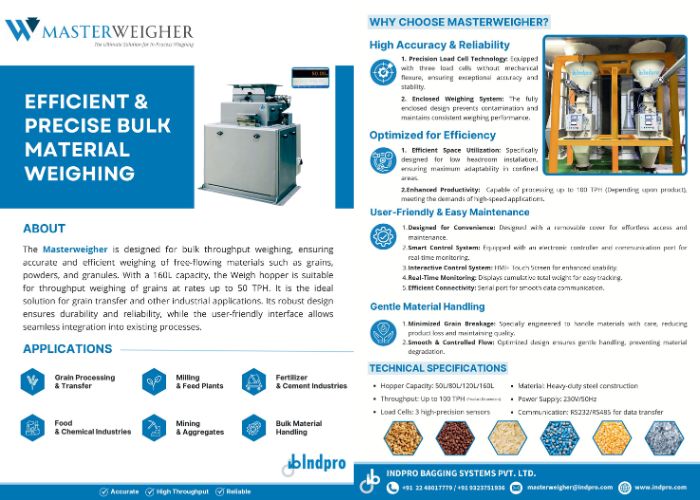

MasterWeigher®- Bulk Material Weighing Systems

The MasterWeigher is designed for bulk throughput weighing, ensuring accurate and efficient weighing of free-flowing materials such as grains, powders, and granules. Designed for industries demanding high throughput and accuracy, this robust system combines a 160L capacity hopper with throughput rates up to 50 TPH (product-dependent), ensuring seamless integration into your operations. Its heavy-duty steel construction and intuitive user-friendly controls make it the ultimate solution in grain transfer, industrial processing, and beyond.

Whether you’re transferring grain into silos, managing material batches, or optimizing food production lines, the MasterWeigher is engineered to elevate your operations while minimizing waste, downtime, and product loss.

The Challenge in Bulk Weighing

Industrial operations demand equipment that can keep pace with high-volume workflows without sacrificing accuracy. Traditional weighing systems often struggle with inconsistent measurements, material contamination, or mechanical wear, leading to costly errors, compliance risks, and operational bottlenecks. Add confined spaces, harsh environments, or sensitive materials to the mix, and the need for a smarter, sturdier solution becomes clear.

Industries We Serve

Technical Specifications

20+years of

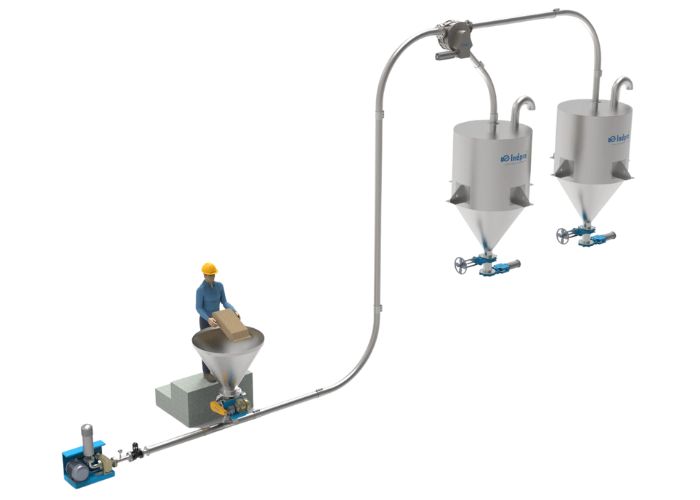

Automating your Bulk Inline Weighing system

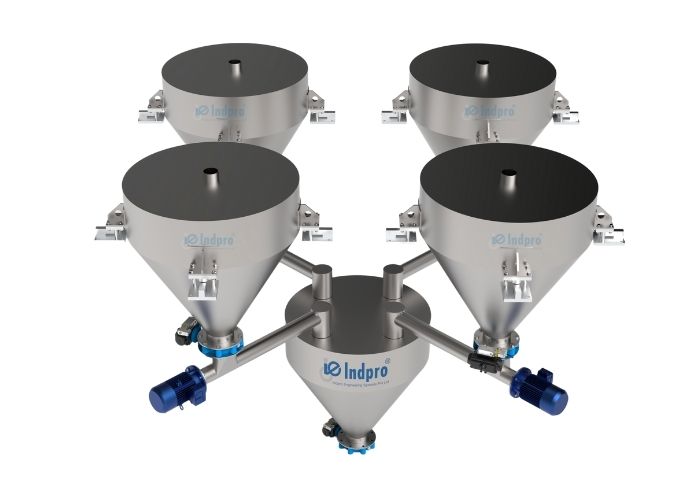

Looking for something more?

Our PelletPurge® can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USWhy Choose the MasterWeigher?

1. Unmatched Accuracy & Reliability

- Precision Load Cells: Three high-precision sensors eliminate mechanical flexure, delivering ±0.1% accuracy.

- Fully Enclosed Design: Protects against dust and contamination while ensuring stable performance.

- Heavy-Duty Steel Construction: Built to withstand demanding industrial environments.

2. User-Friendly Operation & Maintenance

- Smart HMI Touch Screen: Intuitive interface for real-time monitoring of cumulative weights and system diagnostics.

- Removable Access Panels: Simplify cleaning and maintenance downtime.

- Seamless Connectivity: RS232/RS485 ports enable integration with PLCs, ERP systems, or IoT platforms.

3. Optimized for Maximum Efficiency

- Space-Saving Design: Low headroom installation adapts to confined spaces without compromising capacity.

- High-Speed Throughput: Process up to 100 TPH* (*varies by material) to meet tight production schedules.

4. Gentle Material Handling

- Minimal Product Breakage: Specially engineered to handle materials with care, reducing product loss & maintaining quality

- Smooth Discharge: Optimized design ensures gentle handling, preventing material degradation.