Herding Filter

Dust collectors have a wide range of applications, and every process industry is using dust collectors in some form or other. Indpro in association with Herding GmbH are pleased to offer a revolutionary sintered plate filter element-based pulse jet filter used to separate dust particulates from fugitive dust emitting sources & process off gas. This filter ensures specialized filtration technology which provides better performance in terms of lesser emissions & longer element life as compared to traditional filters.

Herding dust collecting systems have special designs to protect personnel and machinery. They help protect the environment and recover valuable material from the process.

These special patented sinter-plate filter media and complete standard systems or customized solutions are manufactured in Herding, Germany. The hot gas filter media and systems cover a temperature range of up to 450° C. The maximum pressure range for process filters can extend from vacuum to a pressure of 10 bar(g). Special solutions for hazardous dusts and gases are available depending on the application.

Depending on the requirements, our system solutions start with collection of the dust and end with its

removal. A suitable controller rounds out such a system solution into a fully automatic and low-maintenance

solution, particularly since the filter media have an extremely long service life. These elements are ideal for

product recovery due to their nature of filtration. There is no contamination that passes from filters to the dust

being recovered.

Our products are supplemented by a wide range of accessories such as automatic pre-coaters to ensure that our

systems run without problems. Extensive services including trainings for our customers' service and maintenance

crews complete our range of products.

Product Description

With a system solution, we collect the dust, transport it to filters, separate it and pack it for disposal, recycling or reusing. The system thus consists of

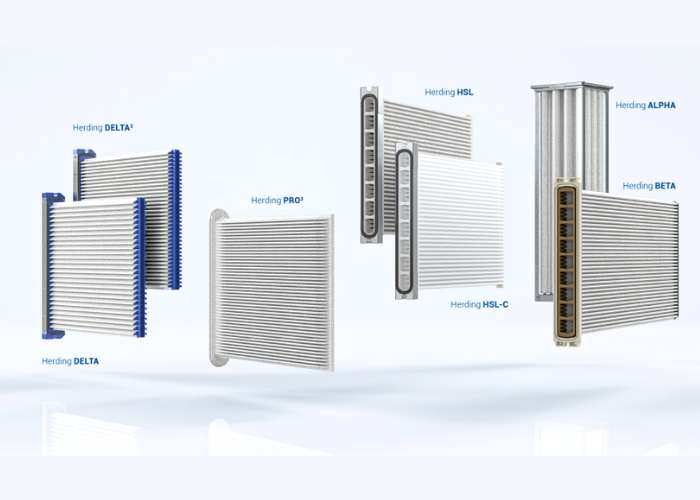

Available Filter Media Units

-

HSL up to 70°C/158°F

-

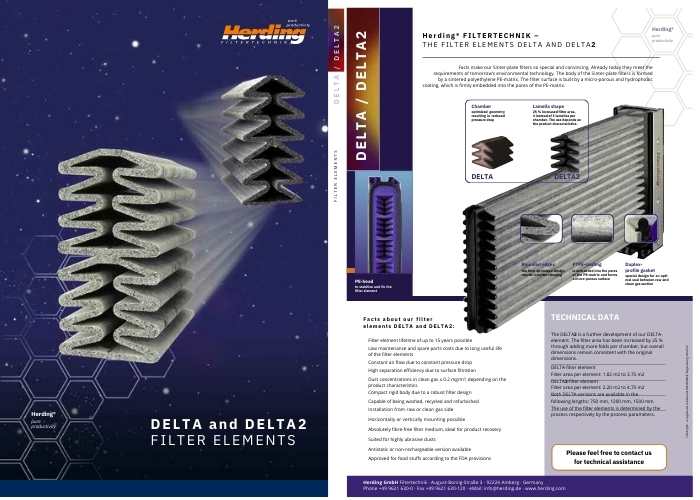

Herding DELTA/DELTA² up to 70°C/158°F

-

HSL-C Filters up to 100°C/212°Fs

-

Herding ALPHA Filters up to 450°C / 842°F

20+years of

Automating your dust collection

Looking for something more?

Our Herding Filter can very well be integrated with other system solutions we offer. You can speak with our experts to know more about how we can integrate it with our Pneumatic Conveying Systems, Air Pollution Control Systems or Bulk Solids Handling Systems.

CONTACT USFeatures:

- They have a feature of continuous operation with a built-in facility for automatic regeneration of filter elements by compressed air without system shut down

- This cleaning process is controlled through an electronic timer in DP mode or pre-set mode

- They are the most efficient solution, capable of achieving emission levels as low as 0.1 mg/Nm3, with a filtration equivalence HEPA E-11, having FDA approval ideal for product recovery

- The filtration mode is “Surface Filtration” due to PTFE coating on filtration side enabling a constant air flow & pressure drop conditions

- Expected filter life of several years and compact overall construction are the hallmarks of our product range

- These filters are customized & can be designed for handling normal & explosive dusts

- Medium like hybrid mixtures of explosive gas with explosive dusts can also be handled with constructive protection measures & several special safety features

- We have offered high pressure, CIP (Cleaning in place), sanitary finish specialty filtration solutions to various industrial demands / applications

Specifications:

- The complete mechanical assembly consists of dirty gas section & clean gas section divided by a filter mounting plate

- Dirty gas section comprises a casing which houses filter elements & hopper with a filtered dust discharge device

- The clean gas section houses assembly of blow tubes which are connected externally to an assembly of pulse valve & compressed air manifold

Related Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry