Plastic Resins Conveying Systems

The plastics industry plays a pivotal role in our modern world, with plastic resins serving as the foundation for a wide range of products we use daily. To ensure efficient production and handling of plastic pellets, pneumatic conveying systems have become an essential system solution for current manufacturing processes. We will explore the key features of plastic resins conveying systems, discuss the challenges they face, and provide solutions to address these issues. Additionally, we will answer some fundamental questions related to plastic pellets and conveying systems.

What is Plastic Resin?

Plastic resin is a fundamental raw material in the plastics industry. It is a polymer compound that, when heated and molded, can be shaped into various plastic products. Plastic resins are used in countless applications, including packaging, automotive components, medical devices, toys, and more.

Key Features of Plastic Resins Conveying Systems

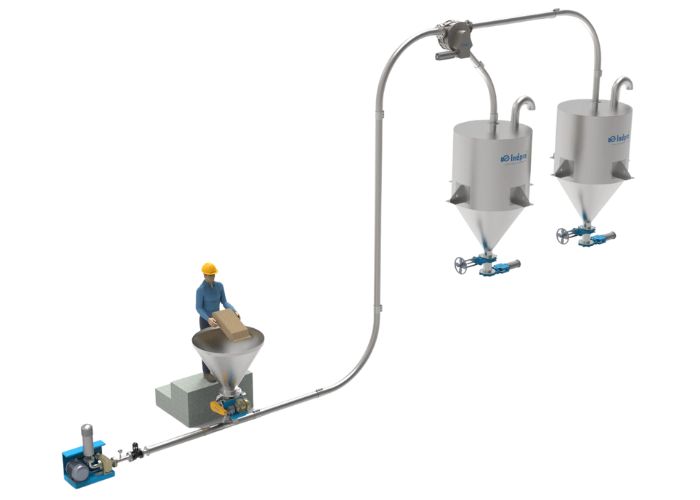

Raw material handling

Plastic pellets or granules are often sensitive to temperature, humidity, and shear forces. Conveying systems are designed to handle these materials with care, ensuring that they reach their destination intact and without degradation.

Dust Control

While conveying a material to the dedicated destination point, at the discharge point, with material dust may come which tends to harm the material quality. To minimize this, our effective online dust control system gives you a satisfactory result which incorporate dust control mechanisms to minimize the release of fine particles into the environment, ensuring a cleaner and safer workplace.

Energy Efficiency

pneumatic conveying systems are designed with energy-efficient features to reduce operating costs and environmental impact. These systems often incorporate variable speed drives and optimized routing.

Challenges and Solutions

Material Degradation

One of the primary challenges in plastic resin conveying is preventing material degradation due to excessive heat or shear forces during transport of mechanical handling. The solution lies in using conveying systems with precise temperature and velocity controls to maintain material integrity.

Contamination and Cross-Contamination

Contamination is a significant concern, as even small impurities can affect the quality of plastic products. Employing closed-loop conveying systems and incorporating inline filters can help prevent contamination.

Benefits of Pneumatic Conveying System

Pneumatic conveying plays a significant role in the transportation of resin materials within the plastics industry. This method of conveying uses air pressure to move resin materials through a network of pipes or tubes, offering several advantages and functionalities in resin conveying:

Related Products

There are many more products and systems which you can explore

Latest blog post

We would love for you to know more about what goes behind designing of our systems and our considerations for the various industries we cater to.

Indpro

Typically replies within an hour

Send Enquiry